Aggressive slope designs require comprehensive design and analysis as well as continual monitoring to

maintain a safe, productive environment. (Photo: Seequent)

Designing the Mines of Tomorrow

We ask four leading software vendors, what’s new in pit slope design and analysis?

By Carly Leonida, European Editor

Recent advances in software have been a key enabler. More robust geotechnical models, 3D visualization, better representation of the rock mass behavior, speedy handling of vast data sets and the ability to automate tasks are just a few of the improvements. The widespread use of cloud computing also means that, today, very large models can be accessed by multiple users in different locations, and web licensing has improved practitioners accessibility to slope design and analysis packages on demand.

Decade of Rapid

Development

Slope analysis software is used to explore

the processes and mechanisms controlling

the behavior of a physical system.

Once the engineer understands the critical

mechanistic controls, they can more

confidently evaluate solutions on which a

final design is based. Design software, on

the other hand, is focused primarily on

rapidly sizing the components of a design

without the underlying mechanisms and

controls being fully transparent.

According to Chris Kelln, director for geotechnical analysis, GeoStudio, at Seequent, the breadth, rigor and sophistication of slope stability analyses have advanced markedly in the last decade. “Two examples of this are in the types of analytical approaches and the dimensionality of the analyses,” he said. “Historically, the predominant method of slope stability analyses was the limit equilibrium (LE) method. Although this continues to serve the industry well, it’s now possible to supplement that approach using finite element- based methods, such as the stressbased limit equilibrium (SLE) and shear strength reduction (SSR) methods. These provide a comparative solution to the LE method and also illuminate mechanistic controls on the stability of the slope.”

Of course, increasing the sophistication of the analyses also comes with increased computational cost and associated numerical challenges. The 2D LEM approach offers speed and simplicity of analysis but is sometimes incapable of capturing 3D effects that are common to some types of problems.

Murray Fredlund, senior strategic advisor for geotechnical, PLAXIS LE at Seequent, said: “Advancements in 3D LE analysis have increased our ability to assess spatial variability of open-pit stability. More specifically, this new analysis capacity is the result of the implementation of 3D LEM methods, and the ability to sweep such analysis methods around a 3D structure and provide an indication of spatial slope stability.”

Although more computationally demanding, there are unique stability problems in which the controls associated with 3D effects are important to evaluate. These may include the effects of topography, anisotropy/geostrata layering, water tables, bedding planes and faulting, and complex stress histories. Ultimately, such improvements to analysis capabilities have led to a simulation that has increased alignment with the physical world and therefore leads to improved slope design and increased ore recovery.

User interfaces have also advanced. Users can now incorporate multiple geometries and analyses in the same file. The ability to conduct sensitivity and probabilistic analyses has improved, and functionality to interrogate results has become much more user-friendly. As a result, analysis software is more approachable and useful in dayto- day practice. Full 3D open-pit models can be constructed in hours or days and analyzed with advanced reporting methods available at the engineer’s disposal.

Micha van der Sloot, senior manager for user success, geotechnical, PLAXIS at Seequent, added: “Recent developments in automation offer new possibilities for users to automate their repetitive tasks. As younger generations of geotechnical engineers are open to programming in modern languages like Python, many new possibilities and standardization opportunities arise, which really helps in enhancing repeatable quality while at the same time reducing manual work. This frees up the engineer’s time and opens new possibilities to connect geotechnical analysis software with other automation tools and data services.”

Seequent Homes in on

Interoperability

With Seequent joining Bentley, there are

now four main products in the company’s

portfolio for slope stability analysis:

Leapfrog, a geological modelling and visualization

application; GeoStudio, a fully

integrated, multi-physics software application

that supports multiple-geometry

analysis (1D, 2D, 3D, and axisymmetric);

PLAXIS LE 3D, a 3D LEM slope stability

solution for open-pit mines; and PLAXIS

2D/3D (FE), which provides advanced

stress-strain modelling capabilities for

rock and soft soils.

Over the past 18 months, the team has focused on improving stress-strain analysis capabilities for different rock types within its products, and interoperability with Leapfrog via Seequent’s cloud-based data management system, Seequent Central. Kelln explained: “In 2018, we released a redeveloped finite element solver built on modern architecture for the GeoStudio heat and mass transfer products. The re-release of the stress-strain application in 2020 completed this journey, with a more rigorous formulation brought into the modern architecture. As such, we expanded the constitutive model library to include Hoek-Brown and strain hardening-softening, optimized the shear strength reduction stability algorithm, and increased the classes of problems that can be solved with GeoStudio. We also improved our LE stability package for rock by introducing the Compound Strength material model and improved the Hoek-Brown material model.”

Going forward, the team believes that geotechnical building information models (BIM) will become a critical part of openpit design and analysis. Kelln said: “A geotechnical BIM enables rapid reinterpretation of site conditions and evaluation of design alternatives by enabling the geotechnical engineer to rapidly create numerical models drawn from this ‘single source of truth.’ Slope stability modelling software needs to be a fully integrated part of this ecosystem.”

Hexagon Integrates Slope

and Safety Platforms

In recent years, interactivity from reality

capture and resource models have also

brought slope design closer to reality and

have provided optimization for accessing

reserves. The advantage of 3D design interfaces

is that they take all parameters

into account; users can now visualize and

manipulate data in the same space as

their slope design tasks.

Over the past year, Sanchez and his team have worked with Hexagon’s safety and monitoring solution developers to create an integration that encompasses slope monitoring with collision avoidance and planning. This relationship is commonly seen as a workflow at mines, but the teams have also taken it a step further so that solutions can transfer data to each other in real time, redesign slopes to correct issues and keep personnel safe.

“Hexagon’s focus for the foreseeable future is on integration, connecting all of our systems and having one platform that can take customers from exploration to production,” Sanchez explained. “Slope design and drill and blast processes are so closely related. We want to improve data flow between these and other departments. “In the future, we see slope design and modelling becoming increasingly intelligent and leaning more on machine learning. We hope to see a day where engineers and geologists can save time by making complex decisions based on autonomously created designs and data analysis.”

Maptek: Monitoring Makes

for Better Designs

Maptek has been using laser-scan data for

feeding into slope design for more than 10

years. The geotechnical tools in Maptek

PointStudio software include mapping and

analysis features that operate on the pointcloud

data to better manage slope risk in

surface and underground mines.

“Slope stability has a real impact on

risk and hence safety in open-pit mines.

The better our understanding of slope stability, the better placed we are to design

and build safe operations for protecting

mining personnel, equipment and the environment,”

said Mike Husbands, head of

customer experience at Maptek.

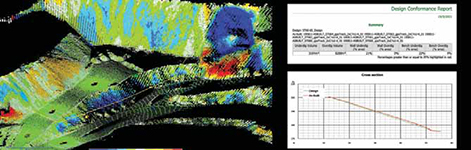

Maptek’s mobile, laser-based Sentry slope monitoring system can be deployed to monitor mine surfaces such as pit walls, slopes, benches and ramps as well as underground convergence and subsidence. Sentry uses light detection and ranging (LIDAR) data to provide a 3D contextual recording of slope movement. Pit or shift supervisors can access conformance information via mobile devices, creating a real-time decision support and quality control system. This allows adjustments to be made before problems arise to ensure efficient overburden removal and maximum mineral recovery. Empirical databases can also be used to predict slope behaviors for a design, informing safety mechanisms and design rules.

From Conformance to

Advanced Analysis

The Geotechnical Tools add-on to Maptek

PointStudio provides geologists and geotechnical

engineers with tools for analyzing

slope structures and undertaking

kinematic analysis. Working directly on

laser-scan data ensures accurate and informative

geotechnical reporting to guide

mine planning and operational decisions.

Maptek has also developed an easyto- use Inter-ramp compliance tool that allows operations to ensure as-builts conform to designed wall angles and bench widths to maximize safety. Accurate designs for catch bench width, inter-ramp slope angle and overall bench slope angle are required for safe excavation and economic optimization of highwalls. Conformance reporting can be added to PointStudio and PointViewer licenses for quick comparison of design surfaces to as-builts. Reporting on under dig, over dig and percentage of volume variance for each block provides immediate and clear understanding of design conformance. Users can customize templates, attach photographs and documents, and export professional conformance reports to support decision making in any operation.

The latest Maptek design conformance tool is delivered on FieldHHC, the laser scanner control tablet. Using this, users can recognize in the field whether pit walls are conforming to design, and issues can be resolved more quickly when it is not necessary to wait for office processing. Dynamic reporting and cross section output mean everyone stays up to date on how designs are performing, and production is not delayed.

The latest Maptek PointStudio software release includes enhanced functionality to improve the automation of daily tasks. Working off current, accurate data provides decision support for improving slope stability. Inter-ramp conformance reporting has also been improved. Slope monitoring includes enhanced interoperability and user experience for monitoring, analyzing and reporting on surface movements, and a new ribbon interface in Sentry Office increases the visibility of functions. This allows scans to be easily transferred between Sentry and PointStudio and zones created in one application appear in the other, for easier analysis.

Itasca Adds IMASS

and More…

Itasca’s offices in Australia, Canada,

Chile, Sweden and the U.S. focus on

geomechanical and hydrogeological

stability for large open-pit mines. The

company’s 3DEC, FLAC, FLAC/Slope,

FLAC3D, PFC and UDEC software packages

can be used for stability analysis

applications in soil and rock. For slope

design applications, 3DEC discontinuum

and FLAC and FLAC3D continuum software

are the most widely used.

Patricio Gómez, general manager for Itasca Chile, said: “The main benefit from faster and easier implementation of 3D analyses lies in the improvement of the representativity and accuracy of the results obtained, which should help optimize designs while maintaining or improving safety. Also, in many cases, 2D analyses have been interpreted to provide conservative results, which in the current market conditions can impact the economic outcome of a project.”

Many open-pit slope stability problems are truly 3D and a series of 2D slices, while informative, cannot fully capture the nature of failure mechanisms. Accurately capturing the complexity of open-pit to underground mining transitions and also the behavior of movement along 3D joints/ faults out-of-the-plane can also be tricky. The Itasca Constitutive Model for Advanced Strain Softening (IMASS) has been developed to represent the rock mass response to excavation-induced stress changes.

Christian Cancino, geomechanics engineer, Itasca Minneapolis, explained: “IMASS is used in continuum models to represent the damage around slopes, caving processes, pillars, open stopes and other excavations. It does this by accounting for the progressive failure and disintegration of the rock mass from intact, jointed and/or veined rock to a disaggregated, bulked material. IMASS is now the default constitutive model for mining applications at Itasca due to its powerful features and ability to closely mimic the behavior of rock mass under complex stress paths.” Whereas the Hoek-Brown approach considers rock mass damage as an input (disturbance factor – D), rock mass damage (magnitude and 3D distribution) in IMASS emerges automatically from stress relaxation following excavation modeling. IMASS significantly improves capturing the actual stress-strain response in the slope rock mass, producing better calibration of the failure process (rate of movement, etc.).

“With IMASS, we can capture the stress path and better calibrate models to displacements measured by prism, ground-based slope radar, GPS, InSAR or other instruments,” Cancino added. The team is also working to improve modeling performance within their software packages. Most of the software is now multi-threaded (including FISH scripting), with enhanced algorithms, new workflows and methodologies that make it possible to increasingly build, solve and analyze more than 100 million model elements. Python scripting has also been added. This provides useful libraries for 3D interpolation, importing complex pore pressures, block models, etc.

Improvements have recently been made to Griddle meshing tools to better handle complex geologies, discontinuities and excavations, and more sophisticated DFN generation tools are available within FLAC3D and 3DEC as well as DFN.LAB (new DFN-based software for fractured rocks with genetic DFN generation along with simulation and analysis of connectivity, flow and transport). MINEDW is also an important tool for Itasca’s slope workflow in order to accurately predict ground water flow, pore pressures and depressurization in mine slopes. For bench-berm and inter-ramp stability probabilistic analysis, KATS provides rapid kinematic assessment of the behavior of many slope configurations and structures.

Looking to the Future

Itasca has been working on prioritizing

the implementation of message passing

interface (MPI) versions for its 3D software

for modeling on parallel computing

platforms. This technology will dramatically

change runtimes and allow mines

to solve even larger problems with better

accuracy. These developments are being

sponsored, in-part, by external companies

but will become commercial in the

short term.

Tools for transitional modeling are also a focus as more open pits move to underground mass mining methods, as are more support for cloud computing and better integration between Itasca software packages. The Itasca team expects utilization of machine learning and artificial intelligence in slope design and analysis to increase in the coming years. For example, incorporating ubiquitous, real-time instrumentation/sensor data via machine learning for automatic model calibration, surrogate modeling or anomaly detection.

Web/cloud-based tools (e.g., design charts, decision matrix) based on machine learning from numerical simulations will also provide the ability to run more models, faster, and move toward probability of failure calculations to better consider uncertainties of rock mass properties and conditions. “It’s likely that we’ll see more scripting to provide for customization and parameterization, enhanced visualization through virtual and augmented reality tools, and more integration between different software solutions and merging of software providers to provide end-to-end solutions,” added Jim Hazzard, software manager, Itasca Minneapolis.