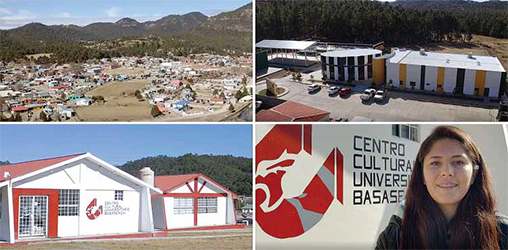

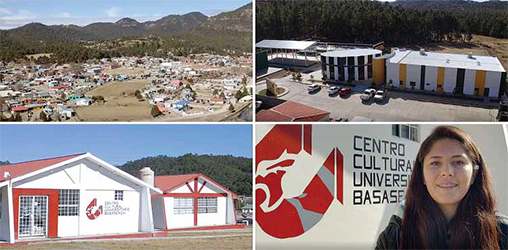

The community of Ocampo, Mexico, now has access to higher education through an extension to the

Technological Institute

The community of Ocampo, Mexico, now has access to higher education through an extension to the

Technological Institute

of Cuauhtemoc and the University Cultural Center of Basaseachi (bottom left),

thanks to the efforts of Agnico Eagle Mines.

(Photo: AEM).

The term ESG, the acronym for environmental,

social and governance, has

become ubiquitous in the mining business.

Some embrace it, some resent it,

and some are unsure about it. The truth

is that many publicly-held mining companies

have had robust sustainability programs

in place for 10 years or more, and

today’s ESG programs allows companies

to track and compare performance. Like

any initiative, ESG programs will fail if

they do not have support from the boardroom

to the front line.

The E defines how the company interacts

with the environment. The S

describes how the company treats its

employees and the stakeholders, who

are impacted by the mine or the mining

company. The G explains how the company

runs. Does it operate ethically? Is

the board and management trustworthy?

Do its actions match its policies?

A successful ESG program begins

with governance. Proper governance

provides clear accountability and transparency

by guiding a company’s management

and decision-making process.

Without a governance commitment, the

environmental and social aspects of the

program will not be as successful as

they could be. Each level throughout that

chain of command can impact ESG metrics.

That’s why it’s important to explain

the goals of the program and how people

can contribute.

Setting realistic and attainable goals

is also important. ESG programs track

performance, and document success and

failures. Recognizing a failure and daylighting

it allows the company to improve.

Safety as a Foundation

In its latest sustainability report, Frances

Fragos Townsend, corporate responsibility

committee (CRC) chair for Freeport-

McMoRan, discussed safety. “The

safety of our people is a foundational

Freeport value and our top priority,” she

said. “The health, safety and well-being

of our workforce is the responsibility of all

company leaders, as well as the board.”

Following a contractor fatality at the

Morenci mine and a marked increase in

recordable injuries in the first half of 2022,

Freeport’s CRC focused on identifying

and addressing emerging challenges.

“Management’s analysis of the increase

in recordable injuries in 2022 revealed

that many of the incidents involved new

employees or employees working under

new managers,” Townsend said. “This

challenge is particularly complex in North

America where we experienced a higher

than normal turnover rate during the

year and face continued labor shortages.

These insights are critical to directing

the appropriate resources and training to

where they can make the most significant

difference in safeguarding our people.”

As a result of this analysis, Freeport’s

management team has sharpened its

focus on safety training specifically for

new employees. They have placed a renewed

emphasis on active engagement

by supervisors and leaders in the field.

The oversight and interaction with contractors

has been strengthened to help

ensure they are meeting Freeport’s high

safety expectations.

Recovering from

Bad Decisions

A little more than a year ago Glencore

Ltd. pleaded guilty to foreign bribery

and market manipulation schemes. The

Swiss-based firm agreed to pay more

than $1.1 billion in criminal fines and disgorgement.

The guilty pleas were part

of coordinated resolutions with criminal

and civil authorities in the U.S., the U.K.,

the Democratic Republic of Congo and

Brazil. In its latest sustainability report

Glencore Chairman Kalidas Madhavpeddi

explained how the board’s investigation

committee spent the prior four years

overseeing the response to the relevant

investigations. He said the board and the

committee considered carefully the communication

of the resolutions to ensure

that the relevant details of these were

transparently set out so as to be clearly

understood by all stakeholders. The work

of Glencore’s investigations committee

continues today.

Cultural awareness is an important

concept that needs to be communicated

throughout all levels of the company. A failure to do so could be costly. In May

2020, Rio Tinto destroyed rock shelters

at Junkan Gorge, on the land of the Puutu

Kunti Kurrama and Pinikura (PKKP)

people in Western Australia. The company

fell far short of the values it espoused.

The company’s response was poor and

it damaged relationships with many of

its stakeholders. Three years later, the

company said it is focused on finding

better ways of working with partners, to

respect, value, celebrate and conserve

cultural heritage for future generations.

During November, Rio Tinto signed

a remedy agreement with the PKKP

Aboriginal Corp. and agreed to establish

the Junkan Gorge Legacy Foundation.

As part of the agreement, Rio

Tinto will provide financial support to

the foundation to progress major cultural

and social projects including a new

keeping place for storage of important

cultural materials.

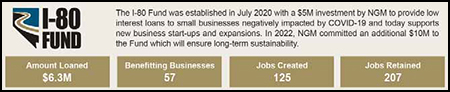

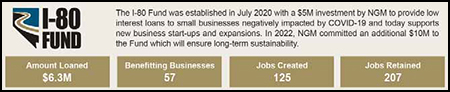

Nevada Gold Mines created a fund to support local small businesses in northern Nevada. (Image: NGM)

Nevada Gold Mines created a fund to support local small businesses in northern Nevada. (Image: NGM)

“While I am encouraged about the

progress we’re making, I know there is

still much work to do,” said Rio Tinto Iron

Ore CEO Simon Trott. “We need to keep

earning the trust of the people who give

us the privilege to operate on their land.

That applies not just in Western Australia,

but wherever Rio Tinto operates

around the world.”

Gender Balance and Equity

One of the common ESG goals among

mining companies is gender balance

or employing more women in what is

still a male-dominated industry. In May,

BHP reported that the female workforce

at the Escondida mine in Chile had

reached 31.4%, advancing towards the

company’s goal of reaching gender balance

by 2025.

BHP said it has found that inclusive

and diverse teams deliver safety benefits, have a better culture and are more

productive than other teams, which creates

a more harmonious environment

and makes BHP a better place to work

for all employees, regardless of gender.

Another problem mining companies

are trying to rectify is parity and discrepancies

in pay. Parity is something that

could easily be resolved during the onboarding

process. If a mine is hiring an

entry-level engineer, whether the position

is filled by a male or a female, the

pay should be the same. If the problem is

not resolved during the on-boarding process

it will manifest and only cause more

problems internally if the pay discrepancies

are discovered.

Recently BHP reported that a preliminary

review indicated that employees

across its Australian operations have had

leave incorrectly deducted on public holidays

since 2010. Approximately 28,500

employees were affected with an average

of six leave days in total that have

been incorrectly deducted from affected

employees over this 13-year period.

The company has estimated that

the cost of remediating the leave issue

will be as much as $280 million. “This

is not good enough and falls short of

the standards we expect at BHP,” said

Geraldine Slattery, president Australia

for BHP. The company has engaged

Protiviti to conduct a thorough review

of its payroll systems.

Investing in Education

A little more than eight years ago, Agnico

Eagle Mines (AEM) launched a program

to provide access to higher education

for the community surrounding its Pinos

Altos Complex, near Ocampo, Mexico.

Students of all ages now have access

to two higher education institutions. To

date, 180 students have completed their

bachelor’s degree and 13 have completed

their master’s degree.

During a community assessment

process undertaken by the Pinos Altos

community relations team, citizens expressed

frustration with the lack of access

to education. The nearest college

was 200 km from the area.

Pinos Altos, working in coordination

with local authorities, made the social

investments to support the development,

construction and operation of

higher-level institutions, beginning in

2015. Today, with AEM’s support, the

University Cultural Center of Basaseachi

now offers Master’s degree options.

And in 2020, an extension was added to

the Technological Institute of Cuauhtemoc,

which offers online educational

courses, which helped meet the needs

of students during the pandemic.

The Pinos Altos team also equipped

the community library with new computers

and internet access to the Institute’s

online educational system, helping students

and adults pursue college degrees

in business administration, psychology,

social work, industrial and systems engineering,

among other career options.

“As a result of these new schools,

and access to online education programs,

young people from the mountain

communities now have access to

higher education,” said Paola Cazares,

sustainability director. “They can develop

their skills and careers right in their

own region, improve the quality of life for

their families, and help create a sustainable

community.”

Supporting Small Businesses

Nevada Gold Mines (NGM) launched a

rural economic development initiative,

the I-80 Fund, with an initial investment

of $5 million in July 2020. The program

was established to provide support

through relief and recovery loans to eligible

small businesses affected by the

economic impacts of Covid-19. Counties

included are those located along the Nevada

I-80 corridor — specifically in Elko,

Lander, Humboldt, and Eureka.

Phase one of the program focused

on disaster relief and recovery loans for small businesses impacted by

COVID-19, with loans ranging from

$5,000 to $10,000 with a 2% interest

rate. To qualify for the program, businesses

must have been in operation

prior to January 1, 2020. Phase two of

the program, which started on January

1, 2021, is currently providing low-interest

loans to help develop new and grow

existing small businesses in the region,

thereby driving economic growth in

northern Nevada.

Since inception, the I-80 Fund has

provided $6.3 million of support for 57

small businesses in rural Nevada.

Environmental Compliance

Most modern mining operations have

well-defined environmental programs. It

begins during the permitting stages and,

as long as the mine adheres to the plan,

environmental compliance should not be

a problem. Where there is room for improvement,

however, is with emissions

and carbon intensity. For help in that

area, mining companies are looking for

support from suppliers.

FLSmidth was one of the suppliers to

recognize this need early. The company,

which supplies the full flowsheet technology

and service to the global mining

industry, established its MissionZero program to enable customers to become

carbon neutral in future. “We have reduced

our emissions 10% since 2020,”

said Wouter de Groot, head of sustainability

for FLSmidth. “The acquisition of

the mining technologies business from

thyssenkrupp has increased our scope 1

and 2 emissions somewhat but we are

confident we will be able to meet our target

to be carbon neutral for our scope 1-2

by the end 2030.”

Improving productivity is a central tenet

of sustainability, de Groot explained.

“Helping mines achieve this goal doesn’t

necessarily need to be complex and

expensive,” he said. “Incorporating advanced

process control (APC) systems

into existing operations can deliver clear

productivity and sustainability benefits

without major disruptions to production

or involve large capital expenditure.”

Citing two examples from copper

mining operations, de Groot demonstrated

the link between sustainability,

operational improvement, and profitability.

One of the mines installed LoadIQ

mill scanning technology on its SAG

mills, together with an APC system, and

achieved a 10% increase in throughput.

“Not only did this result in a $25,000/hr

increase in revenue it delivered a 9%

reduction in energy per ton of copper

produced,” de Groot said.

The other copper mine, located in

Chile where water is a scarce commodity,

added an APC system to its tailings

thickeners. This upgrade achieved a

14% reduction in water sent to the tailings

storage facility (TSF), which saved

more than 5 million cubic metres of water

per year. “This mine pumps seawater

more than 140 km to site for their process

water,” de Groot said. “This is an

expensive undertaking. We estimate this

results in a potential saving of $18 million

per year of water that would have otherwise

gone to the TSF.”

Mining companies could target several

areas in the processing flowsheet,

de Groot explained, which include optimizing

equipment efficiency, water and

energy management, process optimization,

recycling wear parts and media, and

training and awareness programs.

As part of its MissionZero sustainability

program to accelerate the development

and deployment of technology

solutions to increase sustainability in

the mining industry, FLSmidth has introduced

the ‘MissionZero Mine,’ which

consists of a series of commodity-specific flowsheets which articulates our

current and future R&D work and vision

for the flowsheet of the future.

“We are also focusing on pilot and

full-scale validation of REFLUX Flotation

Cell and coarseAIR flotation technologies,”

de Groot said. “We are also

developing specific technologies for

commodities like battery metals, where

further improvements in our pyro-processing

technology portfolio can lead to

further impact.”

Mining companies are looking to work

with suppliers whose goals are aligned.

FLSmidth aims to reduce its carbon intensity

across its value chain, de Groot

explained. “To that end, we have set

Science Based Targets (SBTs) addressing

our scope 1, 2 and 3 emissions,” de

Groot said. “We have a target that by

2035, 30% of our spend will be with low

carbon suppliers. Also, we aim to be carbon

neutral in our scope 1-2 emissions.

And finally, through our MissionZero

program, we are accelerating the development

and deployment of more sustainable

technologies that help miners

reduce their scope 1-2 emissions, which

are our scope 3 emissions.”

FLSmidth has set a social responsibility

goal of employing 25% women

throughout the company and in management

positions by 2030. That is an

ambitious goal for a company that employs

11,000 people. “It’s a challenging

target, but a necessary one,” De Groot

said. “We have implemented a number

of activities to improve our ability to

attract, retain and further develop our

female talent. These include mentoring

programs for upcoming female leaders,

engineering graduate programs to attract

female engineers, improvements in

our recruitment and significant steps to

close the gender pay gap. We need to

continue to do more, both as a company

and as an industry.”

De Groot said he is excited by the

growing interest of miners to test new

technologies. “We need to accelerate the

speed of adoption of more sustainable

technologies and this requires a collaborative

approach between OEMs and the

miners,” de Groot said. “Several pilot and

large scale projects have shown some

very positive initial results, which instills

confidence that we as an industry can

step up to the challenge to decarbonize

and reduce water consumption.”

Roadmap Toward Zeroexhaust

Emission Mining

Nouveau Monde Graphite (NMG) and

Caterpillar are mapping the development,

and testing of equipment and infrastructure

form NMG’s Matawinie mine in

Saint-Michel-des-Saints, Québec, Canada.

Equipment in commercial production

will be leveraged at first to support operations

during the pre-production phase

and early production years and are set

to be progressively replaced with Cat zero-

exhaust emission machines as they

become available.

The Cat-NMG development teams surround Denise Johnson, Cat Group President

The Cat-NMG development teams surround Denise Johnson, Cat Group President

(sitting), and Eric

Desaulniers, founder, president and CEO, NMG (also sitting).

(Photo: NMG)

With the objective of having realized

a complete all-electric transition

by year five of Matawinie’s commercial

operations, technical teams will work in

close collaboration to test Caterpillar’s

Early Learner models and pilot units

and support technology development.

NMG will make use of these machines

in actual mining operations and gather

data from on-site use in a variety of

weather, terrain, and operational conditions.

Feedback from NMG’s mining

operations should help further advance

the development of electrified machines

and sites.

“Not only will we benefit from Cat’s

stellar expertise, renowned products,

and latest technological developments,

but our team will also be at the forefront

of the electric revolution in the sector,

sharing insight, testing equipment for

further optimization, and providing battery

materials to support electrification

beyond our mine,” said Eric Desaulniers,

founder, president, and CEO of NMG.

“This collaboration truly reflects our vision for leadership and unified efforts to

advance responsible mining practices

and global decarbonization.”

Depending on the commercialization

of Cat zero-exhaust emission machines,

Caterpillar will reserve production

slots, which should enable NMG

to benefit from timely deliveries and

technology enhancements throughout

the duration of the contract. The agreements

encompass machines such

as hydraulic excavators, haul trucks,

wheel loaders, dozers, and motor graders,

as well as charging and energy

storage infrastructure and equipment

maintenance services.

NMG and Caterpillar’s Job Site Solutions

have agreed on a novel solution to

reduce NMG’s initial capital intensity for

the Matawinie mine. The solution provides

access to equipment through an

hourly fee based on usage and includes

asset management support to help improve

uptime, predictability, and efficiency.

Caterpillar, together with Toromont

Industries Ltd., an authorized Cat dealer,

will manage the maintenance and repair

strategy for the equipment to maximize

machine availability. NMG will also have

the opportunity to lease or acquire machines

if desired, through Toromont.

“This project is an exciting one as it

highlights what is possible when an effective

energy transition roadmap is

implemented that bridges the traditional

product line to an integrated, electrified site of the future,” Denise Johnson,

group president for Caterpillar, said.

In 2022, Cat unveiled its first prototype

of a battery-powered large mining

truck, demonstrating the most recent

advancement in technology and the extent

of electric solutions by operating fully

loaded to its rated capacity. Through

this next stage of their collaboration, Cat

intends to help NMG advance the Company’s

Net Zero objectives.

Cat has also signed an offtake agreement

with NMG for its active anode material

to be produced at the company’s

Bécancour Battery Material Plant. “A

secure, resilient, and sustainable supply

of battery materials is critical to actualizing

the opportunities that electrification

represents for our customers,” said Rod

Shurman, senior vice president for Caterpillar

with responsibility for the Electrification and Advanced Power Solutions

Division. “This collaboration with NMG

is an example of how Caterpillar is intentionally

building out our value chain

to support our customers’ sustainability

objectives and further establish our role

in the global energy transition.”

NMG’s planned all-electric operations

powered by renewable energy

combined with clean processing technologies

are set to generate advanced

materials with an exceptionally low climate

change impact, in line with global

decarbonization efforts.

U.S. Borax Becomes First

Open-pit Mine to Switch to

Renewable Diesel

Rio Tinto has completely switched

heavy machinery at its Boron mine in California from petroleum-derived diesel

to renewable diesel, or hydrotreated

vegetable oil (HVO), making it the first

open pit mine in the world to reach this

milestone. Rolls-Royce is supporting

the mining company in its endeavor and

has been testing mtu engines on HVO

in haul trucks and wheel loaders since

2022. During the 2,000 hours of operation

to date, Rio Tinto found that the engines

running on the renewable diesel

deliver similar performance and reliability

to traditional diesel.

The switch to renewable diesel at the

Boron mine is expected to reduce CO2 by

up to 45,000 metric tons per year, equivalent

to annual emissions from about

9,600 cars.

Close cooperation between Rio Tinto,

Rolls-Royce and Neste led to the

success, explained Sinead Kaufman,

CEO, Rio Tinto Minerals. “This is an excellent

example of what happens when

internal and external partners collaborate

toward a carbon reduction goal,”

Kaufman said. “Support from the state

of California has also been incredibly

important, as without their vision, this

would not have been possible.”

“The conversion of the first open pit

mine to HVO is an important milestone,”

said Cobus van Schalkwyk, director

global mining for Rolls-Royce Power

Systems. “With further sustainable offerings,

such as reman or re-motorization

solutions for vehicles or microgrids for

energy supply, we are ready for the further

future decarbonization at the mines.”

The initial trial to convert a Borax haul

truck to renewable diesel was conducted

in collaboration with fuel manufacturer

Neste. Rio Tinto U.S. Borax used

Neste MY Renewable Diesel during the

trial. Neste MY Renewable Diesel is

made from sustainably sourced, 100%

renewable raw materials such as waste

cooking oil and animal fat waste and can

reduce greenhouse gas emissions by

up to 75% over the lifecycle of the fuel

compared to conventional diesel. The results

of the trial showed that a haul truck

powered by mtu engines running on renewable

diesel had similar performance

and reliability to haul trucks running on

conventional diesel.

GHG Alliance members met recently at Komatsu’s AZPG. (Photo: Komatsu)

GHG Alliance members met recently at Komatsu’s AZPG. (Photo: Komatsu)

Other benefits of renewable diesel

include clean combustion with a reduction

in particulate emissions of up to

40% in mobile applications and a reduction

in NOx emissions by an average of

8%. HVO is a drop-in fuel, according to

Rolls-Royce, which means that the existing

diesel plant infrastructure can be

used unchanged for its use, and no engine

hardware or software modifications

are required.

GHG Alliance Makes

Progress

Komatsu recently gathered members of

the company’s Greenhouse Gas (GHG)

Alliance at its Arizona Proving Grounds

(AZPG) to share progress and highlight

knowledge gained since the EVX (battery-

powered haul truck) was showcased

at MINExpo 2021.

At the event, alliance members had

the opportunity to directly observe advancements

made over the past year

related to the performance and sizing

of batteries, engage in a discussion on

recent progress within the regulatory

environment, and learn how Komatsu

plans to leverage the company’s trolley

system to advance understanding of

battery truck performance in a dynamic

charging environment. Specifically, alliance

members saw the upgraded EVX

(battery) truck running a circuit on battery,

static charging of the battery with

the truck hooked up to the trolley line

via pantograph, and a run up the trolley

line highlighting the battery being

charged and increased speed in the

dynamic environment.

The GHG Alliance was created to

bring together mining industry leaders to

work toward a shared goal of delivering

zero-emissions equipment solutions. Alliance

members have since been working

to advance Komatsu’s power agnostic

truck concept for a haulage vehicle that

can run on a variety of power sources including

diesel engine, battery and even

hydrogen fuel cells with both static and

dynamic charging capabilities.

Since the alliance was formed,

membership has steadily grown and

now includes the following companies:

Antofagasta Minerals, BHP, Boliden,

Codelco, Freeport-McMoRan, Grupo

Mexico, Kinross, Rio Tinto, and Teck

Resources.

“Our alliance members were able

to experience the substantive continuation

of a journey that was started at

MINExpo 2021 as we have advanced

our understanding and development

of this critical technology,” said Pat

Singleton, product director for Electric

Drive Trucks. “The past year has been

filled with collaborative efforts between

alliance members, technology partners

and other industry stakeholders dedicated

to achieving our common goals

of delivering zero-emissions solutions

to the mining industry.”

Komatsu said it is committed to minimizing

environmental impact through its

business, targeting a 50% reduction in

CO2 emissions from use of its products

and production of its equipment by 2030

(compared to 2010 levels) and a challenge

target of achieving carbon neutrality by 2050.

As featured in Womp 2023 Vol 06 - www.womp-int.com