The cabless, autonomous PV-275CA, pictured above at a test and

The cabless, autonomous PV-275CA, pictured above at a test and

demonstration site, is tried, true and reflects the

company’s commitment

to Industry 4.0, Atlas Copco reports. ‘We believe strongly in automation

and particularly

what automation can contribute to a mine operation,’

Tyler Berens, product manager, automation, says. ‘This cabless

Pit Viper

not only shows our commitment to that but also is field-ready to go

autonomous.’

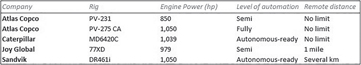

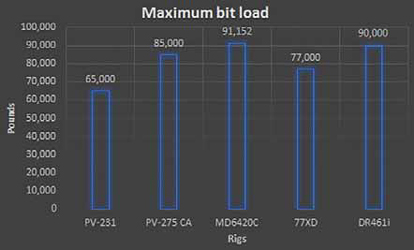

By the close of 2016, four of the majors

debuted new drill rigs. Three unveiled

new rotary blasthole drills at MINExpo.

All four now offer either semi- or full-autonomy

and machine data integration to

mine planning and management systems.

This means these days when one shops

for a blasthole rig, they are also shopping

for remote control and monitoring solutions.

The differences in the latest offerings

are found in the details.

Cabless Rig for Office Control

Atlas Copco displayed several advancements

and offerings at this fall’s convention

in Vegas, all of which represent

the company’s dedication to innovation

and calculated advancement toward fully

autonomous drilling, Matthew Inge,

product line manager, blasthole, said.

Most noteworthy are a new drill rig, an

upgraded cabless and fully autonomous

rig, and three autonomous systems software

packages for upgrading existing machines

and fleets.

Debuted at MINExpo, the Pit Viper

231 is the latest addition to the successful

PV-230 series, which is operating in

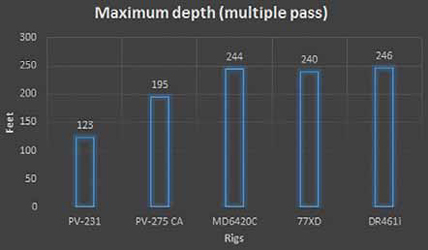

15 major mining markets. The single pass

offering builds on the PV-235 platform,

the company reported. It bolsters a 53-ft

(16.2-meter [m]) clean hole, single pass

tower capable of drilling a hole between

6.75 in. and 9.88 in. (171-250 millimeter

[mm]) in diameter.

Those specs should catch the eye of

miners, Inge said. “Previously much larger

drills were needed because of the tower

size to drill those holes in a single pass,”

he said. “What we’ve tried to do is create

that same single-pass depth but on

a frame and on a machine that is 30%

lighter than its predecessor and competitors.”

The benefits are numerous, he

said. “It improves the time spent drilling,

which is just value added for the blasthole

drilling process,” Inge said. “You’re

no longer changing drill rods. You don’t

have that inefficiency.”

Reduced weight translates to reduced

costs. “If you can give that same value in

terms of single-pass depth but at a lower

weight, then you should see the costs

to operate that machine go down,” Inge

said. The rig, like the others in the Pit Viper

series, is “technology capable” and a

“gateway” to greater automation, he said.

The rig is “an entry for most customers

to get in there and get their hands on it,

and feel it, and see things for themselves,

rather than just read about it on paper.”

The PV-231 is scheduled for prototype-

testing later this year, but has already

piqued the interest of several miners.

“We’re starting to gain interest with

customers to see the machine out in the

field,” Inge said. The company worked

with a number of gold miners to perfect

the drill and their processes deploying it.

The rig “suits most gold mines globally as

well as some copper and strip coal applications,”

he said.

Also unveiled in Vegas, but as a concept

design, the Pit Viper 275 CA, a fully

autonomous and cabless blasthole drill,

features the company’s proven CAN-BUS

Rig Control System (RCS), which enables

the miner to operate the drill from an office. “We can put that machine out in the

field today,” Inge said. “That is our confidence level in autonomous drilling.”

To maneuver it for maintenance, the

drill is equipped with a terminal with an

RCS display, controls, stool and table. The

location of the terminal wiring makes it

simple to select a cab or terminal without

sacrificing lead time, the company reported.

This enables a miner to remove the

cab, if needed. RCS components, such

as GPS radios, network hardware and the

Common Communication Interface data

platform are located in a lit ground-level

cabinet. The rig also features a boarding

safety system, a high precision GPS system,

spinning lasers for obstacle detection

and a personnel detection system.

The PV-275 can drill to depths of 195

ft (59.4 m), with hole diameter sizes at

6.75 to 10.63 in. (171 to 270 mm).

Key to enabling control from an office

at a distance of up to 1 kilometer (km)

from the site, Atlas Copco’s BenchREMOTE

system, empowered by the company’s

patented Autodrill and Auto Rod

Change programs, reportedly provides a

10% increase in utilization benefits. “An

operator can control one or more machines,”

Inge said. “What they are doing

is supervising or overseeing the process.

Rather than one machine per operator,

you could potentially have one operator

focus on two or three machines. We actually

are doing that in the field.”

Autonomous drilling benefits the miner

“through efficiency, productivity and

safety,” he said. “We try to start every

discussion around automation with the

problem statement. What problem is the

customer trying to solve? Sometimes it is

all three of those. But usually there is one

or two that really stick out in the customer’s

mind.”

Regarding productivity, often the

problem statement centers on a desire

for greater predictability. “Drilling is at

the beginning of the mining process,”

Inge said. To build plans, miners want to

know the rig’s availability. “They are going

to optimize their fleet, their trucks,

their shovels, their blasting, all of that

based on what the drill is able to do,” he

said. “If the drill goes down, that process

breaks. We have to make sure it is rugged

and reliable. It is that first gateway into

producing more.”

Thus far, the CA technology has proven

itself in field tests. “The mine with Atlas

Copco autonomous drills has seen a

30% increase in productivity,” Inge said.

“They’ve also seen an increase in bit life,

an increase in availability and utilization,

energy savings, and the drill that they

have is on the 271.” Last July, E&MJ reported

that BHP Billiton tested two autonomous

PV-271s at the Yandi mine for a total

of 15,000 hours.1 The miner reported

that the automated rigs were 16% faster

per hole, had 20% additional utilization,

and one-third extra drill capacity. As a

result, the company ordered autonomous

upgrade packages for 18 drill rigs for a

staged rollout to be completed this summer

at five iron ore mines in the Pilbara.

Atlas Copco provides training and service

to facilitate a swift transition from

on-rig to remote control, sometimes occurring

in as little as a week.

For its electric over hydraulic controlled

rotary blasthole rigs, Atlas Copco

showcased the RCS Lite at MINExpo.

For the DM30 II, DM45, DML, DM-75

and DM-M3 rigs, and offered as part of

three packages, the system supports

touch screen displays and cab-mounted

user interfaces, and gives operators data

needed to improve efficiency for higher

quality holes, the company reported. The

BASIC system package offering features

the AutoLevel functionality. The CONNECTED

system package includes that

and wireless connectivity through WLAN.

It features the SurfaceManager software

for managing and reporting drill performance.

For maintenance and monitoring,

it features the Desktop Viewer, providing

a remote read-only connection to

the rig for troubleshooting. The TOTAL

package features the aforementioned,

plus a high-precision GPS functionality.

The package enables miners to wirelessly

send drill patterns and receive data from

the drill, the company reported. A geofence

creation functionality is included.

The concept and technology developed for the MD6420C,

The concept and technology developed for the MD6420C,

pictured here, come from more than 20 years of field

experience working with predecessor models, reliable Cat

components and innovative new designs, Greg Scott,

application specialist, says. ‘The MD6420C’s smarts protect

the operator, the drill and also ensure that day-in and

day-out

that quality holes are drilled — so they can be charged,

blasted, and resulting fragmented material can

be loaded,

hauled and processed.’

The RCS offerings reflect the company’s

commitment to completing each

crucial stage of development on the path

to full automation, Inge said. “That’s why

you see our drills in the field drilling autonomously

today,” he said. “We’ve done

that due diligence. We’ve done that long

process so it is making sure our systems

are rugged enough so there is no weak

link in the process.”

Satellite Guidance Cuts Costs

Caterpillar showcased at MINExpo the

MD6420C Rotary Drill, which can drill

holes up to 311 mm (12.25 in.) in diameter

and down to 74.3 m (244 ft) deep,

the company reported. Designed for a long

service life and high production at the

lowest total cost, it features an application-

matched power train, advanced control

systems and an optional automation

system. “The MD6420C with computer

controls drives lower total cost of ownership

than a conventional drill,” Greg Scott,

application specialist, said. “Even drillers

that initially reject the technology, find the

machine offers them advantages in safety,

ergonomics and productivity that are just

unachievable with earlier models.”

The rig is mounted on a Cat excavator

undercarriage with three-point oscillating

suspension, which allows negotiation of

terrain without overworking the mainframe,

the company reported. It features

heavy-duty coolers and high efficiency

hydraulics that work together with the engine

and air compressor as a system to

deliver the optimal bit load, rotary torque

and speed plus bailing air for superior

penetration rates and cycle times. Angle

drilling capabilities come standard. “The

mast can be raised or lowered in less than

40 seconds, even with a fully loaded pipe

rack and full drill string,” the company

reported. All critical components, including

the four leveling-jack casings, the

mast pivot and the drill deck, are welded

to the mainframe.

Control features include a user-friendly

operator interface that provides machine

health data and diagnostic functionalities,

the company reported. “In

the early days the rigs would be fitted

with (on-off) type switches to drive basic

interlock systems to protect certain

functions and components on the machines,

which was very basic in nature

and limited by its general electrical layout

and hydraulics,” Scott said. “With

the development of CAN-BUS computer

controls we have been able to take many

more conditional inputs and align them

with advanced programming to make the

machine ‘smart’ in regard to overall operation

and performance.”

The optional automation system controls

each step in the drilling cycle to

simplify operation and improve accuracy.

Connectivity and data management system

Cat MineStar Terrain guides the operator

and facilitates hole placement and

drilling depth, while also reporting on productivity

and providing feedback on variation

of bench geology. Terrain uses satellite

guidance and accurate depth-sensing

to ensure that perfectly placed holes are

drilled at the exact depth and angle. The

system enables depth accuracy within 10

centimeters, the company reported. “The

programmable variables for auto drilling,

tramming and other functions on the

drill essentially tell the computer what

it’s range of operation will be, whereas

the programming will then modulate the

machine within those settings to achieve

the best possible production rates,” Scott

said. “These protective circuits and drill

assist functions act as a ‘force multiplier’

and propel the operator to a productivity

level many times higher than they

could achieve with old-school manual rigs

without the computerized tooling and programming

onboard.”

The system can also contribute to

mine safety. Cat Terrain prevents rigs from

drilling over bootlegs so redrills avoid undetonated

holes from prior benches. Further,

it will stop the rig from leaving an

area defined by a virtual boundary. The

use of digital blast plans keeps surveyors

away from working equipment and unsafe

areas. “Safety interlocks and conditional

monitoring have greatly increased the

number of protective layers on the drill

— all orchestrated by complex programming,

which constantly monitors and

feeds input to the control system,” Scott

said. “Any variation that falls outside of

recommended best practices and the programmable

variables that are fine tuned

for a specific site or application will effectively

lock-out or de-energize a subcircuit

of the drill (or the entire drill itself,

depending on severity of the condition).”

The company reported that a miner deploying

Terrain will see a 50% reduction

in lost-time incidents.

Unveiled at MINEXPO and pictured here, the 77xD’s boxer style helps with cycle time efficiencies, Matt Collins,

Unveiled at MINEXPO and pictured here, the 77xD’s boxer style helps with cycle time efficiencies, Matt Collins,

product

manager, drills, says. ‘We are finding the mast offers exceptional strength and stability, standing up to

high

levels of torsional loading,’ he says. ‘The design also includes a lightweight carriage with dual pinion

engagement

that allows the mast to hoist and lower with full string engaged and carriage positioned at the top of

the mast.’

Terrain reportedly provides a 5% improvement

in loader performance as a

result of more accurate drilling and therefore

more predictable blasting. Loaders

can more easily work the muck pile, improving

load cycle times, fill factors and

overall haulage fleet productivity, Cat reported. In the plant, uniform material size

facilitates crushing for optimum throughput

and lower energy costs.

The system, in general, boosts productivity

and cuts operating costs, the company

reported. Additionally, uniformity of

processes reduces component wear and

therefore slashes the cost of consumables.

Miners will see “less damage due to accidents

during manual operation, lower fuel-

burn, consistent operation and output,

better tooling life, and holes drilled to better

precision,” Scott said.

Bottom line is the rig empowers operators

to more easily meet metrics milestones,

he said. “Ground conditions and

formation will constantly change, cutting

tools will wear, plus ambient and climatic

conditions will fluctuate, but the push

to hit production targets will always remain

the same,” Scott said. “With the

MD6420C the driller has a backstop with the onboard computer controls ‘assisting’

the driller to meet those targets.”

3-D Grid Detects Obstacles

Joy Global introduced the P&H 77XD

blasthole drill at MINExpo. The rig, with

a bit range diameter of 7.88 to 10.63 in.

(200 to 270 mm), can be configured for

rotary or hammer, diesel or electric power,

and single-pass or multipass drilling, the

company reported. The rig is equipped

with features the company said can deliver

an up to 10% maintenance and repair

cost advantage, and an up to 5% availability

advantage. “This new machine offers

tremendous versatility with the ability

to vary in configuration from simple base

functionality to highly equipped options

with technological features that optimize

cycle times, increase ease of use and lower

operational costs,” said Matt Collins,

product manager, drills. For example, it

has a boxer style mast construction with a

simple bolt-on rack and pinion pulldown

design. It features automatic bit handling

and pipe handling functions.

Like the competition, the rig features

automated functions, and can be

remote-controlled and otherwise integrated

to a digital or satellite system-en hanced mine. It is compatible with Joy

Global’s new high-precision GPS teleremote

operation console and automation

solution, which features geo fencing,

auto-navigation, obstacle detection and

mitigation, and the Hawkeye 360 camera

system.

The rig is remote controlled from a

compact portable console with the same

interface available in the operator’s cab.

It is effective from a distance of up to a

mile via local site mesh or Wi-Fi. Safety

features include a physical lockout key,

SIL-3-rated E-stop and a 500-ms communications

watchdog.

Enabling the rig’s automated functions,

sensors and an array of beams

create a 3-D grid that calculates size

and distance and can differentiate

objects. The user defines the GPS

limits for boundaries when creating

geo-fencing.

Auto navigation, the company said,

provides high-accuracy and uniform

drilling processes, ensuring desired

fragmentation size, which can increase

production and reduce wear on equipment

and components. It factors x, y

and z axes when setting hole depth.

The function ensures holes are drilled

within 10 centimeters (cm) of the

planned pattern. Advanced auto drill

adjusts the rotary speed and feed rate

to maintain the optimal depth. Operators

can compensate and adjust spontaneously

when needed to situations

that affect cycle time performance to

keep the bit engaged.

Other innovations separate the rig

from its predecessors and the competition.

Its new boxer-style single rack-andpinion

mast offers the same amount of

retract force as pulldown to aid the operator

in the case of getting stuck in tricky

material, or even hole collapse, Collins

said. “The user will not experience any

potential chain slippage, but rather operate

under constant load.”

While it has been proven to increase

efficiency, the rig also reflects Joy’s “safety-

driven core philosophy,” Collins said.

The rig’s auto bit changer function is one

example. “This was designed to allow for

the highest levels of safety with tasks that

are typically manually intensive: lifting

and threading bits,” he said. “The auto

bit changer allows the operator to simply

touch a button to exchange a used bit with

a new bit in less than 10 minutes — without

leaving the cab or, if operating the machine

in autonomous mode, without boarding

the machine. This revolutionary feature

will allow more time in-the-hole drilling.”

Similarly, the one-touch Auto Pipe

Changer function automatically exchanges

or adds drill pipe into the drill string.

“Typically, this would be a process-intensive

procedure that can introduce challenges

with cross threading,” Collins said.

The goal here is to offer efficiencies with

consumable management, leading to longer

component life and easier operation

through automation.”

Last year, Joy told E&MJ it had field

tested units at North American copper

and iron ore operations.

1 Controller, 3 Drills

Sandvik announced at MINExpo its AutoMine

Surface Drilling automation solution

system had been field-proven on the

DR461i rotary blasthole drill. The “system

improves machine performance and

efficiency by offering automated features

that enhance operator comfort and capability,”

Tab Siegrist, global product line

manager, surface drilling, said. “AutoMine

provides reduced cost, improved safety

and improved consistency to the high

performance of the DR461i.”

The rig drills an 8.5- to 12.25-in.-diameter

hole (216-311 mm) with a maximum

single-pass depth of 102 ft (31 m).

The maximum multipass depth is 246

ft (75 m). It is reportedly an evolutionary successor to the proven DR460, the

company said. “The DR461i features

class-leading rotary torque and feed system

power enabling improved drilling performance,”

Siegrist said.

The rig is equipped with a CAN-BUScontrolled

hydraulic system, enabling

monitoring for timely preventative maintenance.

Pipes can be handled from

within the cab, meaning without manual

intervention, by the hydraulic breakout

wrench. The cab features touchscreens,

armrests, angled windows and a safari-

style roof, the company reported. “The

cab and controls are ergonomic and efficient, offering greater comfort for an onboard

operator,” Siegrist said.

One selling point, the company said, is

wider, 360° walkways for drill access during

routine maintenance. A hydraulic main access

stairway comes optional and will give a

parallel step onto and off the drill.

The DR461i, pictured above, has class-leading rotary torque and feed

The DR461i, pictured above, has class-leading rotary torque and feed

system power, Tab Siegrist, global product

line manager, surface drilling,

says. ‘The i series control system offers improved efficiency with advanced

diagnostics to give the customer faster troubleshooting for shorter repair

times,’ he said. ‘The control platform is

designed for integration with the

Sandvik Automation Offering.’

The DR461i can be operated remotely

by a station installed in a van, a fixed control

center, or on a portable self-powered

trailer. “The AutoMine has a superior teleremote

station, available as a skid or trailer

mount, that is large enough for multiperson

simultaneous training,” Siegrist said.

The system communicates via line-of-sight,

direct to the drill or via the mine communication

network, the company reported. Up

to three drills can be managed per station.

“This further enhances machine efficiency

by removing the operator from the distractions

of the environment on the machine,”

Siegrist said. “Further, with the capacity

to operate three drills from one teleremote

station, efficiency of the drilling operation

is greatly improved.”

The GPS-based 3-D navigation system

ensures drilling accuracy, both for location

and depth, within 5 cm. Drilling data

is streamed to the command center in real

time, for use in downstream processes.

Coming standard with the latest versions

of autodrill and auto level, AutoMine facilitates

consistent control of parameters,

improving results and reducing wear on

drill feed and rotation systems. “The system

collects production data to allow for

better decision-making based on current

drilling conditions and allows for intelligent

blast loading by generating drilled

hole strata information from the advanced

‘Measure While Drilling’, MWD algorithms,”

Siegrist said. “The ‘Opti-Mine’

information management server collects

all relevant drilling data for improved drill

and blast results delivering the right fragmentation

to optimize the loading, hauling

and crushing.” In general, the system

improves the autonomous capabilities of

the DR461i and enables less-experienced

operators to achieve more predictable results,

the company reported.

Thus far, deployment of the technology

has fruited tangible gains for a miner,

who, as a result, plans to expand its fleet,

Siegrist said. “Sandvik has two DR461i

units in operation at a New Gold site in

Ontario where we have shown the ability

to improve the drilling performance, increasing

the total holes per shift with teleremote

operation,” he said. “The future

plan, once they have a third drill on site,

is to further improve the efficiency of the

drilling operation by utilizing teleremote

fleet, where one operator can control up

to three machines.”

Pairing AutoMine with the rig practically

ensures cost savings, efficiency and

operator empowerment, Siegrist said. “AutoMine

provides reduced cost, improved

safety and improved consistency to the

high performance of the DR461i.” The

combo presents a snapshot of future offerings.

“The evolution is occurring with the

incremental ‘i’ series models coming in the

next few years utilizing the SICA control

platform that is compatible with today’s

and tomorrow’s advancements. Enhanced

troubleshooting reduces repair time, thus

reducing costs. The latest release of our

easy-to-operate controls improves operator

comfort. Larger displays and advanced

lighting reduce nighttime visual fatigue,”

he said. “Sandvik’s next-generation autonomous

drills are just around the corner.”

An Attractive Exploratory Alternative: Sonic Drilling

Lower gold prices forced Ajax Mining

to look more closely at efficiency improvements

at its operation in Alaska.

“By updating our machinery and optimizing

our processes, we increased

production and decreased costs,” said

Kim Ferguson, owner, Ajax Mining.

“Ajax Mining’s success ultimately depends

on reliable and accurate geological

data. This enables predictable

and environmentally conscious production

where only viable deposits are disturbed

and processed.”

Like Ajax, many mining contractors

are looking for ways to increase productivity

and decrease costs. As mining

markets improve, the temptation to rush

through processes, such as exploratory

drilling, pre-expansion investigations and

thorough planning for new tailings storage

facilities (TSFs) will likely increase.

Regardless of the specific application,

whether it is the initial investigative work

or monitoring the situation after the fact,

sonic drilling could be an effective, efficient and safe option.

The crawler-mounted TSi 150C Sonic Drill Rig can drill up to 1,000 feet

The crawler-mounted TSi 150C Sonic Drill Rig can drill up to 1,000 feet

depending upon the lithology and casing

design.

The crawler-mounted TSi 150C Sonic

Drill Rig can drill up to 1,000 ft depending

upon the lithology and casing design.

The vibration of the drill string liquefies

the surrounding soil matrix reducing friction

and resistance. When rock or other

hard layers are encountered, the sonic energy

pulverizes the outer edge of the bore

while preserving a solid core for accurate

mineral analysis.

Sonic drill rigs usually can drill three

to five times and sometimes 10 times

faster than conventional rigs. This translates

to less time on site, more production

and fewer mobilizations to the field.

These units are uniquely suited for

exploratory work because it can create in

situ core samples for analysis. The precision

nature of the drilling and the ease

with which the drill string passes through

the substrate helps ensure the core sample

will be preserved. Additionally, because

sonic rigs can drill straight with

little or no deviation, the location of the

ore deposits is accurately determined.

A Sonic Drill Rig can reduce investigative

derived waste (IDW) by as much as

80% in comparison to more conventional

drilling methods. Along with the obvious

benefit of minimizing overall impact on a

site’s surrounding environment, reduced

IDW also translates into cost and time

savings, which can be differentiators on

a project.

While it is an attractive alternative for

core retrieval and exploratory drilling, it

can also be used for angle drilling and

can shift to split spoons, Shelby tubes,

and/or rock coring as the site conditions

and project objectives warrant.

The TSi 150C specifically offers the

benefit of a track mounting, so areas that

may be difficult for other types of drill rigs

can be accessed with significantly more

ease. And, it can drill a completely straight

borehole, according to the manufacturer.

Ajax is one company that will be turning

to sonic technology from Terra Sonic

International in 2017. “We have been

considering alternative drills for several

years,” Ferguson noted. “The sample

quality and ability to quickly drill a

wide variety of materials i.e., permafrost,

thawed and water saturated gravels makes

sonic drilling well-suited to our projects.

After considering multiple manufacturers,

Terra Sonic was our final choice due

to their excellent customer support and

knowledgeable staff. We were able to tour

their factory and were impressed with the

quality of the build and work that went

into each rig. We are eager to take delivery

of our new rig and are confident it will

help strengthen our exploration process

and consequently improve our overall

success.” Ajax is investing in a TSi 150C

Sonic Drill Rig

Assessing TSFs

While sonic drilling can help companies

like Ajax save money and time, it is also

ideal for the assessment of mining sites

for both safety and profitability. Over

the last few years, the failure of mine

tailings dams has become an all-toocommon

occurrence and has caused a enrenewed

focus on the design and construction

of these facilities. Mine owners

and operators are assessing the stability

of their existing impoundments. In addition,

owners are realizing some impoundments

contain tailings that, with

current technology, can be reprocessed

to produce valuable material.

Sonic drilling can assist during the

planning and design stages of TSFs.

Rapid exploratory drilling can help the

planners understand better the area in

which the impoundment is planned. Part

of this process might include the installation

of inclinometers so that it is clear

how material will flow in the area. These

rigs can also help with the installation of

monitoring wells so that the area can be

evaluated from a baseline to help ensure

no hazardous wastes are seeping into surrounding

groundwater tables. In-situ core

samples can show geologists the different

features of the substrate so that the

tailings facility can be placed in an ideal,

targeted area.

Once the TSF has been constructed,

sonic rigs can help with the installation

of piezometers for additional monitoring.

The ability of Sonic Drill Rigs to secure

perfect, continuous core samples means

that geologists and environmental experts

can regularly implement soil and water

sampling to make sure the structures are

sound and all hazardous materials are being

secured properly.

As featured in Womp 2017 Vol 03 - www.womp-int.com