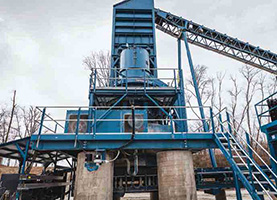

A custom-designed Weir Minerals Trio crushing plant helps double gold

recovery at Lluvia de Oro in Mexico. (Photo: Weir Minerals)

Crush It, Maintain It, Control It

We ask seven companies, what’s new in cone crushing equipment,

tools and support services

By Carly Leonida, European Editor

Today, miners want more visibility around their cone crusher’s overall performance so they can optimize and improve their operation. They want to understand the control systems, which are constantly measuring a multitude of data and raising warnings or even alarms to provide an early indication if there’s anything potentially wrong. Ultimately, the target is to significantly reduce downtime. Ideally, the only downtime would be to change wear parts and, when that occurs, there’s an expectation that it’s carried out as quickly and seamlessly as possible.

Sebastian Rakoczy, global product manager for Crusher Products at Weir Minerals, explained: “Many of the sites we service are remote, which creates some logistical challenges. When a customer needs a spare part that they don’t have on hand, they want it immediately. Understandably, they want to avoid long periods of downtime while they wait for shipping and delivery. We try to avoid this scenario by understanding our customers’ spare parts consumption and monitoring their cone crushers’ performance. The local Weir Minerals service team works closely with mine operators to pre-empt wear part replacement requirements, while also providing whatever support or equipment they need to avoid unplanned downtime.”

All Trio cone crushers are commissioned by a Weir Minerals specialist. The team completes or supervises the installation, then runs training sessions to explain the technology to the customer and go through the installation, operation and maintenance manuals in detail. “We run through maintenance schedules and demonstrate the importance of preventative maintenance as a means of ensuring optimal performance,” Rakoczy said. “These trainings are normally run on-site, but, when that hasn’t been possible over the past 18 months, we’ve conducted them remotely.”

New Models, New Deliveries

From Weir Minerals

Weir Minerals recently supplied a Trio

TP600 cone crusher into Chile. The team

remotely coordinated the commissioning

from the U.S. because of COVID-related

travel restrictions. The communication

and control software were also adjusted

remotely, which is no mean feat.

“The customer was happy because we delivered what we said we would, despite the obvious challenges,” Rakoczy said. “Our European commissioning specialists are based in Poland and COVID-19 has restricted their ability to travel, at times. Weir Minerals had some new Trio TP260 cone crushers go into operation in Morocco and the commissioning specialists were able to remotely monitor the machine’s performance and provide support to the local service team. They were in almost constant contact, troubleshooting problems, discussing any concerns and honing the machine’s performance.

“At the end of the day, the customer was satisfied because they received two new, operational Trio TP260 cone crushers and, from our perspective, we’ve got a local team that’s gained a huge amount of knowledge and experience.” COVID has also allowed Weir Minerals to more fully explore the benefits remote access can provide to its customers. Rakoczy explained: “As an OEM, we know these machines inside-out — we designed and built them, after all. So, understanding how they’re performing at each specific site, with all its unique challenges, whether related to the application, the plant around the cone crusher or the weather, allows us to provide the best possible support to ensure the machine is performing at its optimal level.”

Weir Minerals’ Synertrex digital ecosystem is also paving the way for the future “connected” mine. In recent years, the IIoT has been facilitating a paradigmatic change in how mining companies perform their day-to-day tasks, carry out maintenance and run their processes. Fast evolving IIoT technologies, together with advanced data processing techniques that utilize artificial intelligence, machine-learning models and neural networks (i.e., a series of algorithms that aim to recognize underlying relationships in a set of data through a process that mimics the way the human brain operates) are driving a shift toward more proactive maintenance, planning and execution, resulting in unprecedented plant optimization.

Weir Minerals recently added the Trio TC84XR cone crusher to its product range. This is the latest iteration of the live-shaft design. It has been upgraded and features the latest technology to ensure that, given the right application, it will remain an integral part of flowsheets long into the future. Going forward, Weir Minerals will be focusing on the optimization of its control systems to make them as simple and easy-to-use as possible.

Rakoczy said: “Through this process, we’re constantly refining existing elements, as well as looking for things to improve. The Trio TC84XR cone crusher is a good example of this. Live-shaft cone crushers have obviously been on the market for decades, but some of the Trio TC84XR’s design features make it a truly modern machine. And we’ll see those design elements cascade down through the range of Trio cone crushers.”

Weir Minerals continues to see a lot of interest in its Trio TC live-shaft cone crushers from central Asian and Russian miners due to the harsh conditions and challenging applications they face. There are many legacy live-shaft crushers that will need to be replaced in the coming years, and Rakoczy said the Trio TC84XR machine provides a simple, straightforward replacement option.

Westgold Resources’ Bluebird Gold mine in Western Australia recently took delivery of a Trio TC51 cone crusher. The mine was having production related issues caused by higher than anticipated pebble loads in the mill circuit. The Weir Minerals’ team recommended the TC51 crusher to take the pebble load off the mill as its thick liners and large feed opening are well suited to pebble crushing. With the new arrangement, the pebble load on the mill decreased and the plant production increased by as much as 25%.

At Lluvia de Oro, Mexico, Weir Minerals designed a custom crushing plant utilizing Trio equipment, including a TC series cone crusher, which helped the operation double its gold recovery. And, at the Compañía Minera Kolpa S.A (Kolpa) polymetallic mine in southern Peru, the Weir Minerals team delivered a Trio TC36 that reduced the circulating load and processed up to 1,200 metric tons per day (mt/d), which was a 50% increase in throughput. The life of the wear parts — the mantle and bowl liner — also doubled, while energy consumption decreased by 10%.

“We commissioned and installed a Trio TP900 cone crusher in an iron-ore application in Tangshan City, Hebei Province, China, which increased availability by 10%, compared with the incumbent crusher,” Rakoczy said proudly. Rakoczy believes there is still scope to improve energy consumption in cone crushing applications too. “The desire to find more sustainable ways of doing things is a major driver of innovative engineering within Weir Minerals. We’re always examining ways to make the machines more efficient,” he said. “We’ve seen that with the Enduron high-pressure grinding roll (HPGR), which can reduce energy consumption by up to 40%. The same sustainability goals that have underpinned its design and manufacture are also driving improvements in the range of Trio cone crushers.”

FLSmidth Doubles Down on

Control and Maintenance

Bill Malone, global product manager,

mining crushers at FLSmidth, said the

past few years have seen heightened

demand for larger machines to deliver

higher capacities, coupled with control

systems that ensure these machines are

achieving results as efficiently and economically

as possible. Longer times between

service intervals with optimized

liners, materials and chamber designs, to

deliver the lowest-operating-cost-per-ton

are also requested, as well as safety features

that improve and simplify routine

maintenance and rebuild schedules.

“Since our designs are all relatively recently optimized, FLSmidth is concentrating on upgrading and improving our peripheral offerings,” he said. “We’ve added new control systems with enhanced features, which include the ability to not only detect an overload situation, but automatically correct it, long before the operator can in most cases. “Additional features have also been added to allow adjustment of the crusher to compensate for product size variances. Whether you are looking to make a single- size or just maximize reduction ready for the next step in the process, we can now address these requirements through our automatic control system.”

FLSmidth’s latest condition monitoring system offers additional features to monitor and react early to potential performance issues such as overloads, bearing condition changes, vibration, oil quality, hydraulics, etc. Together, these technologies and features are a major step in ensuring that cone crushers can be operated at their maximum potential and kept in that state through a process of early detection and scheduled maintenance, rather than reacting to an issue once it has reached the point where production has to stop.

New service tools have recently been added to assist in the replacement of head assemblies, keeping downtime to a minimum and maximizing safety when changing out major components, as well as a new hydraulic lock-nut tightening tool to ensure reliable and consistent mantle liner installation. Like its peers, FLSmidth has found that COVID travel restrictions have limited site access over the past two years. However, the company has risen to the challenge. “Through our network of regional service suppliers, we have been ensuring that our customers stay in contact by way of telephone, email, and internet, where physical attendance is not always possible. And that they’re aware of who and where we are, and how to get in touch with us,” Malone said.

“We can interact with customers on most web meeting platforms, and ensure we have suitable personnel available who can identify problems and provide remedial responses. This is also easy to backup in today’s communications with data, videos and live discussions where necessary. “We can even support live cameramounted feedback to provide more precise support and troubleshooting. While this is not so much of an issue now, as we see COVID receding, it was utilized frequently when restrictions were more stringent.”

Like most service and support partners, FLSmidth has developed systems that offer its customers the ability to remotely operate and monitor their crusher or indeed their entire plant. Malone explained: “With internet connectivity and systems such as SiteConnect, we can offer the ability to receive instant notifications on mobile devices advising of unexpected events or giving access to live performance data. We also offer a 24/7 Global Remote Service Center capability, which provides remote monitoring and analytics that can reduce unplanned downtime, and we have paid careful attention to cybersecurity to ensure our customers data is safe, confidential and unbreachable.

“With COVID and the additional restrictions this imposes, we have recently seen a marked interest in the number of projects we are being asked to supply these capabilities and in retrofitting them to existing plants to improve their operational capabilities and reliability during times when physical attendance may not be possible.”

Training is an important part of FLSmidth’s crushing portfolio. The team endeavors to train operators and service personnel from the plant where new equipment is installed, so they can learn how to operate and maintain the equipment safely and in the most productive manner. “We can also assist customers in optimizing their operation and maintenance procedures to handle local site conditions,” Malone added. “This can be done on-site before, during and after commissioning and then backed up by in-person, or remote assistance from our regional offices/super-centers, where our experienced service personnel are based. As mentioned previously, we also have our global remote service center, which can be subscribed to and offers 24/7 access to assistance when required.”

FLSmidth currently has several large cone crushers being installed and plans to release case studies soon. Through its dedicated facility in Europe, MAAG, Malone said the company was able to replace a crusher that was damaged at sea while on its way to a customer in just four weeks. “We were able to achieve this, in part, due to our stocking policy for large cones, despite the supply chain issues being experienced due to COVID,” he added.

Superior’s New Patriot

Heads to Site

At MINExpo International in September

2021, Superior Industries debuted

its new P800 Patriot cone crusher. The

first unit is now heading into an ironore

operation, with plans for it to go live

this spring. The P800 is a 203,000-lb.

(92,000 kg) model with a 14.2-in. (360

mm) maximum feed opening and maximum

capacity up to 1,600 t/h.

Web-based meetings have proven an effective way for Superior to continue supporting customers through COVID-19. Although Gray strongly believes that nothing can replace physical site visits and face-to-face meetings. “We’re seeing more and more geographical areas carefully opening back up, and we’ve been blessed to travel to several sites in person,” he said. “On-site training is most effective for mining operations because it’s hard to pull trainees away from sites. Both application and service training are included as part of our sales or as requested by sites. Additionally, we have several video-based topics available on-demand.”

While travel might be opening back up, remote control and monitoring are here to stay. “Our Vantage Automation system tracks several settings to monitor and improve efficiencies, sounds alarms for harmful conditions and allows owners and operators to precisely control their machines,” Gray added.

Small But Mighty,

Sandvik Cones

“We see a lot of requests at the moment

around reliability and efficiency on cone

crushing equipment,” Mikael Lindberg,

product line manager for digital solutions,

in Sandvik Rock Processing Solution’s Stationary Equipment division, said. “Clients

want really robust designs to make

sure that the equipment is reliable, predictable,

and that it works according to

their initial design expectations. The

other focus we see is on sustainability

through lower energy consumption, noise,

dust water, etc. The whole business is really

thrusting in that direction.”

The Sandvik cone crusher is relatively small — around 80 mt — compared to other machines in its class, which weigh around 130 mt, but the output over time is similar thanks to the efficiency of its design and self-adjusting automation. “Equipment availability is very important, as is knowledge transfer,” Lindberg said. “Every time a machine is standing still, it’s basically wasting production. At the moment, it’s hard for customers in the mining segment to attract and retain the right people, so we are continuously developing features and technologies that minimize the interaction of personnel around the equipment.”

Sandvik recently launched its Reborn Concept, which replaces old cone crushers with newer models in a simple plugand- play switch. “When a machine gets old, the reliability of the equipment drops, the cost of operation increases, and also the need for interaction (maintenance) increases,” explained Lindberg. “So, we have a packaged solution where mines can switch just the cone crusher out without needing to change the systems surrounding it. They can keep the oil tank, the automation system, the conveyors and infrastructure…

“We’ve been running the Reborn program successfully for some time now and it’s really addressing the sustainability aspect. The package includes installation, supervision, and training plus an extended warranty and service agreement. We will also upgrade the automation and connectivity systems so that mines can take advantage of all the digital features of new models too. It’s everything they need to make that switch easy and cost effective.”

“In the long term though, it’s important to mix in some face-to-face sessions where possible to build understanding and trust. Good training requires a mix of theoretical and practical elements, and it needs to be continual. Technologies move quickly and people are still switching jobs, so there is the potential for knowledge to be lost from teams. We’re trying to navigate that with our training and service packages, but it’s something that mines need to stay on top of too.”

Sandvik has also launched a digital service — SAM by Sandvik — which has been co-created with customers. It is an ever-evolving digital service designed to support operational excellence in a customer’s crushing and screening plant. Although SAM has a focus on operators and service technicians, it is designed to support every level in the operation, including the plant manager, maintenance manager and purchaser.

Through the SAM service, customers can view their data in near real time on a split screen with a cutaway diagram of their machine. This enables them to “see” what’s going on inside relative to the performance, which Lindberg said is helpful for technical training, refresher courses and ongoing development. And, if they have any issues, both customers and Sandvik technicians can look at the same data set when troubleshooting. If SAM foresees a maintenance or performance issue, it will alert the operators who can verify the issue and, if necessary, take action as directed. The algorithm uses this “supervision” or input to learn and improve its accuracy for future occurrences.

“SAM might not be as good as having a technician with 30 years-experience sat next to you yet, but it’s the next best thing and the more clients use it, the more accurate it will get,” Lindberg said. “Also, the platform uploads data to our secure cloud and anonymizes it to draw insights from mines across the globe. In time, it’s accuracy will be second to none. It’s our way of helping to bridge the skills gap that many mines are facing at the moment.”

Optimum Crush: Training

Tomorrow’s Technicians

Milwaukee-based Optimum Crush provides

third-party engineering services, training

and support for cone crushers. President and Founder Jerrod Dulmes spoke about

current requests and challenges.

“Today, our mining clients are asking

for fast response times to technical

support,” he said. “They are finding

large companies offering more products,

which is diminishing their detailed product

knowledge. This is especially needed

during unexpected breakdowns or complex

troubleshooting.”

Preventive maintenance is nothing new, but it’s more important today than ever because it’s harder to bring in contractors in sudden breakdown situations. Today, many mines are investing heavily in predictive measures to counter this. Additionally, some miners are seeing the value of remotely monitoring their equipment and are farming some of that responsibility out to support companies. Dulmes explained that over the past two years, COVID restrictions have limited the number of outside technical experts who could visit sites. Experts will notice signals and indicators that a general worker might not, and so removing that capacity has meant that some mines have seen an increase in breakdowns or decrease in productivity.

“Miners are asking for more product- specific training to help coach their teams on what to look for and what is correct,” Dulmes said. “When you are working on equipment every day that very slowly wears, it can be hard to see the clear difference between good and bad, so educating staff helps them keep a better eye on the machine. The focus needs to be on using technical experts to train mine staff so those people can better troubleshoot and support the specialized equipment.” For engineers and trainers, travel has become much more stressful as it now requires significant planning and paperwork. Dulmes said: “It’s very complicated when crossing international borders because COVID PCR testing must be done 24 hours before travel. This is even more challenging on the return because our team members are dependent on the mines to help connect them to test facilities that can offer that service. Some miners are now offering this service directly on site as a result.”

Optimum Crush offers 24/7 technical support to mines via email, phone, and video conferencing. It also offers on-site technical support for cone crushers and auxiliary equipment.

“Our specialty is in FLSmidth and Telsmith cone crushers and, because of the mechanical similarities between the FLSmidth and Metso cones, we can certainly also support Metso cone crushers too,” Dulmes said. “Training is very flexible and can be classroom-type and/or hands on. We prefer a blend of both where we can train on site in a classroom atmosphere with the ability to then go out to the crusher and get our hands dirty with the class. We had made a plan to offer training classes in our Wisconsin headquarters but, since COVID, that has evolved into MS Teams video training.”

R&D is a major part of Optimum Crush’s budget and Dulmes said there are dozens of projects in the pipeline. “Nearly all of our R&D projects are customer driven, where customers tell us about a need to make a part last longer, prevent cracking, stop leaking or be faster to change,” he said. “We welcome miners to contact us to share what their specific needs are. Chances are we already have a solution but, if not, we would love to discuss setting up a project that can address it.”

Extending Wear Part Lives

and Increasing Capacities

When it comes to wear parts for cone

crushers, Portland, Oregon-based Columbia

Steel has developed creative ways

to source materials and hold costs to a

reasonable level whatever that may be

today. The company has also developed

a high-output mantle that several mines

are currently testing with encouraging results.

Columbia Steel is well known for

its wear parts and liners, and many mines

rely on its expertise to get the most from

their cone crushers.

Replacing worn parts for cone crushers consumes a lot of raw materials. “We work with the mines to recycle wear parts,” said Doug Henderson, product engineering director for Columbia Steel. “If they are our parts, we know the composition, so we will not need to add as much alloy.” Henderson noted that 70% of a manganese steel heat is made from re-melted cast material including worn parts and the rest of it is adding new material.

Manganese grade is a really important factor for cone crusher wear parts. Columbia Steel offers a 24% manganese grade, which is higher than most of the offerings on the markets these days, Moehnke explained. “Grades of 18% and 21% are quite common,” Moehnke said. “Manganese steels harden as they deform. In a crusher application, where it’s getting pounded all the time, the steel is deforming and work hardening. The higher manganese grade, if the recipe is right, will make that surface harder and provide more wear life. It is a recipe. You can’t simply add more manganese without adjusting some of the other aspects of the alloy. We have conducted a lot of research to refine the adjustments that allow a 24% manganese grade and give those wear parts that hardening ability and extend their lives.”

Columbia Steel has developed a high-output mantle for cone crushers. The mantle has spiral flutes or feed arms that improve the throughput. “We have run several tests in the field and our solid flow simulations are showing a 13% increase in throughput with basically the same settings, the same material and the same output settings,” Moehnke said. This product is available to the mines now. “We had a few test installations at the mines,” Henderson said. “We struggled to find good test sites with belt scales, but the ones that performed the tests for us showed some very encouraging results. We know they are working well. At some mines, they overwhelm the crushers below them. Without scales and instrumentation, however, it’s difficult to understand the true quantity in the field.” Modeling yields a more precise figure. “That’s the primary reason we invested in modeling,” Moehnke said. “All of our testing to date has been very positive. Everybody that has run one has said it runs more material, but they can’t give us a number as far as how much more material.”

Columbia Steel builds the mantles. “The use of a high-output mantle depends on what patterns we have for the mines and we’re getting more and more patterns all the time,” Henderson said. A pattern is the wood shape of the part they cast. Sand is packed around the pattern in a mold. The mold is opened, the pattern is removed and the mold is closed. Molten steel is poured into the cavity created by the pattern.

If they have a pattern for a customer and they want a high-output mantle, Columbia Steel would add the feed arms to the pattern. If a new customer wants a new machine, they would build a pattern with those feed arms on it. When they pack the sand around it, it would have that feed arm shape added to the mantle. Patterns are expensive and they are bulky, Moehnke explained. “We’re talking about a 7-ft cone crusher — that’s a very large piece of wood that has to be stored somewhere,” Moehnke said.

Crusher OEMs are making new models of cone crushers, hoping the older machines will be replaced with the newer style products. “They have also discarded their older patterns because of space constraints,” Moehnke said. “Columbia Steel sits on 88 acres. We have a lot of space to store patterns and we have kept the older style crusher patterns. Companies not looking to upgrade their crushers will likely have more trouble finding liners for those and we’re well positioned to help them. We will be able to make the old-style cone crusher parts for many years to come.”