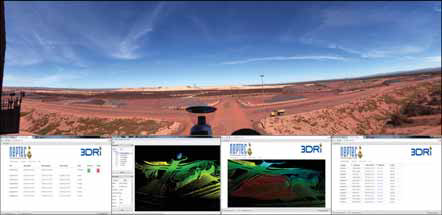

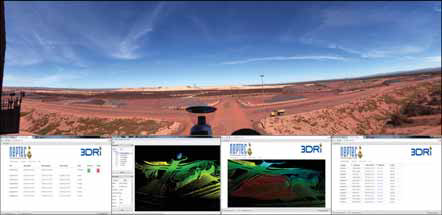

Neptecís 3DRi Stockpile application enables automated stockpile monitoring, using laser scanners deployed

around one or more stockpiles to automatically track material levels and report volumes.

Stockpile Monitoring System Offers Automation

3DRi Stockpiles uses one or several OPAL laser scanners deployed around a cluster of stockpiles at a mine site to automatically monitor stockpile levels and report volumes. The dust-penetrating OPAL scanners, according to Ottawa, Ontariobased Neptec, are specifically designed for harsh, dusty environments and can be deployed around the stockpiles without any special, air-conditioned or heated enclosures. A network of two to four OPAL scanners can be optimized to cover multiple large open-to-the-air stockpiles in a cluster.

3DRi (3-D Real-time intelligence) software technology from Neptec is used to perform all 3-D data processing at the point-of-collection and in real time, eliminating the need and cost of manual acquisition, transmission, and post-processing of huge 3-D point cloud data sets to calculate stockpile volumes.

Through a 3DRi Web interface, users can remotely schedule scanning events, define individual stockpiles in a cluster, and customize the automatic reporting from simple volume reports to point cloud grid and surface files for each individual stockpile. Results can be emailed to users or exported to popular mine planning software packages or enterprise- level mine information systems.