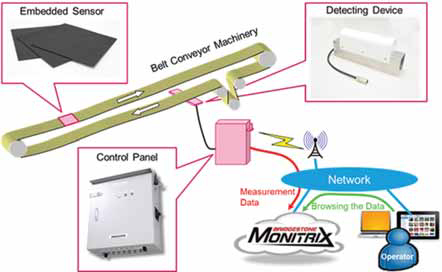

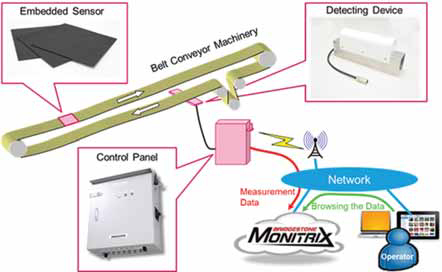

Bridgestone Corp. announced it has

developed a system capable of automatically

assessing conveyor belt wear,

and has released it to the market. The

company also will launch Monitrix, mining

operations support software also

designed by Bridgestone that integrates

conventional maintenance services with

the newly created conveyor belt wear

monitoring system. Bridgestone explained

that checking conveyor belt

wear typically involves measuring the

belt at various points, which requires

temporary system stoppages and associated

production losses. The new conveyer

belt wear monitoring system uses

sensing and communications technology

to enable automatic measurements

of belt thickness through sensors

embedded in the belt. This data is

transmitted to a data collection system

to allow monitoring of wear conditions

without stopping belt conveyor operations.

In addition to minimizing production

losses attributable to system stoppages,

the new technology eliminates

manual measurements, potential errors

associated with manual data entry, further

improving productivity and efficiency.

Bridgestone said it tested the

monitoring system at a mining operation

in Australia.

Monitrix software provides total

management of the new wear monitoring

system, including management of

conveyor belt specifications data, operating

life and stock, and simulations of

wear conditions and replacement

schedules. Bridgestone said it intends

to continue expanding the functionality

of the software.

www.bridgestone.com

As featured in Womp 2015 Vol 03 - www.womp-int.com