The latest generation of mobile conveyor-based heap-leach stacking equipment, such as the Superior Industries

The latest generation of mobile conveyor-based heap-leach stacking equipment, such as the Superior Industries

system shown here, has auto-leveling features that allow

consistent material placement on the pad even when

the radial stacker has to travel over uneven ground.

Since its commercial introduction to the

mining industry in the late 1960s, heap

leaching of low-grade ores to recover valuable

commodities—mostly gold and copper,

but also nickel, uranium and to a lesser

extent, vanadium and other metals—has

grown steadily and proven to be a flexible

and less-capital-intensive approach that

appeals to both ends of the industry’s corporate

spectrum, from new or smaller companies

looking for a way to get a property

into production as quickly and cheaply as

possible, to established producers that

want to monetize marginal mineralization.

It’s a steadily evolving technology that

has been able to accommodate mineralogical

changes in the mining landscape, and

it has been user-friendly in terms of adopting

new forms of technology that offer the

prospect of lower pad construction and

closing costs, more efficient fluids application

and collection, and ultimately, higher

recovery rates.

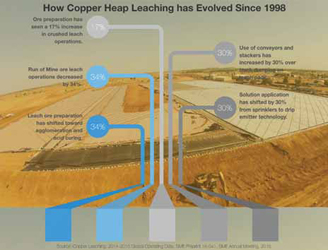

Many of the long-term trends and

changes in heap-leach operations are highlighted

in a recent paper presented at the

2016 Society for Mining, Metallurgy and

Exploration (SME) Annual Meeting* that

updated a survey of copper leach producers

conducted in 1998. The authors sent

questionnaires to 40 copper-leach operators,

including properties that were contacted

in the original survey and are still in

operation; 28 operations responded.

Among the broad trends identified by

the survey results is a geographical shift in

overall capacity of copper SX-EW plants—

Latin America gained 12%, moving from

46% to 58% at the expense of the southwestern

U.S., which dropped from 42% to

38%; and Africa, which didn’t register on

the recent survey after holding a 9% share

in 1988. Australia gained one point, growing

from 3% to 4%.

The results also showed a swing in primary

copper mineralogy to mixed leach-ore

types: in 1988, oxide ore accounted for 29%

and sulphide 14%, with oxide/sulphide

mixed ores representing 57%. In the updated

survey, oxides dropped to 20%, sulphides

to 12%, and mixed ores grew to 68%. Other

notable results from the survey are shown in

the accompanying figure.

To identify ways in which industry suppliers

are responding to the heap-leach

sector’s changing conditions and requirements,

E&MJ conducted an informal survey

of its own; we took a look at recent

product announcements, spoke with supplier

representatives, and put together a

brief sampling of the newest technologies

available to the industry. Among those, we

found an increasing emphasis on automation

and better control systems for material

handling equipment—not a surprising

result, as leach pad footprint size and

height continue to grow while the industry

attempts to pare construction and labor

costs as it searches for solutions to optimize

metal recovery and its return on heapleach

project investment.

Maintaining the Flow

As the industry shifts from truck-dump pad

loading to conveyor-based stacker/spreader

systems, the focus changes from what is

almost a batch-loading process to one that

is more or less continuous. Careful planning

is necessary—involving a wide range of disciplines—

to extract the best performance

from these highly engineered materialshandling

systems. We spoke with Matthew

Hanson, business development manager

at Superior Industries, a Minnesota-based

supplier of conveyor systems and components,

about how the company goes about

laying the basic groundwork for recommending

a leach-pad loading system package

to its customers.

E&MJ : What are the basic set of project-specific

factors that Superior’s engineers take

into account when specifying an equipment

package for a given heap-leach operation?

Hanson: The first area we look at is material

characteristics—the type of material,

its PCF, size and tons per hour requirement.

With this information we can then

size the belt width of the conveyor system.

The next step would be to look at the pad

layout and the stacking plan in order to

properly size length and number of grass-

hopper conveyors required. As soon as we

have determined the grasshopper length,

we will then size our HIC (Horizontal Index

Conveyor) based off of this. The last step

would be to determine the cell width and

pile height to correctly size the stacker.

E&MJ :

What are some of the individual site

characteristics you encounter that require

additional engineering or customization?

Hanson:

Weather conditions in any given

area will always need to be looked at. Rain,

snow and wind cannot be overlooked. The

valley fill sites are always more complex

than a standard site. One aspect that

needs to be looked at thoroughly is the

power travel for all the conveyors—the

HIC will need to be sized to tow the stacker

and itself up the worst incline. The radial

travel of the stacker also must be taken

into account.

E&MJ : Can prospective heap-leach customers

take advantage of any recent

advances in materials, control systems,

energy-saving technology or other aspects

of conveyor equipment design to improve

the efficiency of their operation?

Hanson: Our latest advance is an auto level

system on our stacker. This technology

allows us to keep the stacker level while

moving radially on an uneven terrain. This

will be very helpful in regard to belt tracking

and with material spillage.

Last year, Superior updated its telescoping

radial stacker automation program, which

didn’t affect the physical function of the

machine but provided a user-friendly screen

design featuring enhanced graphics and

onscreen buttons to help operators navigate

the software more easily, among a list of other

improvements aimed at user convenience.

Controlling the Flow

For larger leach-pad stacking systems, an integrated

control system is essential to achieve

smooth, uninterrupted material flow at high

volume levels. As an example, FLSmidth engineered

and delivered a heap-leach stacking

system for CNMC Luanshya Copper Mines

PLC, located in Luanshya, Zambia, designed

to load more than 1,000 t/h of agglomerated

copper ore onto the mine’s pads.

The order included an overland (OL)

conveyor, a mobile overland tripper (MOT),

20 grasshopper conveyors, a mobile transfer

and bridge conveyor, and an automated

radial stacking conveyor. One FLSmidth

team designed and detailed the leach pad

stacking conveyors, and another team

designed and detailed the OL conveyor and

MOT. All conveyor structures were fabricated

in South Africa.

The MOT, which straddles the OL conveyor,

was equipped with two driving stations

so it could be driven to the required

stacking location along the OL conveyor.

The MOT has intelligent anti-collision

instrumentation to assist the operator in

keeping it located on the overland centerline

while being driven, thus preventing a

potential collision that would damage the

OL conveyor stringers.

The bridge conveyor was configured

with hydraulically driven tracks that could

be manually or remotely driven via an operator-

controlled radio pendent. The bridge

had a separate onboard generator used to

power the bridge track drives while towing

the radial stacker over long distances. The

radial stacker included an elevated operator

control cabin featuring an HMI and

manual operator controls.

An auto-stacking solution was developed

to provide the radial stacker with full operational

capabilities in automatic mode. To do

this, a mathematical auto-stacking solution

was formulated in-house on a conceptual

level and refined through numerous design

iterations. The final auto-stacking algorithms

required specialized programmable

logic controller coding and included processes

for cone stacking at low tonnages,

continuous stacking and manual stacking.

Two HMI modules were supplied—one

in the field at the head end of the OL conveyor

and the other in the operator control

room on the radial stacker. FLSmidth provided

a wireless network for the transfer of

all instrument signals from each mobile

conveyor to both HMIs, which allows one

operator to efficiently pinpoint a technical

problem. The wireless network is used for

indication only, while all controls were

hardwired on each mobile conveyor.

A group-start function can be controlled

from the radial stacker’s HMI operator

interface. Maintenance mode can be

selected from dedicated conveyor local

control system panels so that each piece of

equipment can be started individually.

Stockpile height and slew speed are determined

by two radar ultrasonic level sensors

located on the mobile slinger. The control

algorithm of the radial stacker was programmed

to suit the design requirements

in stockpiling height (trough to peak).

Intelligent pull keys were used on the

overland conveyor with feedback to the

HMIs, where status could be monitored in

defined zones. Thermistors were supplied

on the 250-kW overland conveyor drive

motor to monitor winding temperatures. All

of the system’s gearboxes are monitored for

oil temperature, and fluid couplings were

supplied with thermo switches. All process

and control instruments were hardwired

back to their respective mobile conveyors.

Monitoring the Flow

The use of automation in heap-leach operations

extends to leach-solution application

practices, as well. Earlier this year, Netafim

USA, a manufacturer of dripline products

for the mining industry, called attention to

its new monitoring and control solution

designed to improve operational productivity.

Available as a complete package of software,

hardware and support equipment,

Netafim’s system uses proven radio and

cell-based technology to provide real-time

control and monitoring of the leaching

process from a single location. The system

provides the capability to remotely monitor

solution flow onto the pad, and immediately

respond to any problems detected.

“Automation and data logging technologies

have been incorporated into nearly

every facet of modern mining operations,

but when it comes to the leaching process…

most mines still employ the very

inefficient process of manual monitoring

and troubleshooting,” said Karen McHale,

North American sales and engineering

manager for Netafim USA’s Mining

Division. “We are able to give mines precision

control technology that eliminates the

need for teams of workers to manually walk

miles and miles of leach pads on a daily

basis in search of a potential problem.”

The automated system incorporates

moveable equipment that contain radio or

cellular controls, control and air valves,

meters, gauges and other components

designed to collect and store crucial data

that mine operators can use to improve

operations and maintenance, as well as to

identify problems such as line plugging

that can wreak havoc on a leaching system.

“Infusing automation into the leaching

process means mines can work with smaller

teams supported by a real-time assessment

of the leaching process without leaving

the office. By turning on the leach pad,

mines are able to benefit from increased

efficiency and reallocate manpower needs

to other areas of the mining operation,”

said McHale.

E&MJ spoke with Mike Stoll, director of

sales and marketing for Netafim USA’s

Industrial division, about the design intent

and specifics of the system:

E&MJ : How has Netafim incorporated

automation into the leach process?

Stoll: Netafim is a solutions provider in the

mining industry that includes dripline, air

vents, flowmeters, flushing packages and

other valves. From the perspective of how

Netafim dripline products are utilized in

heap leaching, the process has not historically

featured very much automation. That

means that there is a large manpower

requirement to oversee the day-to-day performance

of the pads. The Netafim system

minimizes the manpower required and

allows the site to direct personnel to a specific

and known problem. It does this by providing

real-time data to a central location so

that any maintenance that needs to be performed

is being done because it is required

rather than just being done to cover bases.

Netafim is taking manual operation out

of the equipment in the leach circuit and

allowing data to be collected regularly and

equipment to be turned on/off from a central

location. Personnel do not have to walk

the pad to collect data or flush the driplines.

It can all be done from a laptop.

E&MJ : What are the primary components

of Netafim’s automation technology for

leach pads?

Stoll : The control and automation system

consists of Remote Terminal Units (RTUs),

antennas, repeaters, base station and the

software (server or cloud-based) to operate

it. The equipment that can be controlled

consists of valves, flow meters, sensors and

other equipment or instrumentation.

From the standpoint of cost and support,

the ability of the Netafim system to

be cloud-based is one of its most attractive

features. Imagine a mine operator with two

or more sites either in close proximity or

even hundreds or thousands of miles apart,

and each site needs the level of control the

system provides. By using a cloud-based

system rather than having individual servers

at each site, the company not only

saves thousands of dollars in equipment,

setup and maintenance, but being cloudbased

allows the mine to oversee all controlled

activities from an individual site as

well as from other authorized locations.

E&MJ : How are the primary components of

the system deployed?

Stoll : The system provides an open platform

that makes it customizable and expandable.

It goes from very simple data

collection of a flow meter to collecting data

and controlling all the equipment installed

from a central location.

Pad components can be deployed in

any variety of ways that include simply

physically connecting the components into

the piping network or in a way that makes

them portable as the pad expands and

grows. As with other equipment on a pad,

the ability to move components quickly

and with a minimum of damage is critical.

Netafim works with the individual site on

identifying the needed components but

each site determines the best way to set

the components up.

E&MJ : Is the system easily scalable to

allow expansion of capacity?

Stoll : Yes. One of the Netafim system’s key

attributes is its ability to not only scale

upward or downward but also to allow basic

monitoring or very advanced monitoring and

control of any number of inputs. The value

to the mine site is that as or if their needs

become more complex, the Netafim system

can grow with them without starting anew.

Leister’s newest GEOSTAR wedge welder can fasten plastic pad liner sheets together at up to 39 ft per minute.

Leister’s newest GEOSTAR wedge welder can fasten plastic pad liner sheets together at up to 39 ft per minute.

E&MJ : How can this data be utilized to

improve performance?

Stoll : One of the key maintenance issues

with heap leaching is management of the

dripline system and keeping the driplines

operating at peak performance. The typically

unfiltered solution being delivered to

the pad can create issues with drip emitters

clogging and while the clogging can

frequently be remedied, the manpower

needed to do that can be expensive.

By designing the pads in a way whereby

the ends of the dripline laterals can be

opened so additional flow is pushed

through the dripline, the driplines can be

“scoured” with the increased flow which

creates turbulence in the dripline and dislodges

contaminants from the inside walls

of the tubing. This is a technique used in

many industries including wastewater,

flushing water mains, etc.

E&MJ : Can the system be tailored to meet

specific operational objectives or reporting

requirements?

Stoll :The scalability of the Netafim system

is purposely designed to support any level of

control from the most basic to very complex.

E&MJ : Does the system require additional

training for proper use?

Stoll : Yes. Netafim offers training to the

local technical personal on installation,

troubleshooting and system operation.

Service personnel are available for site visits

and the site can call our office for troubleshooting

help as well.

Containing the Flow

Not all technological advances take place at

the top of the heap, however. The care and

attention given to installation of the thermoplastic

sheets used in pad liner systems is

an important factor in pad performance and

longevity (See E&MJ, May 2015, Trickle

Down Economy, pp. 40–45). Accordingly,

Leister Technologies, part of the Switzerland-

based Leister Group, introduced a new

GEOSTAR wedge-based welder last year

designed to quickly and efficiently join

together those plastic sheets.

According to Steve Hobbs, Leister’s

geo-systems manager for North America,

“The GEOSTAR is a game changer,” providing

nominal output of up to 2,800 W

and peak welding speeds of up to 39

ft/minute, The operating unit (eDrive) provides

operators the convenience of a large

monitor with digital real-time display of

three key parameters?joint pressure,

speed and wedge temperature—as well as

an integrated voltage display that enables

ongoing monitoring of welding parameters

and voltage throughout the work process.

The GEOSTAR provides one-hand operation,

integrated clamp/handle engagement

and three parking and maintenance

positions. Leister notes that the unit’s generous

spatial dimensions for material input

were taken into account in the design of

the cast aluminum frame in order to accelerate

the starting process, and according to

the company, the new wedge geometry

allows the material to glide smoothly

through the machine.

As featured in Womp 2016 Vol 03 - www.womp-int.com