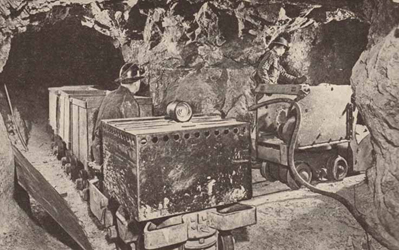

Train on main line waiting to be side-loaded by mucking machine from draw-point crosscut under

sublevel stope.

Miners Make Significant Productivity

Gains During WWII

Developments during the 1940s usher in a new era of mechanization and labor issues

By Steve Fiscor, Editor-in-Chief

World War II ended in 1945. There was a peacetime lull taking place as the world took stock of what had occurred. From a mining perspective, the effort to satisfy wartime consumption of natural resource culminated in another wave of mechanization. Many of the mines and mills in Europe and Africa were destroyed as the Nazis retreated. Government-instituted controls on prices and labor were being lifted. Knowing the past cyclic nature of the business, but not knowing what lies ahead, the industry was gripped with anxious anticipation.

“To summarize the favorable factors, in 1946 the price controls and other Government restraints which caused widespread dissatisfaction and inconvenience during the war were virtually wiped off the board,” wrote E&MJ Editor Evan Just. “The industry enjoys free markets, almost unbelievable demands for most of its output, unprecedented high prices for peacetime, and substantial alleviation of its labor shortages. The excess-profits tax is gone, and the outlook is for further tax reductions. Labor leaders know that the era of their sacrosanctity is passed and that they are due to be saddled with responsibilities commensurate with their power and privileges. Workers are realizing that the only sound way to improve their lot is through cooperation toward greater productivity.” His foresight about labor’s sacred position ending was spot on.

In 1947, the U.S. Congress would enact the Taft-Hartley Act and override President Truman’s veto. When WWII ended, roughly 25% of the U.S. workforce was unionized and their promise not to strike to support the war effort had expired. One labor leader, John L. Lewis, who headed the United Mine Workers of America (UMWA), which represented the nation’s coal miners, broke that promise. As a response to the rising union efforts and Cold War hostilities, Taft-Hartley was viewed as a response by business to thwart the post-WW II labor movement. Union propaganda often referred it as the Slave Labor Act. The Taft–Hartley Act was seen as a means of demobilizing organized labor by limiting its ability to strike and by prohibiting communists from their leadership. McGraw-Hill used the pages of E&MJ and its other trade journals as bully-pulpits to advise business owners, executives, and managers how to handle the situation and protect their business as well as national interests.

While the war was being fought, the mines and mills along with every other aspect of industry suffered from massive manpower shortages. To overcome these issues, productivity improved through the use of technology. The mechanization process that was well under way began to accelerate. Just as it does today, E&MJ was sharing a wealth of information in addition to offering news and opinions.

Mining Technology Progresses

Labor shortages, plus absenteeism, and

slow delivery of supplies hampered mining

companies and mining equipment

manufacturers. This situation pushes

mine operators toward a greater degree of

mechanization, such as automatic-feed

drills, jumbos and the more liberal use of

mucking machines. The automatic-feed

feature can drill 40% to 50% more ore

per man. The technology saves time and

labor by speeding up the work of backing

out of a hole.

More diesel-powered, rubber-tired equipment began to appear underground. Some mines were experimenting with diesel-powered locomotives on the haulage levels. “Bureau of Mines officials, once strongly opposed to employing internal-combustion engines underground, have reversed their opinion as to diesel locomotives, after long study of the reportedly successful use of them in underground mines in Europe,” E&MJ reported. “Putting aside a long-standing prejudice, metal-mine operators are investigating the possibilities it offers of cutting haulage costs.”

Whatever the possibilities that the diesel locomotive may offer for the future, electric haulage continued to dominate the mining picture. The relative position of the trolley and battery types was much the same as it had been for years. Both have their proper fields, the trolley locomotive having been considered best where hauls were long and large capacity was wanted. The battery locomotive was very flexible up to the limit of its ampere-hour capacity. It also made the overhead wire unnecessary.

The miners were drifting with diamond drills and tungsten-carbide bits were improving regular rock drilling operations. “The long-continued evolution of drilling practice has stepped up to a revolutionary pace as certain groups in the mining industry have become aware of the truly marvelous rock-penetrating ability of drills tipped with tungsten carbide,” E&MJ reported. “The new development comes at a time when it will do much good in offsetting the sharp increase in labor costs.”

Belt conveyors, which were traditionally found only on the surface, were being used more underground. “Belt conveyors, having demonstrated their usefulness and economy in open-pit work, not only in the bottom, but where long centers and high lifts are involved in transporting material up and out of the pit, offer interesting possibilities for longer distances underground where a drift can be readily maintained and the ore and rock delivered without damaging the belt,” E&MJ reported. “Recent improvement in belt construction now permits much longer uninterrupted distances between pulley centers with a corresponding decrease in the number of transfer points and motor drives required.”

“So far as we know, the war’s sole direct contribution to mining practice thus far has been the shaped charge,” E&MJ reported. “Learning of the so-called Monroe effect, and having available a returned veteran who had had much experience with the use of shaped charges in demolition work in the Pacific theatre, a Utah company, National Tunnel & Mines Co., set about experimenting with explosives in homemade containers designed to produce and utilize the jet effect that had worked such wonders in destroying tanks.” The results of this test work, applied in secondary blasting and in opening plugged raises, were described in detail.

Mechanized loaders and mucking machines were improving productivity in driving shafts and the development headings. “Never has mucking been so highly mechanized as today,” E&MJ reported. “In all but the smallest mines hand-shoveling is disappearing rapidly. Manpower shortages have promoted the wider and more efficient used of scraping and of mechanical loaders.” Slushing systems, using tuggers and scrapers, were becoming more prevalent. E&MJ reported that scrapers are growing in size, limited by timber clearances and shaft diameters.

Advances in Ore Dressing

“Not only are processes new to milling

being applied in the field, but new and

less expensive ways are sought of running

the old processes,” E&MJ reported. “The

combination of high wages and other

costs with decreasing grades of ore renders

some form of cost-cutting essential.”

Large crushers were being installed with the goal of crushing the day’s grist in one shift. Flowsheets were simplified wherever possible, and larger units (in gravity concentration for example) and simpler circuits have been applied to cut down on individual attention by operators. To make operation easier, mills have been designed with all units on a single level or on two levels. Automatic controls were increasingly applied to make mill operation easier.

Taft-Hartley and the Miner

Immediately after Taft Hartley is enacted

in 1947, E&MJ began to offer readers

ideas as to how to comply and encouraging

them to be truthful with workers. “A

mining employer, alert to help counteract

misleading union propaganda about the

Taft-Hartley Act, will be serving his own

and the industry’s interests if he takes

time to plan a careful, long-term campaign

of employee education based on his

company’s special needs,” E&MJ offered.

“There is little doubt but that the first round in the fight over the Taft-Hartley Act has gone to the unions. At swords’ points on almost every other issue, all union leaders are united in one determined effort to smash this law, and their first weapon, propaganda, has been most effective. Their success is evinced in the attitude of workers, as shown by recent opinion surveys. Although they approve in large majority of all but one of the Taft-Hartley Act’s major provisions, workers disapprove of the Act itself. This is almost certainly the result of the ‘Slave Labor Act’ propaganda to which they have been subjected by union leaders.”

E&MJ calls for an educational campaign by the management of mining companies. The editors warned that the employers who have tried it testify that the job is not easy and that a one-shot attempt to give employees the truth “may be not only ineffective but even damaging.”

The overwhelming majority of Americans wanted the act, E&MJ explained, “and it is a fair law. These are facts that can be proven to reasonable men. But employees may be in an unreasonable frame of mind, and any campaign of education, however truthful it may be, is a flat, dismal failure if the men refuse to believe it. Management needs to tell the truth, and it needs to be believed.”

Intelligent planning for employee education will be required, E&MJ explained. “One thing in management’s favor is that time, during this lull, is on management’s side; particularly in the mining industry.”

When the Taft-Hartley Act became law, the leaders of the Mine, Mill and Smelter Works (MMSW) knew they must forego use of the National Labor Relations Board (NLRB). “To use the NLRB, they would have to swear that they were neither communists nor sympathetic to communism. After the CIO [Congress of Industrial Organizations] report had named names and dates on their communistic activity, the jig was up,” E&MJ reported. “The MMSW leaders simply couldn’t sign non-communist affidavits, without facing serious penalties.”

The MMSW leaders promptly denounced the NLRB as a new agent of Wall Street and refused to have anything further to do with it. It is also at least part of the reason why the MMSW high command insisted on deleting no strike clauses from all new contracts. “The union doesn’t want to be sued for wildcat breaking of such clauses, but it also may need the strike weapon to get the recognition it can no longer get by peaceful, NLRB-controlled elections,” E&MJ reported. “The MMSW must now rely on plain collective bargaining to get what the Government used to give it. Thus they establish, in a roundabout way, the return to collective bargaining.”