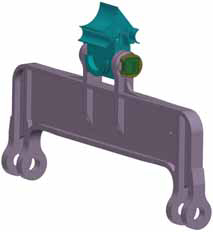

Dipper Payload-sensing System Gives ‘High Fidelity’ Measurements

The system provides measurements, not approximations, Charles Constancon, director of BMT WBM Canada, said. “Unlike other payload monitoring systems, which are based on electrical parameter or structural model estimation techniques to approximate the payload, the PULSETerraMetrixRS system deploys a smart loadcell sensing device, directly measuring the inertial and dynamic loads applied to the dipper and the payload. As a result, high fidelity payload measurement is maintained, even under severe dynamic loading conditions.”

Automatic dipper carry back measurement

and compensation supports

real-time differential payload calculation,

which is crucial for operations where the

material can often stick to the dipper, for

instance in the Canadian oil sands, the

company reported. Productivity improvements

of 8%-15% have been proven after

deployment of the PTMRS system, which

is supported by comprehensive database analytics and automatically generated

SQL Server email reporting.

www.pulseterrametrix.com