Figure 1—The burn cut in real life, the

relief holes are painted black and the

loaded holes are painted red.

Modern Underground Blasting Methods

What face round would work best and why?

By Anthony Konya, Dr. Calvin J. Konya and Dr. Paul Worsey

Combined with these problems, underground blasts can be difficult to monitor and evaluate due to tight spaces, dust during the blast preventing video, and the need to evacuate the immediate area with no clear line of sight to observe performance. This creates an environment in which most mines know that blasting can be improved in their underground operations, yet most are hesitant to change due to fears of the shot freezing, misfires and questions about how to achieve a proper design. Unlike with surface blasting, the explosives companies and shot service providers also offer limited assistance or knowledge in the underground blasting realm, leaving underground operations in the dark. It is for these reasons that most underground operations are operating decades behind the current technologies and incurring significant costs, both real and hidden, from their blasting operations.

For these reasons, the authors are working with Engineering & Mining Journal (E&MJ) to bring an article series to the readers to aid in the design and optimization of underground blasting practices. In this article, the major methods of underground blasting for face rounds will be discussed from an operational standpoint with the focus of helping mines choose which method of blasting would be most advantageous for their operation. In future articles, these patterns will be examined and methods for 21st century design will be discussed.

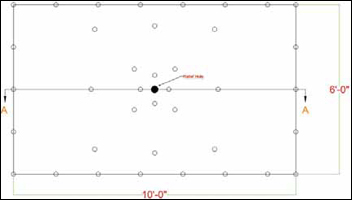

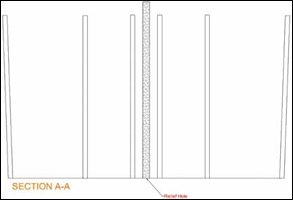

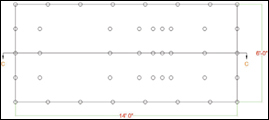

The Burn Cut

The burn cut is one of the older forms of

underground blasting, where a part of the

blast (the burn) of a shot is heavily loaded

with additional empty (relief) holes

with the goal of smashing (aka burn) and

pushing/blowing all the material in the

burn out to provide relief for subsequent

blastholes. The relief holes in the burn

cut provide a parallel relief for the holes

that are firing to break also, creating a

second plane of relief, however, these

are extremely small and can cause many

problems if a design is improper.

Burn cuts are perhaps the most complex methods of underground blasting and the design can be one of the difficult starting points due to the sheer number of possible designs. There are dozens of different forms of burn cuts that could all be tested at a site to determine which is more or less effective, however, this would span months to years of testing with frequent below standard performance from burn cuts that do not perform well. Because of this, most mines stick to the same burn cut that has been used for decades. However, the burn cut is the most important part of a burn cut round, as it will control the maximum face advance, susceptibility of the round to freeze3, and with improper burn cuts, a vibration increase of up to five times the original vibration levels for the rest of the round (production holes). The burn cut is commonly used in mining in places like the Nevada gold mines and Lake Erie salt mines, and other operations around the world.

In addition, burn cut rounds can produce very fine fragmentation and a well-placed muck pile depending on the location of the burn cut. The actual burn cut can be moved vertically and horizontally to change the cost, fragmentation, and throw of the material allowing an engineer or supervisor to modify the general layout of the burn cut to achieve a higher bucket fill factor or increase crusher throughput.

Additionally, burn cut rounds, in general, will have less boulders than other rounds due to the higher explosive loads and straight holes creating very similar back burdens on the round. This characteristic, along with the increased fragmentation and the ability to place material, makes burn rounds very popular in metal mining situations.

Disadvantages of a Burn Cut

While the burn cut has many advantages

such as control, placement, and minimization

of boulders, several disadvantages

also exist. The first major disadvantage is

the complexity in design and hookup. As

previously discussed, the burn cut can be

designed numerous ways just with borehole

placement. Combine this with extremely

critical timing of both the burn

and the production holes and a burn cut

can be a challenge to properly design

and hookup, especially with non-electric

blasting caps, which are very common

because of cheap cost and relative safety.

These deviations in the hole and at the collar are compounded if the same drill is being used to drill the relief holes. In general, relief holes need to be larger than the blasthole to provide adequate relief for material to move. This either requires multiple drills/drill bits or drilling multiple small holes together to simulate a large hole. For example, if a 4-in. hole was desired for the relief hole, either one 4-in. hole could be drilled, or four 2-in. holes could be drilled within inches of each other. Any deviation on these holes could significantly impact the performance of the burn cut.

Burn cuts also suffer from the close spacing causing flow of the rock and deformation of boreholes near each other. This deformation can cause a densification and deadpressing of the explosive, leading to misfires, freezing of the face, and poor face advance.

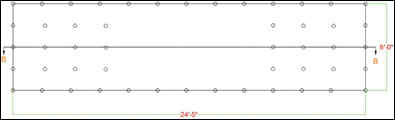

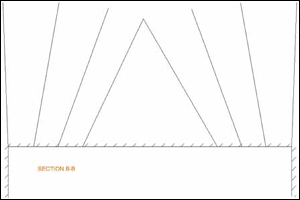

The V-cut

A V-cut is one of the most commonly

used blasting patterns in underground

aggregates due to its comparatively low

drilling and blasting costs. The typical

V-cut has the drift divided in half with the

first hole put on a large angle to break the

middle of the drift out. After these first

rows of holes, each row is angled slightly

less to allow for the V-cut to eventually

have holes that slightly look out along the

ribs. Because of the need for extra room

for the angled drill boom for the middle

V, larger rooms are generally required for

V-cuts. While V-cuts can be simple to design,

they can be difficult to accurately

drill due to the changing angles and accuracy

of drillers to adjust and measure

these angles. The V-cut is used in numerous

underground operations in the U.S.

for aggregates mining. It is also used

internationally, such as in underground

coal mining in Brazil without the use of

an undercut.

Advantages of a V-cut

The V-cut has numerous advantages over

other cuts, if the space is available for

them to function. The first of these advantages

is a reduction in cost due to less

overall drilling and lower explosive load.

A majority of holes have full burden and

spacing, with only the V holes having an

increased powder factor. One important

note, reducing total drilling does not

equal reduced total drilling time.

Another advantage of the V-cut is that the larger the width of the room, the larger the total face advance can be achieved, with the proper drilling equipment. This is an advantage over the burn cut that will reach a maximum depth due to the ability of the burn to eject. With the V-cut, as the width gets larger, the pattern can be designed to reach deeper and maintain the required angle for breakage and material ejection. In most cases, the depth of the V-cut is limited by the width of the room and ability of drilling equipment.

Disadvantages of a V-cut

While the V-cut has many advantages, it

also has numerous disadvantages. The

first that will be discussed is the limited

face advance. As previously stated, the

wider the drift the farther the maximum

possible face advance. However, this is

also a limit that is imposed on the V-cut

along with the maximum reach of the

drilling equipment. Because the V-cut requires

angled drilling, the drill reach is

not fully utilized and is generally around

80% of the total reach of the drill steel

thus a reduced maximum pull depth. In

addition, many drifts are not wide enough

that the V-cut will be able to reach farther

than a burn cut, even with proper

drilling equipment. For example, a burn

cut with a 15-ft face advance can generally

be achieved without a great deal of

complexity. However, a V-cut with a 15-ft

face advance would require a room over

35 ft wide and a drill steel that is 20 ft

long, which can be difficult to find underground.

In addition, this could create

extremely large boulders at the site.

The second major disadvantage of the V-cut is that large boulders can be produced from the center of the shot. These boulders are then either put aside and never processed (creating a hidden cost of lost material) or secondary blasting methods are used to break them (increasing cost). However, these can be eliminated by the use of baby Vs or buster holes. This will add additional cost and create additional difficulty in the drilling process. In addition to these large boulders, the throw of a V-cut will leave a scattered muckpile throughout the drift.

The third disadvantage of the V-cut is in the difficulty of drilling the round. Due to numerous angles, which are often poorly measured and rarely recorded, the driller must spend a significant amount of time attempting to get close to the correct angle. Additionally, the drill must set up in numerous places and in different positions to properly drill the pattern. This is also one reason the V-cut has difficulty being used in small rooms — the drill cannot set up far enough to the side to drill a large enough angle for the center V.

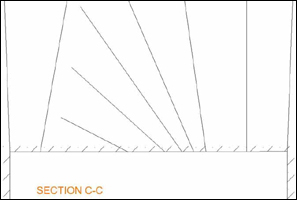

The Fan Cut

The fan cut is a less commonly used form

of angled drilling that can be used in

drifts that are smaller than a V-cut. However,

the fan cut still needs larger drifts

compared to a burn cut. A fan cut involves

angled drilling on one side of the face with

the goal of removing half of the face and

blasting the remainder into that opened

area. This is an effective method for blasting

in small- to medium-sized drifts where

V-cuts are not applicable; however, a price

lower than a burn cut is desired. This

technique is primarily used in aggregates

and is used for the first round of a cross

cut in room-and-pillar mining in metals or

hard rock mining environments, such as

in the Missouri Lead Belt, and is known in

some operations as “slashing.”

Advantages of a Fan Cut

The fan cut provides some advantages in

underground aggregates blasting when the

drift width is smaller than what is possible

with a V-cut. This can reduce the cost of

drilling and blasting when compared to a

burn cut by reducing the total number of

holes, however, this could reduce the total

face advance. In the end, an economic

analysis will need to be completed in order

to determine whether a shorter face

advance with less holes is more or less

economic than a longer face advance with

more holes. Production considerations

must be made with this type of cut.

Disadvantages of a Fan Cut

The major disadvantages of the fan cut

are that it can result in a higher cost than

a V-cut in larger rooms and the minimal

face advance compared to the burn cut in

smaller rooms. For these reasons, fan cuts

are selectively used in specific mining situations

where their use has proven more

economical than either the V-cut or the

burn cut. In the right conditions, the fan

cut can provide a cost-effective way to use

the advantages of a V-cut in a smaller drift.

Another disadvantage of a fan cut is that a straight face profile is rarely developed, with an arching face more commonly present due to the geometry of the blast. This causes blasting crews to have to “square up” or create a straight face after every few blasts. This can be a hidden cost that would result from the use of a fan cut.

The decision for choosing and optimizing any underground round requires an understanding of the processes and principles of operation with each of the underground rounds as well as a fullscale view of the mine-to-mill processes. The goals of the mine in relation to the desired fragmentation, desired condition of the muck pile, handling of boulders, drilling equipment, and other operational problems need to be identified to choose an optimal pattern to be used at any site.

After all these issues have been identified and costs associated with them, economics will then determine the optimal pattern. However, testing of any pattern being considered needs to be completed to ensure that rounds function as expected. In future articles of this series, the design for these rounds will be discussed.

Calvin Konya is the founder of Precision Blasting Services (PBS). Anthony Konya serves as project engineer for PBS and Dr. Paul Worsey is a mining professor and well-known explosives expert and researcher at the Missouri University of Science and Technology. www.idc-pbs.com