The walls are coming down. The newest slope stability solutions offer greater integration, making them

The walls are coming down. The newest slope stability solutions offer greater integration, making them

easier to adopt

and deploy. Above, dewatering effects on highwall stability can be modelled in the new,

integrated GeoStudio Core.

(Photo: Seequent)

One obvious trend in the latest slope stability

solutions is improved integration.

The newest tech can now either easily integrate

or be integrated. Since integration

is a prerequisite for the digital mine, the

trend should, in theory, nudge more miners

in that direction.

Another quality the newer solutions

share is ease-of-use. Their operation is

described as intuitive, their interfaces as

friendly, and training as minimal.

Both trends suggest that, at least in

theory, future solutions will be easier and

less expensive to adopt. More mines will

be able to deploy more solutions that

immediately detect and, increasingly,

predict rock movement. Thus, most importantly,

they bode well for the future of

mine safety in general.

Integrated Solutions

Speed Alerts

Hexagon Mining and sister company IDS

GeoRadar announced upgrades to HxGN

MineProtect Collision Avoidance System

(CAS) and IBIS Guardian radar monitoring

software that allow the two to communicate

and drastically cut the time

between slope stability risk detection and

workforce awareness of it.

Guardian’s integration with CAS 4.6

means properly equipped office personnel,

equipment operators and mine site

pedestrians can receive near-real-time

equipment visualization and timely alerts

about hazardous areas and no-go zones.

The no-go zones are defined in Guardian,

which creates geofenced zones, hazard

maps and alarms. HxGN MineProtect

solutions, such as CAS’s in-cab display

and the wearable Personal Alert, deliver

the alarms and other specifications.

Hexagon Mining described the development

as an industry first. “Others have

point-to-point or radio-based processes,

but can’t really drive the information to

the whole fleet,” Marcos Bayuelo, product

portfolio manager, MineProtect, Hexagon

Mining, said. “We’ve reduced the time to

communication to the minimum and really

ensured that the people that require

the information get it as fast as possible.”

The upgrades to CAS and Guardian

launched in June 2020, and the field

testing that followed revealed some of the

capabilities offered through integration.

With the integrated solution, the process

of alerting a workforce to a slope stability

risk can involve only one person. IDS

GeoRadar slope monitoring radars detect

movement. That goes to Guardian, which

alerts the geotech crew. The geotech then

reviews and signs off on the alarms and

any no-go zone. “That person drills down

to understand the alarm, and confirms it

and the no-go zone,” Bayuelo said.

With only a click, and at the speed of

the mine’s network, the alarm and no-go

zone specs are distributed through CAS

and email. “The no-go zone is in near-real-

time transmitted,” he said.

“So, now, all the vehicles and the vehicle

drivers can see be alerted instantly

about the incoming hazard,” Bayuelo

said. “Now they have the capability to

visualize where they should not go. And

if somebody gets in this zone, then the

supervisor or mine manager will see that

somebody is in the no-go zone.”

Recent updates allow Hexagon’s HxGN Collision Avoidance System and IDS GeoRadar’s

Recent updates allow Hexagon’s HxGN Collision Avoidance System and IDS GeoRadar’s

IBIS Guardian to communicate

directly for speedy slope stability alerts and the rapid

creation of geofenced no-go zones. Above, an IDS GeoRadar unit

scans a shadowy distant

slope. (Photo: Hexagon Mining)

Geotechs can set Guardian to monitor

certain areas more critically than it does

for others. “You have different levels and

it is up to the mine as to what hazardous

area is transformed into a no-go zone,” he

said. “Within Guardian, you say, I want to

monitor here, here and here, because this

is a slope movement hazard. Once that

hazard reaches a level of criticality, then

the geotechs decide when this becomes a

no-go zone because the risk of collapse is

so high that nobody should be there.”

IBIS Guardian now assimilates data

from, among other sources, the CAS server,

Francesco Coppi, production manager,

interferometric radars, IDS GeoRadar,

said. It “can automatically import the

position of vehicles and working machineries and visualize them in real time on

the radar displacement maps,” he said.

“Highly accurate displacement data is

provided to monitoring specialists in

near-real time, as it happens, and using

an advanced automatic atmospheric correction

algorithm to avoid any mistake.”

The primary benefit offered by the integration

is speed. “What it does is it allows

you to really not require manual communication

between supervisors and the

control room,” Bayuelo said. “It enables

you to really create a workflow automatically

through the system integration.”

Without the integration, you are living

in 2019, he said. “Somebody in the

control room, or that is monitoring the

hazardous area, has to call somebody in

the mine that now needs to go somewhere

to block the area, which would transform

this process into a half hour or more.”

Another benefit is awareness of who is

in or near the no-go zone. “Which means

that nobody has to count,” Bayuelo said.

“Nobody has to be present, because technology

is the one that is present.”

The biggest dividend is increased safety,

Neville Judd, communications director,

Hexagon Mining, said. “It is important

because it is linking two ecosystems that

were previously unconnected,” he said.

“That separation potentially put people

at risk and now the two things are connected

and we’ve made that automatic,”

Judd said. “People

can now know, if

they are using the

system, that they

can depend on being

informed immediately

if they are

in danger, whereas

previously that

wasn’t the case.”

The development

should help prompt

customers who

have one of the two

software solutions

to upgrade it and

to adopt the other,

Bayuelo said. Upon

adoption, any training

required should be minimal and center

on workflow changes.

“The new information that will be presented

to them will be intuitive enough

for them to understand it,” Bayuelo said.

“There is not a huge change management

or training regimen required.”

The integration illustrates a couple

of the missions of Hexagon Mining and

parent company Hexagon AB. “We are

now building solutions that can interact

with each other, talk to each other, make

decisions with each other, and enhance

the overall sum of our solutions,” Bayuelo

said. “We don’t only offer the best solutions,

but the solutions themselves make

the business outcomes better, which is

the end goal of our company.”

Platform Uses Most Sensors

GroundProbe reported seeing strong demand

for the MonitorIQ platform. The

supplier’s chief operating officer, David

Noon, said because of its unique capabilities,

the aggregation software system is

destined to become the standard platform

for the majority of open-pit mines around

the world.

The platform can assimilate data from

more than 100 types of sensors, including

types made by competitors. “It offers

the largest number of sensors you can incorporate

into a system,” Noon said.

“We have not locked out any data

source from this platform,” he said. That

combined with robust processing analysis

creates “a very data-rich environment

for customers” to support confident decisions

on monitoring requirements.

GroundProbe’s flagship slope monitoring platform, MonitorIQ, offers a one-screen view

GroundProbe’s flagship slope monitoring platform, MonitorIQ, offers a one-screen view

of all the sensors, to include third-party sensors, in a mine, offering near-real-time

visibility

of all movements and deformations. (Photo: GroundProbe)

“It will allow the mine to do some

pretty incredible things, including looking

more at the data science around what

each sensor provides and how it compares

with other sensors,” he said.

The platform offers a single-dashboard

aggregation provides an overview of a

slope or tailings dam, the company said.

The development of MonitorIQ goes

back to 2004 when a customer reported

needing the ability to assimilate data from

multiple sources on a single platform. “It

was a brilliant idea back then, but challenging

to implement,” Noon said.

“It probably hasn’t been until the last

five years that this really has been able to be adopted because of expansion of IT in the

mining industry,” he said. Now it can come

standard with GroundProbe equipment and

eventually “will be installed across the entire

GroundProbe fleet for our customers.”

The system has a number of features

that all but ensure widespread adoption.

It runs safety critical software complete

with a programmable alert system, and it

offers an intuitive interface that facilitates

reporting and supports efficient workflows.

MonitorIQ runs the company’s SSR

Viewer software, which provides data

analysis capabilities to detect movement

and can be programmed to send alerts.

“We have two types of notifications,”

Noon said. “There are the alerts built

into the GroundProbe monitoring systems

through what we call an alarm center.”

They give a warning when movement is

detected by a GroundProbe system.

“And then in the MonitorIQ platform,

with all of the third-party sensors, you can

set thresholds or triggers on data and on

trend analyses,” thus predicting movement

and giving an early warning, he said.

The alarm center uses “a watchdog

system to watch the software so if it is

not functioning correctly, the user gets an

alert,” Noon said.

Designed to be easy and intuitive to

use, MonitorIQ offers a one-screen view

of all the sensors in a mine. “If you want

to see all the movements or deformations

measured by all these different types

of sensors, whether they are point measurements

or line measurements or area

measurements from different types of

GroundProbe sensors, or even third-party

sensors, you get to see that all on a single

display and see how they all tell a similar

story,” Noon said.

The capability helps streamline report

generation to vastly reduce the time involved.

“They can design a standard template

and then draw in the data sources

into the template; and then, when they run

the report, it automatically updates the report

based on the live data from the MonitorIQ

software,” Noon said. “It is meant

to be a workflow process to make it much

simpler to get the data to a form that can

be easily understood by the operators.”

The platform is designed to be a core

system in an integrated mine operation.

“It is a platform that the industry has

been talking about for a long time,” Noon

said. It is more than a product, he said.

“It is building in an ongoing support for

the life of the mine,” he added.

Recently, the supplier released a solution

that was developed with customer

input and meant to help miners move

toward increased digitization. SSR-Agilis

is a turnkey, rapid-deployment, vehicle-

mounted standalone monitoring system

that uses 3-D real aperture radar. It

is ideal for smaller operations that need a

highly mobile radar system, Noon said.

“The customer asked to put a radar that

is typically on a trailer on a vehicle to be

able to move it in close and focus it exactly

on a work area, protecting the crew working

directly underneath a slope,” Noon said.

SSR-Agilis measures submillimeter deformations,

and maintains that accuracy

even as range increases. It can sit anywhere

from 30 m to 1,400 m from the target.

GroundProbe’s SSR-Agilis is mounted on a light vehicle for easy relocation, and can sit anywhere

GroundProbe’s SSR-Agilis is mounted on a light vehicle for easy relocation, and can sit anywhere

from 30 m to 1,400

m from the target. It has an integrated camera, making it easier for users to

locate movement detected by radar.

(Photo: GroundProbe)

It is designed to be easy to use, and

to provide optimal visualization. “The customer

is able to see the wall with a camera

image, but also with the radar data overlaid

on to it or co-registered with it. When

they see the heat map of the radar image

moving, they can, with their eyes, directly

identify the location on the slope that is

moving,” Noon said. “GroundProbe is the only technology that provides a co-registered

visual image and radar deformation

image to help to make a very quick intuitive

decision when safety is on the line.”

One result is increased decision confi-

dence. “From a user’s perspective, that is

the most valuable,” he said.

The customer selects the model of

light vehicle, and GroundProbe takes it

from there. “We deliver the vehicle of

their preference with the equipment installed

on it out to the site,” Noon said.

The solution broadens the already

vast range of monitoring offerings from

GroundProbe. “The technology that sits

on this platform is common across all

those platforms so all the software, all the

support and all the benefits that we have

are common across all the platforms.”

SSR-Agilis, of course, can speak to

Monitor IQ. And both can be supported

by our area reps and remotely.

“We are able to give solutions or solve

problems or do repairs or maintenance to

make sure the equipment is running with

as much uptime as possible,” Noon said.

“The miners really appreciate the local

and remote support, especially in this

time of COVID restrictions.”

Modular Series Does

Double Duty

Reutech Mining reported the MSR Modular

series, known for versatility, offers

simultaneous critical and strategic monitoring

capabilities with submillimeter

precision, making it the most advanced

system of its kind on the planet.

The third-generation movement-andsurveying

radar system is designed to

operate in extreme conditions, and can

integrate with technologies from third parties,

such as Lecia GeoMos, Trimble 4D,

QuickSlope, SlideMinder and Rocscience.

Reutech Mining’s MSR Modular series models can be truck-mounted, can integrate other sensors and

Reutech Mining’s MSR Modular series models can be truck-mounted, can integrate other sensors and

third-party

solutions, and can operate in extreme environments. Above, a unit scans for submillimeter

movement at Landau

coal mine in Mpumalanga, South Africa. (Photo: Reutech Mining)

MSR Modular offers multiple mounting

options, including trailer mounted, fixed

installation or vehicle mounted. The operating

temperature range runs from -50°C

to 55°C. Units are equipped with an integrated

onboard weather station with advanced

atmospheric correction algorithms.

Models within the series are licensed

for operating at as close as 30 m to as far

out as 4,000 m. They can operate off-level

by as much a 15°.

MSR Modular is known for its modularity,

Reutech Mining said. “It provides

building blocks that consist of a radar

module, battery module, generator module and solar module,” Jan de Beer, executive

manager, Reutech Mining, said.

“This allows for custom solutions for

each requirement.”

The MSR is also known for reliability

and accuracy. “It offers operational availability

of more than 99%,” de Beer said.

“It can detect submillimeter movement

over long distances in harsh environments

and volatile atmospherics.”

Units are capable of simultaneous strategic

and critical monitoring. “A single

standalone system will alarm on movement

in critical areas while also doing wide-area

or strategic monitoring,” de Beer said.

When powered by MSR Connect, the

series “is the most cutting-edge geotechnical

monitoring solution available on the

market,” he said. “It is considered to be

the world’s most advanced slope stability

radar, improving safety and productivity

through accuracy and reliability.”

It can operate as a stand-alone system,

or “other products can be integrated

with the MSR to enhance your geotechnical

monitoring program,” de Beer said.

“The Multi Purpose Platform offers

a mounting platform for various sensors

and equipment,” he said. “Typical sensors

include the Slope Vision camera,

in pit alarm systems, personal alarming

devices, automatic weather stations and

Wi-Fi repeater stations.”

After-sales support includes a 24/7 call

center, on-site support, geotechnical support,

and advanced virtual remote support.

MSR Modular reflects the company

slogan: Safety and productivity through

accuracy and reliability, de Beer said.

“We listen to what our client’s needs

are and we assist in providing custom

solutions to problems,” he said. “Our

mission is to understand the mining environment

and to provide the industry with

world-class products.”

LIDAR Scanner Bridges Gap

Carlson Software showcased the Carlson

Scan2K, set to soon be co-released with

software. The laser scanner is equipped

with an integrated high-resolution camera,

inclinometers, a compass, a L1GNSS

receiver and weatherproof housing, and

is designed to “bridge the gap” between

small short-range sensors and large longrange

sensors, the company reported.

It is a “high-accuracy, LIDAR scanner

that is extremely easy to use and easy to

integrate into existing or new slope stability

monitoring solutions,” Bradley James

Husack, special project engineer, Carlson

Software, said. “The amount of training in

the use and setup of the Scan2K is very

minimal and very intuitive. That combined

with the lower cost of ownership

and enhanced operational capabilities,

the Scan2K is a great choice.”

The Scan2K is designed to fill the gap

The Scan2K is designed to fill the gap

between smaller

short-range scanners and

bigger long-range scanners.

Unlike other

LIDAR scanners, Scan2K can operate in

mines that use prisms in slope monitoring. (Photo:

Carlson Software)

The supplier adopted the LIDAR technology

last year and announced Scan2K

in early 2020. The solution exemplifies

how far LIDAR in general has evolved in

two decades, Husack said. “The Scan2K

can and does provide an effective and

economical solution that can help enhance

and help with stability monitoring.”

Company literature described the

scanner as “perfect for all applications,

with programmable data collection rates

that enable a range of up to 2,000 m.” It

has a range accuracy of 5 mm at 100 m

and a range resolution of 2 mm.

Features include “three range settings:

250 m, 750 m and 2,000 m with associated

pulse rates of 500 kHz, 200 kHz and

50 kHz, respectively,” Husack said. “For

each pulse at those data rates, the scanner

will record up to four returns, which is

extremely helpful for vegetation and dust

penetration and bare earth applications.”

The vertical view can be adjusted from

the maximum 120° to a narrow field, he

said. “This will allow the system to collect

data at the set data rates over a smaller

vertical field of view, which will allow

denser data point collection.”

The variable range, scan rates, and

vertical view allow for customized and detailed

scanning of areas of concern.

“The Scan2K will also work with survey

prisms that are in the scanner’s field of

view that might be mounted or positioned

on the target area slope that are being used

for other methods of monitoring,” Husack

said. “Why this is important is that other

LIDAR scanners will shut down if a prism

is detected or encountered in the scan as

a means to protect the optics of the scanner,”

he said. “The Scan2K was designed

in such a way that it will be protected and not shut down when it encounters these

prisms at typical monitoring ranges.”

The scanner can be mounted on a tripod,

vehicle or moving platform. It can be

wired for power and data or can be battery-

powered and wireless.

It can be controlled by an onboard

touch-screen color interface that remains

visible in direct sunlight or, remotely, by

a tablet or PC running ATLAScan Software,

a data management system for

scan projects.

ATLAScan offers target-free automatic

alignment, 3D meshing, automatic

line features extraction and monitoring.

Scan2K can be paired with Point Cloud

Software, which offers automation for

large data sets. The software can process

millions of data points and has the ability

to go from field scan to finished plat.

The scanner can also be controlled

by third-party slope stability monitoring

applications.

Aggressively priced, the Scan2K was

set for market release in H1 2020, but

was delayed to Q4 due to the lockdowns.

The introduction of “the most versatile

terrestrial laser scanner on the market”

now is a subtle flex by the supplier, Husack

said. “This shows the forward-thinking

and evolution of Carlson Software.”

Integrated Software

Optimizes Modelling

Seequent released GeoStudio Core,

which integrates the three most heavily

used programs in the GEOSLOPE suite

and offers comprehensive modelling of a

wide range of soil and rock behavior.

GeoStudio integrates SLOPE/W for

modeling slopes; SEEP/W for modeling

groundwater; and a reformulated SIGMA/

W, with a comprehensive material

model library and automated strength

reduction stability analysis, for modeling

rock and soil deformations.

The integration allows users to conduct

multiple analyses all within a single project

file, Seequent said. “Results from one

analysis can be used by another, or analyses

can be made to simultaneously model

stresses and groundwater flow,” said Paul

Grunau, president, GEOSLOPE, Seequent.

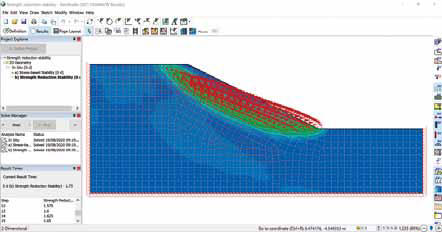

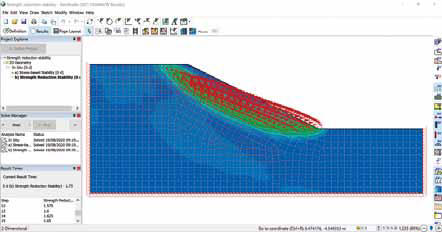

Geostudio Core integrates the three most popular GEOSLOPE programs. One is a new version of SIGMA/W,

Geostudio Core integrates the three most popular GEOSLOPE programs. One is a new version of SIGMA/W,

rock

deformation modelling software with a comprehensive material model library and automated strength

reduction

stability analysis. (Image: Seequent)

GeoStudio supports multiple geometries

within a single file, making it easy to compare

the effect of mine geometry on stability

and groundwater flow, he said. “It is also

multidimensional, meaning that 1D, 2D,

3D, Plan View and Axisymmetric are all contained

within a single project, with results

seamlessly shared between 3D groundwater

flow analyses and 2D stability analyses.”

Thus, it offers “the most rigorous

saturated-unsaturated groundwater flow

formulation in the geotechnical software

market,” Grunau said. GeoStudio is “the

only solution in the world offering the capability

of conducting both a General Limit

Equilibrium analysis and an automated

Strength Reduction stability analysis within

the same modelling environment.”

The integration empowers the user

to analyze the entire lifecycle of a mine,

from conception to closure. It can create a

digital twin of a mine for use in detecting

and resolving all potential failure mechanisms,

Grunau said. “It allows the engineer

to make confident decisions regarding

mine design,” he said.

GeoStudio Core is a Windows application

available by subscription. It can be

run as a standalone application. Or, when

used with Seequent’s Central, for cloudbased

file management, and Leapfrog, for

digital twin management and modelling,

it can offer a single source of truth in

change management.

As featured in Womp 2020 Vol 11 - www.womp-int.com