According to the author, successful mining maintenance isn’t exclusively a

maintenance-department effort. Worldclass maintenance status is only achieved when

‘world class’ is the performance norm for an entire mine.

Achieving World-class Mining

Maintenance: Step 1—Identify Needs

and Priorities

In a six-part series starting this month, the author provides a detailed road map for

developing and sustaining a top-notch mine maintenance program

By Paul Tomlingson

But what does world class mean and

how is it achieved? It is not the label

“world class” that is important. Rather, it

is the accomplishments realized that

yield the benefits described as world

class. Over the course of this article, the

actions needed to achieve world-class

mining maintenance status are explained

in six consecutive steps that lead to

recognition as a first-rate organization

with productive employees performing

quality work, and consistently reliable

equipment to meet production and quality

goals.

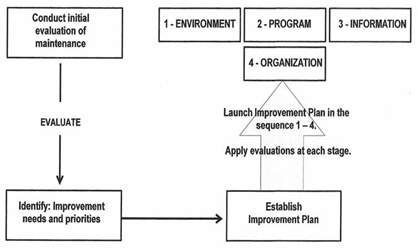

The six steps are:

• Identify improvement needs and priorities

Start by conducting an evaluation

to identify improvement needs and priorities.

Evaluations should include all

mine departments as well as management

so that all actions and policies

that affect maintenance can be examined.

No improvement action can occur

nor will it be successful unless the situations

that preclude effective performance

are identified and actions taken

to correct them.

• Ensure support for maintenance. Create

a positive mine-wide maintenance working

environment by attaining the full

cooperation and support from all mining

departments and assuring mine management

reinforcement. There are no

world-class maintenance organizations.

Rather, there are world-class mining

organizations that include a world-class

maintenance organization. Maintenance,

by itself, is a service provider.

Successful mining maintenance is not

a “stand-alone” maintenance effort.

World-class maintenance status is only

achieved when world class is the

required status of the total mine.

• Establish an efficient program. Develop,

document, test and implement a quality

maintenance program to spell out

how work is requested, identified, classified,

planned, scheduled, assigned,

controlled, measured, and assessed to

ensure continuous improvement and

sustained, effective performance. Ensure

the entire mining operation understands

what maintenance does, who

does what, how and why so they will see

their supporting and cooperative maintenance-

related roles clearly and contribute

more effectively to the success

of the total operation.

• Ensure effective use of information. A

quality information system is the

shared communications network system

that controls execution of the

mine’s maintenance program. It also

controls other essential mining activities

such as inventory control and purchasing.

The use of a common integrated

system implies the cooperative

use and interchange of information. Its

proper utilization enhances maintenance

performance and guides the progressive

steps toward the mine’s “worldclass”

objective.

• Organize properly. The maintenance

program identifies what maintenance

does, who does what, how and why.

Program details can help to identify the

best maintenance organization and

specify the duties and responsibilities

for carrying out the program. In addition,

the program spells out the maintenance-

related interactions between

mining departments by advising thebest ways in which their personnel can

support maintenance.

• Re-evaluate and confirm. By reapplying

the evaluation process established in

Step 1, achievement of the improvement

needs established in the initial evaluation

can be confirmed and verification

made that the revised and improved total

mining organization can meet and sustain

world class performance.

Characteristics

World-class maintenance is the pinnacle of

achievement for maintenance organizations.

It results when the organization carries

out an effective program, utilizes quality

information and organizes properly to

help ensure a profitable mining operation.

These operations will be characterized,

for example, by a cooperative production

group and supportive staff organizationslike warehousing. They will be led by

visionary mine managers who have created

an environment for success with a sound

business plan embodying clear departmental

objectives and policies that guarantee

harmonious departmental interaction.

Performance Standards and Evaluations

Standards should be established as

goals for organizations seeking improvement.

Once established, an evaluation

procedure should be applied to measure

a candidate organization’s performance

against the standards. Minimum levels

of achievement should be set in order

to gain necessary improvements. Unfortunately,

no body currently exists to

administer such evaluations as does

ISO (the International Organization for

Standardization) and their certification

requirements. Therefore, emphasis

should be given to developing suitable

standards and the organization can

apply any evaluation technique providing

it yields information on how well standards

are being met and whether performance

progress is being made. Many

mining organizations utilize evaluation

teams made up of personnel within their

organizations who possess suitable skills

and backgrounds. Often, such teams

come from sister mines in which there

are reciprocal evaluation arrangements.

How are Standards Developed?

Standards can be developed from a number

of sources: Existing KPI’s (key performance

indicators), the study of ISO

55000 (asset management and asset

management systems), the principles of

maintenance management, benchmarking

and highly successful in-house operations

are potential sources. But standards

must satisfy the special, unique

operating environment of the mining

industry. The development and acceptance

of performance standards must be

the byproduct of successful maintenance

operations in which procedures are

established that consistently produce

outstanding results.

For example, preventive maintenance (PM) procedures that reduce emergency repairs and extend equipment life might be considered. But when PM procedures enhanced with predictive techniques always find equipment problems far in advance of equipment failure to ensure that the majority of maintenance work can be planned and scheduled, those procedures could be seriously considered as standards. Standards for maintenance goals reach far beyond internal procedures like the conduct of preventive maintenance, planning and scheduling.

Standards must also embrace the working relationships between departments to result in harmonious professional interactions. Operations, for example, must apply and adhere to standards, which cause them to utilize maintenance services effectively. Similarly, warehousing, purchasing or accounting must recognize and adhere to standards. Even the mine manager’s actions must be included in the standards. Has he, for example, taken adequate steps to ensure that all departments are properly supporting maintenance?

If for example, a KPI requiring 85% PM schedule compliance is the only standard for PM, it is inadequate. An illustrative PM standard is illustrated in the accompanying sidebar above.

Once standards have been established, tested and accepted, the organization can determine the most effective way to evaluate compliance with the standards or assess progress in meeting them.

Evaluation Strategy

No improvement can be initiated unless

the current situation is known. Improvement

is only possible when we learn

whether maintenance is a good organization

only needing a decent program to follow

or an organization besieged with

unreasonable demands placed on an inadequate

workforce. Evaluations answer this

by providing the “as-is” status of current

performance then utilizing the results to

develop an improvement plan. Regardless

of how standards are created, an evaluation

procedure is required to discover necessary

improvement actions and measure

progress toward their achievement.

It is not unusual to witness resistance

to being evaluated. This is especially true

when worker performance can be adversely

affected by activities over which they

have little control such as warehousing

failing to deliver needed materials on

time. An evaluation strategy such as that

presented below can overcome such

resistance, particularly when every department

is equally evaluated. Consider:

Developing a policy for evaluations—A

management policy requiring that all

departments be evaluated on a regular,

continuing basis will preclude any doubt

as to its value and redirect the energy of

resistance into efforts to prepare for

evaluations.

Providing advance notification—Advise personnel about the evaluation and make a preliminary statement about its content, purpose and use of the results. This will eliminate surprises and emphasize the policy of regular, continuing evaluations.

Educating personnel—Explain that the

evaluation is a checklist describing what

should be done. Results describe how

well they did and provide a basis for

improvement. The evaluation will identify

what is done well and what was done

poorly. It is an opportunity to help all

departments account for their contribution

to mine objectives. Emphasize the

positive aspects of the evaluation

through education.

Change unfavorable misconceptions

of evaluations by telling personnel that

the evaluation is a means of finding out

how they can do better. Avoid comparing

evaluation results with other mining

organizations unless there is a clear

benchmark accepted by all. The sponsor

of multiple mining operations evaluations,

usually a general manager, must

convey a supportive attitude. He should

provide encouragement to conduct the

evaluation and follow up to see that

something constructive is done with the

results. If help beyond the resources of a

single operation is necessary for improvement,

the sponsor can help cement good

relations by providing it.

Education continues through the evaluation

process and into the results. In

individual mining operations, for example,

local managers will want to know

how well their policies are understood

and how effectively the procedures based

on those policies are being carried out.

Let them know. Although they are concerned

with the quality of the maintenance

program, they will be equally interested

in learning how well, for example,

production cooperates with the program.

Therefore, in a multimine environment,

they will be less concerned with what

others may think and get on with the

evaluation. They should assume that

every other plant is interested and concerned

but, also ready to help them

rather than compete with them.

Scheduling the evaluation—Schedule the evaluation carefully to avoid conflicts. Peak vacation periods may find key personnel away from the mine. Similarly, recent personnel changes could limit knowledge of evaluation points, and personnel cutbacks or staff reductions might affect attitudes. In general, the evaluation should be carried out in a stabilized situation with few distracting conditions. With suitable advance notice, the organization can prepare for the evaluation and look forward to learning how they are doing. When evaluations are conducted on a regular, continuing basis, people will be constantly preparing thus, performing better. In addition, they will look forward to the evaluation as an opportunity to demonstrate their progress. Generally, if maintenance personnel feel that the evaluation is constructive, they will prepare for it without hesitation. In subsequent evaluations, if they have accepted the evaluations and are convinced of their value, they will make a conscious effort to improve on previous results. Soon the concept of evaluations permeates the entire organization and their outlook is transformed from one of fearing evaluations to welcoming them and their potential benefits.

Publicizing the content of the evaluation— By publicizing evaluation content, personnel can prepare in advance. This is unlikely to constitute a dramatic shift in performance. Reports will be ready and personnel scheduled for interviews will be prepared.

Using the most appropriate evaluation technique—Evaluation techniques should be considered based on the mining situation. Some operations may require an evaluation in which every detail must be scrutinized. Other operations, having established the essential pattern of evaluations, may simply check progress by measuring only a few critical areas. Other mines utilize forms of self-evaluations made possible by the existence of standards they have set for themselves.

Announcing evaluation results—By sharing evaluation results, the good and the bad are acknowledged with an expectation of a commitment to help attain improvements. Discussion is encouraged often resulting in the best way to accomplish improvements. Conversely, keeping the results a secret will decrease credibility and make improvement actions more difficult.

Taking immediate action on evaluation

results—The most convincing way to

demonstrate that the evaluation was a

constructive step is to organize an

improvement effort immediately. Obtain

commitment to the constructive use of

the results by converting them into an

improvement plan and immediately

organizing the improvement effort. This

is the main objective of the evaluation. If

the evaluation is one of a series, results

should be compared with the previous

evaluation. This demonstrates progress

as well as the identification of areas that

need more work.

Separate the good from the bad. Offer

congratulations on the good performances

and organize the activities requiring

improvement into priorities. Actively

solicit help from anyone capable of providing

it. If there are corrective actions

beyond the capability of maintenance,

don't hesitate to seek help. Mine managers

are usually pleased to be asked to

help. It is also gratifying to learn that corporate

managers, particularly those

responsible for multiple operations, are

eager to help as well.

Set up an advisory group and let them

determine why certain ratings were poor.

Then seek their recommendations for

improvement. Change the members of

the advisory group frequently to encourage

different views. As recommendations

are made, try them in test areas before

attempting mine-wide implementation.

Announcing gains from the maintenance evaluation—As soon as any gains that can be attributed to the evaluation can be identified, announce them and give credit to the appropriate personnel. People like to know how they did. Tell them. In the process, candor will invariably encourage a greater effort in future evaluations.

Specifying the dates of the next maintenance evaluation—Announce the dates of the next evaluation immediately to reinforce the policy of continuing evaluations. Identify any additional activities that will be evaluated. As necessary, establish new, higher performance targets for the next evaluation.

Look at the Big Picture First

World-class maintenance is an objective

that requires a total mine effort. It cannot

be achieved through maintenance efforts

alone. By starting the journey toward

world class status with an evaluation of

the total mining operation all of the factors

that impact maintenance performance

are assessed.

The initial evaluation defines and prioritizes overall mine improvement needs as they relate to maintenance. Once these needs have been identified and prioritized the maintenance working environment must be aligned so that maintenance can work harmoniously with all departments.

Next, the maintenance program must be developed, documented, implemented and explained, mine-wide, so that internal maintenance activities and interdepartmental actions can be carried out in an atmosphere of full cooperation and support. Then, quality, timely and accurate information must be applied so that the program can be controlled and managed effectively. Then, a suitable maintenance organization based on the details of the maintenance program can be determined and implemented.

With these elements in place, the organization can carry out the maintenance program effectively. Finally, evaluations are utilized to ensure that each phase of the journey to world-class maintenance has been satisfactorily accomplished and when that goal has been achieved all of its gains are able to be sustained.

Preventive Maintenance (PM) Standard

The Preventative Maintenance (PM) program should successfully

avoid premature equipment failures and extend equipment

life and through timely inspection, condition monitoring, testing,

lubrication, cleaning, adjustment and minor component

replacements. As a result, there should be fewer emergency

repairs and more planned work so that personnel will work more

productively yielding higher quality results, less downtime and

reduced costs. The major elements of a valid standard follow:

• There is a well-defined and publicized PM program understood

by maintenance personnel, all departments and

management.

• Management understands and strongly supports PM by

requiring proof of compliance and its effectiveness.

• The PM program is “detection-oriented” to identify deficiencies

in advance of potential equipment failures.

• PM emphasizes the careful inspection and testing of safety

equipment and conditions.

• PM emphasizes preserving equipment functions and avoiding

consequences of failure.

• PM has reduced the amount and severity of emergency

repairs.

• PM has increased the amount of planned work.

• Manpower needs for each PM service and the entire program

have been established.

• Completion of PM services is verified and management

advised of exceptions.

• New equipment is added to the program and equipment

modifications requiring program service changes are made

without delay.

• The overall PM program is reviewed regularly to ensure its

adequacy.

• PM services are carried out diligently by maintenance personnel

and, as required, equipment operators.

• Supervisors ensure services are complied with and completed

on time.

• Operations cooperate with the program in making equipment

available for schedules.

• Equipment operators perform PM-related tasks completely,

efficiently and correctly, when required.

• Condition-monitoring using predictive techniques (PdM) are

properly integrated into the PM program and skillfully used.

Maintenance personnel interpret and utilize diagnostic information

effectively.

• Each service has a checklist describing required services

and how the service is carried out.

• PM services are properly identified with the work order system

to ensure proper scheduling and control.

• Extensive repairs are not carried out until PM services are

completed and the extent of required repairs is established.

• PM services are scheduled and carried out at correct intervals.

• Services for fixed plant equipment are linked together in routes

to avoid unnecessary travel. PM services for mobile equipment

are scheduled to avoid unnecessary interruption of operations.

• Maintenance and operating personnel collaborate to ensure

program success.

• The PM program yields better overall maintenance performance

resulting in fewer emergencies, more planning, less

downtime and reduced costs.

Next month: Step 2—How to ensure

mine-wide support for maintenance.

Paul D. Tomlingson (pdtmtc@msn.com)

is a Denver-based maintenance management

consultant. His latest book,

“Maintenance in Transition—The Journey

to World-class Maintenance,” contains

the detailed performance standards on

which evaluations discussed in this

series of articles can be conducted.

Copies of the book (ISBN 978-1-4675-

9069-3, 395 pp.) can be purchased

from the author. He welcomes inquiries

concerning these articles.