Kraft Arena Skellefteå

Skellefteå Hosts Euro Mine Expo 2016

Preparations are under way in northern Sweden for Scandinavia’s largest mining

conference and exhibition

By Steve Fiscor, Editor-in-Chief

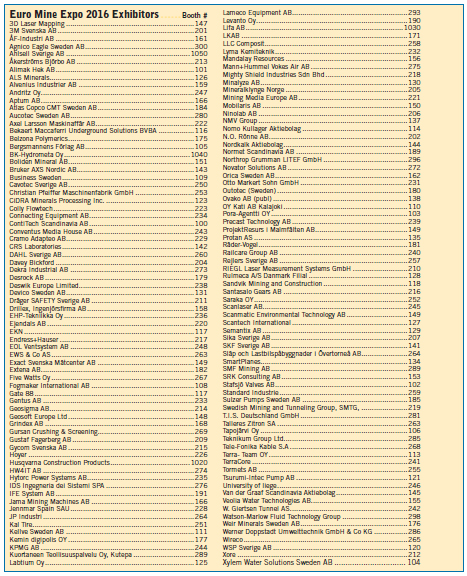

While the business climate has changed in the last two years, Euro Mine Expo’s organizers said that companies are quite eager to participate. In 2014, more than 2,000 people from 36 countries attended. Euro Mine Expo 2016 has four gold sponsors: Atlas Copco, Boliden, Outotec and Mandalay Resources, and an exhibition with a little less than 150 companies. “We have a few open stands in the copper hall and the outdoor area,” said Jaana Tengman, project manager for Nolia. “Unlike the others that may have wanted to test the waters in the past, these companies are committed to the mining business in northern Sweden. They realize that this is a soft period and, when the business turns, they want to have a foot in the door.” Nolia is the biggest organizer of fairs in northern Sweden. The company also undertakes national and international consulting assignments, bringing together more than 200,000 people every year to exchange experience and to network.

Euro Mine Expo also offers a technical program with presentations geared toward professionals in mining and mineral processing. With the help of Luleå University of Technology (LTU), which is situated just to the north, along with its gold sponsors and other organizers, Nolia has developed a program with information for everyone. The formal program consists of three sessions: Innovations & Business Development, Sustainability in Action, and a Market Outlook. It begins on Tuesday afternoon with sessions on Wednesday morning and Thursday morning. Other sessions and meetings have been organized peripherally and the details of those will be posted at www.eurominexpo.com.

Organized a Bit Different

In Skellefteå, hockey is one thing that

is more important than mining. Euro

Mine Expo takes place at the Kraft

Arena. Named after Skellefteå Kraft, a

Swedish power company, the 6,000-seat

venue is home to the Swedish Hockey

League’s Skellefteå AIK, as well as Division

1’s SK Lejon. Readers should note

the scoreboard above the show floor in

the photo below.

The opening session, Innovation & Business Development, offers a technical perspective. The fi rst speaker, May Hermanus with the Council for Scientifi c and Industrial Research (CSIR) South Africa, will explore future technology needs.

The second presentation by Pär Johansson and Maria Magdalena Holmgren will discuss the KIC (pronounced kick) program and other European Union (EU) Initiatives. The European Institute of Innovation and Technology (EIT), which aims to enhance Europe’s ability to adapt quickly to the fast pace of development, created a KIC (Knowledge and Innovation Community) for Raw Materials (http://eit. europa.eu). “The goal of this KIC is to boost innovation as far as the raw materials challenges in Europe,” said Österlund. “Several KICs have already been established for energy, health, etc.”

“During these periods of low metal prices is when the mining business usually sees some of its greatest innovations,” Österlund said. He cited the Boliden presentation on 5G as an example. During that presentation, Peter Burman, program manager mine automation, Boliden, will discuss the fifth generation of wireless technology.

The second session will delve into several aspects of sustainability. Referring to Karl-Erik Rånman’s presentation, The Fossil Free Mine, Österlund explained there is a big push in this region to distance themselves from carbon emissions. “For the mines of course, this means replacing diesel-powered equipment with biofuel or electrically powered equipment and using electricity generated from an emissions- free power plant,” he said. Following Rånman’s presentation, two LTU researchers will discuss a path toward sustainability. On the fi nal day, presenters will turn their attention toward the markets and offer delegates thoughts as to where it is heading.

This year the exposition side of the trade fair has been reduced from three halls to two. “This year, we have two crowded halls and the outdoor area,” Tengman said. “Using three halls in 2014 created some challenges with the social events. This year, the conference and the restaurant will occupy the iron hall with the main exhibition in the arena, the copper hall and the outdoor area.”

E&MJ reached out to many exhibitors and asked what they were planning to showcase at Euro Mine Expo 2016. What follows is small sampling of the technologies and services delegates can expect to see.

Solutions to Increase Processing Capacities

Outotec will demo solutions that mining

companies could use to tackle current

challenges such as depleting ore grades,

increasing effi ciencies and fi nding affordable

solutions to increase capacity.

The highlights will be the new cPlant

Flotation concept and sensor-based ore

sorting.

For flotation processes, Outotec has launched a modular cPlant Flotation concept. The plant is based on pre-fabricated and functionally tested modules inside container-sized steel frames that can be easily transported and installed, and quickly connected to the process. In the core of the plant is Outotec’s proven fl otation technology with FloatForce mixing mechanism and other Outotec TankCell features.

As most of the installation and test work is done at Outotec’s workshop, the plant requires less labor and lower capital investment than a conventional fl otation plant. The plant’s modular construction makes it economical to move to a new site once the ore deposit at the old site is processed.

The One-man Hammer

Fast and accurate grade control is the key

to an effective mineral extraction process

and ultimately to mining productivity and

profi tability. That’s why Atlas Copco Secoroc

extended the RC hammer range with

COP RC45—the smallest, lightest and

fastest reverse circulation hammer ever.

The 120-mm (4.5 in.) COP RC45 reverse circulation hammer features a revolutionary new design. Since it is 40% shorter than the nearest competitor and more than 30% lighter than most hammers doing the same job, one man can easily handle the hammer by himself.

Like the RC 50, the COP RC45 hammer features Atlas Copco Secoroc’s tube retention system. This design allows fast and easy service, and tubes are quickly replaced without disassembling the hammer. The result is less time servicing the hammer and more time sampling.

LED Headlights

Designed to be effi cient and robust, Finnish

work light producer Nordic Lights believes

its LED combination headlight will

set a new standard and offer a brighter

future for heavy duty equipment. Since

the work day does not necessarily start

at dawn and end at dusk, miners need

powerful illumination, not only for work

to be effi cient but also to maintain safety

in darkness. The Sculptor LED N60XX is

the world’s fi rst all LED, ECE-approved

combination headlight in serial production.

Developed for the most demanding

working environments around the world,

the lamp offers headlight, park light and

180° indicator in one application.

Nordic Lights’ Quake dampening system takes the durability of headlamps to a whole new level. The combination headlight withstands shocks of 60 G and vibration of 15.3 Grms at 24-2,000 Hz. The LED diodes have much higher vibration resistance compared to halogen bulbs.

Cooling is effectively handled by thermal transfer through the alloy housing to the cooling lamellas at the back.

Directional Core Drilling

Devico will exhibit its latest surveying

product line. The company invites miners

to visit the stand and learn why “smarter

exploration’” can be summed up by three

letters: DCD. When seeking to maximize

exploration budgets, Directional Core

Drilling (DCD) is often the solution. Devico

offers DCD services worldwide. Many

drilling contractors and mining companies

have used the technique to increase

precision, reach multiple remote targets

with continuous coring, save time and

cost, make wiser decisions, and successfully

improve profitability.

Abrasive-resistant Solutions

Manex AB (Stand 175), Belzona’s distributor

in Sweden, will showcase innovative

solutions to erosion and abrasion

in liquid and solids handling equipment.

Belzona 1800 Series resins, containing

coarse and fi ne particles, effectively resist

abrasive media at low impingement

angles. The company’s line of elastomers,

in turn, are recommended at 60º–90º

impingement angles, because much

of the impact energy can be dissipated

through elastic deformation. Finally, for

erosion-corrosion repair and prevention,

Belzona 1300 Series materials with ceramic

fi llers perform exceptionally well in

immersed conditions. Visitors will also be

able to use an interactive display table to

navigate through a mine and see typical

problems that Belzona can remedy.

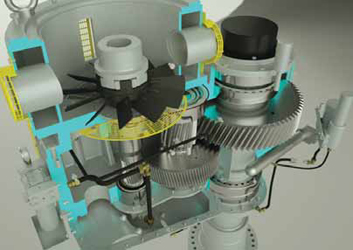

Vertical-mounted Gear Units for Agitators

Santasalo will showcase its AMF vertical-

mounted gear units. By incorporating

a bidirectional axial fan, optimized housing

design and additional new features,

the AMF vertical gear unit eliminates

the need for external cooling in extreme

ambient conditions. These units feature

Santasalo’s proven drive technology, in

operation in thousands of vertical mixing

applications around the world. Direct-

drive construction with electrical

motor and fl exible HSS coupling ensures

high effi ciency, while the highly optimized

gear unit layout results in cost savings

and a smaller footprint.

Santasalo already delivered the fi rst order for the AMF gear unit series in Kazakhstan (fi ve units) and two additional projects are currently being delivered for fi ne grinding applications in U.S. (six units), and Australia (three units).

Real-time Slope Monitoring

Replacing the previous Real Aperture

Radar (RAR) technology with Synthetic

Aperture Radar (SAR), IDS allowed

mine slope monitoring systems to move

from monitoring focused areas to entire

pit walls at a high resolution. In 2012,

IDS took another step forward, adding a

new dimension with the FPM360 system,

which enables a mine to integrate data

from multiple IBIS radars through a single

user interface to provide full coverage

of an entire pit.

Currently, the IBIS radar family offers the right solution for every mine slope monitoring need: the IBIS-FM longrange solution up to 4.5 km; the IBISFMT mobile long-range version, which is easily towable by a light vehicle; and the IBIS-Rover mobile medium-range radar for broad area slope monitoring. The only Synthetic Aperture Radar with a rotating antenna capability, the IBIS-Rover provides a 270° fi eld of view with a scan time of just 4 minutes.

At Euro Mine Expo 2016, IDS will present revolutionary developments in radar monitoring: the IBIS-FB and IBIS Guardian TrueVector. IBIS-FB is a remote sensing monitoring system designed to support the assessment of blasting operations and control their impact both on the pit slopes and nearby structures. IBIS-FB integrates standard vibration monitoring systems providing remote broad area measurements of ground vibrations with high accuracy. After every single blast, IBIS-FB measures a range of performance indexes at multiple points at long distances, even allowing data to be received from within inaccessible areas that traditional monitoring systems can’t monitor.

IBIS Guardian TrueVector is a feature- rich software suite for the interpretation of IBIS radar data and the management of slope stability risks in open-pit mining operations. With the TrueVector technology, IBIS Guardian is able to resolve the spatial direction of displacement vectors for hundreds of thousands of overlapping radar pixels that have been monitored simultaneously by two or more radar systems. Accuracy is sub-millimetric. No prisms, markers or refl ectors are required on the slope, instead, the IBIS systems rely on natural backscattered information to rapidly resolve spatially dense and continuous x, y, z, displacement information.

Vertical Access Solutions

Alimak Hek is a global market leader

and pioneer in designing, developing,

manufacturing and servicing industrial

rack-and-pinion vertical access solutions.

More than raise climbers, they are wellknown

worldwide for providing high-quality

hoists, elevators and platforms.

Alimak Hek recently completed a shaft refurbishment project for the Tauern Tunnel in the Austrian Alps. The Tauern Autobahn near Salzburg serves as an important north-south connection in region. The 6,500-m tunnel tubes are equipped with full cross ventilation and each tube is divided into four ventilation zones. Air handling units are located at the northand south portal, as well as in a cavern between both tubes in the middle of the tunnel.

Both Alimak elevators were ready for refurbishment after nearly 50 years of use. Because of the special confi guration, new elevator cages could not be installed easily. Therefore, the elevators, the cable winch necessary for the operation, the horizontal carriage and the electrical control cabinets, as well as the transformers, were refurbished.

The project was timed to minimize traffi c interruption as much as possible. During the early autumn months, the elevator cages, electrical cabinets and winches were dismantled. Using chain hoists, muscle power, precision and a special loading crane, these parts were brought through the top of the shaft.

Specially constructed equipment was also used at the bottom of the shaft to disassemble the horizontal carriage, winch and electrical cabinets: A HEK MSM Super mast climbing work platform transported the equipment from the recess to the shaft base.

Refurbishment was completed in an ISO-certifi ed Alimak Hek production facility in Skellefteå. After structural and electrical engineering tests, all components still usable were cleaned, sandblasted, resealed and freshly painted. In addition to the Alimak components, the access stairs and railing in the recess of the supply air lift were cleaned, and the protective housing of the horizontal carriage was refurbished.

Completely refurbished and fi tted with new safety devices, gears and motors, the components began their journey back to their place of origin. Thanks to the experience gained during the disassembly and with the help of the equipment retained, the special elevator installation was able to resume its service after successful installation.

Euro Mine Expo 2016 Conference Program

(Preliminary as of April 4, 2016)

Conference Opening, Tuesday, June 14 (1-2:30 p.m.)

Welcoming Remarks: Lennart Gustafsson, chairman of Georange

Government and Keynote Address

Innovation & Business Development (3:00-6:00 p.m.)

Chaired by Jenny Greberg, Luleå University of Technology (LTU)

Mining Redesigned: Equipment and Technology Needs for the

Future

May Hermanus, executive director, Natural Resources and

Environmental Unit of the Council for Scientifi c and Industrial

Research (CSIR) South Africa

What’s the role of KIC and other EU Initiatives?

Pär Johansson, director of commercialization, LTU Business

Maria Magdalena Holmgren, manager EIT Raw Materials Northern

Co-Location Centre

Why 5G can improve safety and productivity underground

Peter Burman, program manager mine automation, Boliden

Opportunities for Local Economic Linkages – the Case of Southern

Africa

Johannes Danz, program offi cer at the Federal Institute for Geosciences

and Natural Resources, BGR Germany

Sustainability in Action Wednesday, June 15 (9 a.m.-Noon)

Chaired by Deborah Craig, International Women in Mining

The Fossil Free Mine

Karl-Erik Rånman, Boliden

A Path Toward Sustainability

Helena Ranängen, PhD., Industrial Environmental Management,

LTU, and Åsa Lindman, LTU

Women in Mining

Georgette Barnes, Ghananian entrepreneur and owner of drilling

company, chairwoman of Ghana Georgette Barnes Ltd.

Health and Safety in Focus

Glenn Mpufane, head mining industry, IndustriAll global union

Prospecting for Secondary raw materials in the Urban Mine and

Mining Wastes – ProSum

Sarah Downes, MSc, Environmental Quality Management, Repic.

Market Outlook: A Light at the End of the Tunnel?)

Thursday, June 16 (9 a.m.-Noon)

Chaired by Anton Löf, SNL Metals & Mining

New Corporate Landscape

John Mayer, partner/mining analyst, SP Angel, London

Metals Markets: Copper, Gold, Zinc, Silver and Lead

Dr. Chris Hinde, director, reports, SNL Metals & Mining

The Iron Ore Industry, Market and Prices

Melinda Moore, head of iron ore, London Standard Bank

“Still Rockin” – 10 Good Things about Today’s Mining Industry

Dr. Mike Armitage, chairman SRK Consulting

Closing Remarks

Magnus Eriksson, professor, Mineral Economics, LTU and

co-founder and partner of the Raw Materials Group (RMG).

Tommy Abrahamsson, CEO, Nolia AB