Figure 1—A typical setup of the

instrumentation on the operator seat

with the iPod placed ‘face down on

the seat …with the long axis of the

iPod perpendicular to the direction of

travel,’ as stated in the WBV v2.1

User Manual.

New, Inexpensive Methods Monitor Off-road Vibration Exposure

NIOSH researchers use an iPod app to assess whole-body vibration

By A.G. Mayton and Bryan Kim

Off-road mining equipment operating on rough surfaces under harsh conditions can produce WBV and mechanical-shock exposure to equipment operators. Until recently, the only methods to measure WBV were through expensive vibration measurement systems that may cost $4,000 to $50,000 or more and require significant technical expertise to analyze the data and arrive at meaningful results. University of Queensland researchers have investigated the use of a personal electronic device as a means for providing an uncomplicated and economical method to estimate WBV exposure in a mining environment. The whole-body vibration measurement application (WBV app) uses the built-in triaxial accelerometer of an iPod touch (model A1509, iOS version 9.3.5) to collect acceleration data and calculate frequency-weighted estimates of WBV exposure.

The National Institute for Occupational Safety and Health (NIOSH) recently conducted a study focusing on the measurement accuracy of the WBV app. The NIOSH field study involved data collection for 13 mobile machines (seven front-end wheel loaders and six haul trucks) operating at one sandstone mine and three limestone mines in central and southwestern Pennsylvania and northern Virginia. A major objective of the NIOSH research study was to assess the accuracy of the WBV app and determine if it can be a useful low-cost tool for monitoring WBV exposure on mobile mine and quarry equipment. Through field evaluations, the exposure levels measured with the WBV app collected with an iPod touch device were compared to exposure levels measured simultaneously with the Siemens/LMS SCADAS data recording system.

Approach

NIOSH researchers measured WBV in three directions, X

(fore-aft), Y (side-to-side), and Z (vertical) for operators of mobile

mining equipment as they performed their normal work.

NIOSH used a Siemens SCADAS–SCR05 16-channel data recorder

with 24-bit resolution as the reference, high-quality

precision system to which the iPod touch device running the

WBV app was compared. To measure WBV, NIOSH used a PCB

356B40 seat-pad accelerometer with the SCADAS recorder.

Collected data were stored in flash memory on a SD card. The

iPod touch device was placed under the front-most portion of

the circular seat pad according to the WBV app User Manual

(downloadable from University of Queensland website at

http://ergonomics.uq.edu.au/WBV/WBVpod/Index.html).

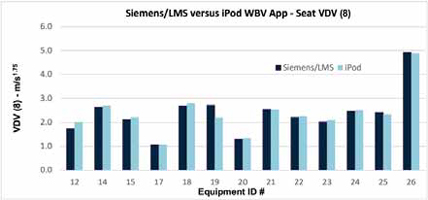

Vibration dose value (VDV) is a cumulative measure of vibration received by a person during the measurement period. This measure is more sensitive to peak levels and transients and is expressed in m/s1.75. The term VDV (8) represents levels normalized to an 8-hr shift.

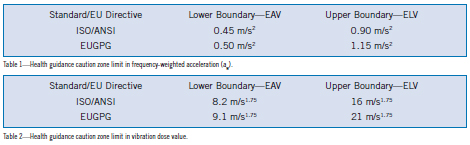

Health guidance caution zone (HGCZ) is a metric that uses vibration level and duration to evaluate when a subject is at risk of overexposure to WBV. The boundaries expressed in frequency-weighted acceleration and VDV are shown above for both the International Standards Organization/American National Standards Institute (ISO/ANSI) and European Union Good Practices Guide (EUGPG) for Directive 2002/44/EC. These boundaries represent the minimum health and safety requirements for exposure of workers to the risks arising from physical agents, such as vibrations. The exposure action value (EAV) is the level below which health effects have not been clearly documented. Those levels within the HGCZ indicate caution with respect to potential health risks. The exposure limit value (ELV) is the level above which health risks are likely. Tables 1 and 2 display the EAVs and ELVs in terms of aw and VDV.

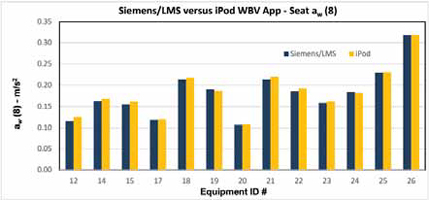

Absolute differences in percent for VDV (8) measures comparing the Siemens/ LMS and iPod measurement systems ranged from 0.3% to 18.8%. Eleven of the 13 instances showed percent differences of 4.4% or less. Moreover, the aw and VDV levels show strong Pearson correlation coefficients of 0.998 and 0.981, respectively. This statistic represents the strength of the relationship between two variables. Values of the Pearson correlation coefficient range between 0 (indicates no relationship) and 1 (indicates a perfect relationship).

This research showed that the iPod touch using the WBV app can serve as a low-cost tool to estimate operator WBV exposures on mobile mining equipment and demonstrates results similar to those obtained by Burgess-Limerick et al. In their 2016 ACARP project report, “Managing Whole-Body Vibration at Surface Coal Mines,” Burgess-Limerick and Lynas obtained 96 vertical measurements of acceleration using the app and a commercially available vibration measurement device, the Svantek SV 106. They concluded that the WBV app downloaded to an iPod touch provided a 95% confidence of ± 0.07 m/s2 for the vertical direction and their results were consistent with those they previously obtained using the app.

Alan Mayton is a mining engineer and Brian Kim is a mechanical engineer. Both work for the Pittsburgh Mining Research Division of National Institute for Occupational Safety and Health (NIOSH). Alan Mayton can be reached at: anm9@cdc.gov

Acknowledgements

The authors thank Robin Burgess-Limerick, Ph.D., of the

University of Queensland, Australia, Jonisha Pollard, M.S., and

Mahiyar Nasarwanji, Ph.D., for their support and contributions

to the field data collection protocol and data analysis in performing

this study.

Disclaimer

The findings and conclusions in this paper are those of the authors

and do not necessarily represent the official position of the

National Institute for Occupational Safety and Health, Centers

for Disease Control and Prevention. Mention of any company or

product does not constitute endorsement by the National Institute

for Occupational Safety and Health, Centers for Disease

Control and Prevention.