Three Steps to Improving Mine Performance

Combining elements from performance improvement programs while focusing on the

people side of the equation proves successful for some underground operations

By Steve Fiscor, Editor-in-Chief

Underground mining processes can be complex, especially when one considers the relationship between development and production. Add to that other variables such as shaft scheduling, delivery of materials, drilling and blasting schedules, mucking, the movement of men and machinery, etc., and the interdependency of related tasks further complicates the situation.

If it were a rock factory, would it be safe to assume that management could also apply the same practices that have improved performance on modern manufacturing plants? No doubt, the mining industry is set in its ways and has been slow to adopt principles, such as continuous improvement. Underground mining is inherently dangerous and mining equipment occasionally faces extremes, which makes the job more of a craft than a process. Some mining companies have also had negative experiences with continuous improvement programs. Some embarked on overreaching plans that ultimately fell short as they lost sight of the goal and failed to keep the miners engaged.

Rather than looking for a silver bullet, perhaps mine planners should get back to basics; plan multiple smaller improvement projects, engage the miners, set achievable goals, measure the results, and praise the accomplishments. Bruce Wesner, managing principal, Life Cycle Engineering (LCE), believes in a focused improvement effort—one that defines a value stream to identify and overcome obstacles that create performance problems.

LCE bills itself as a firm that provides engineering solutions that deliver lasting results by enabling people and organizations to achieve their full potential. Wesner has more than 25 years of maintenance, engineering and management experience. Certified by Prosci as a change management leader, he is adept at applying change management principles to create successful client outcomes.

Wesner discussed some of LCE’s recent successes in the underground hard-rock business at the 2014 Society of Mining Engineers meeting, which was held during February, in Salt Lake City, Utah. The program LCE has developed combines problem-solving aspects of some of the more successful continuous improvement programs with a process that engages people. Once miners understand the end goal and how they are going to get there, Wesner said they will support the effort.

Optimizing to Perform at a

Higher Level

The three steps to improving mine performance are defining the value stream,

defining the projects along with the value

proposition, and implementing an organizational change plan. Before organizations

can determine where they want to go, they

need to understand where they currently

stand. Then, according to Wesner, they

can understand where opportunities exist

to optimize the process and perform at a

higher level. “We concentrate on the people side of the operation,” Wesner said.

“The people piece is the missing part of

most technical implementations.” LCE is

certified in the Prosci change methodology program and the company integrates

that with its technical solutions.

Mine performance optimization is all about the loss elimination, Wesner explained. “As we started to talk about loss with miners, we tried to understand why it’s acceptable to have mobile equipment down for any period of time. Many organizations will say, ‘that’s part of what we do. We blast and equipment gets torn up because we are dealing with heavy stuff,’” he said. Wesner refuses to accept that explanation.

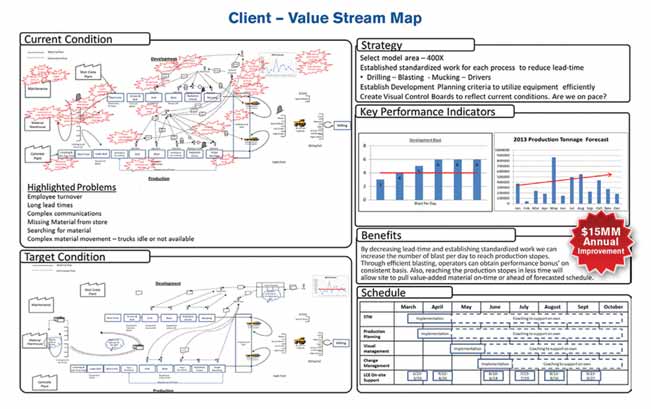

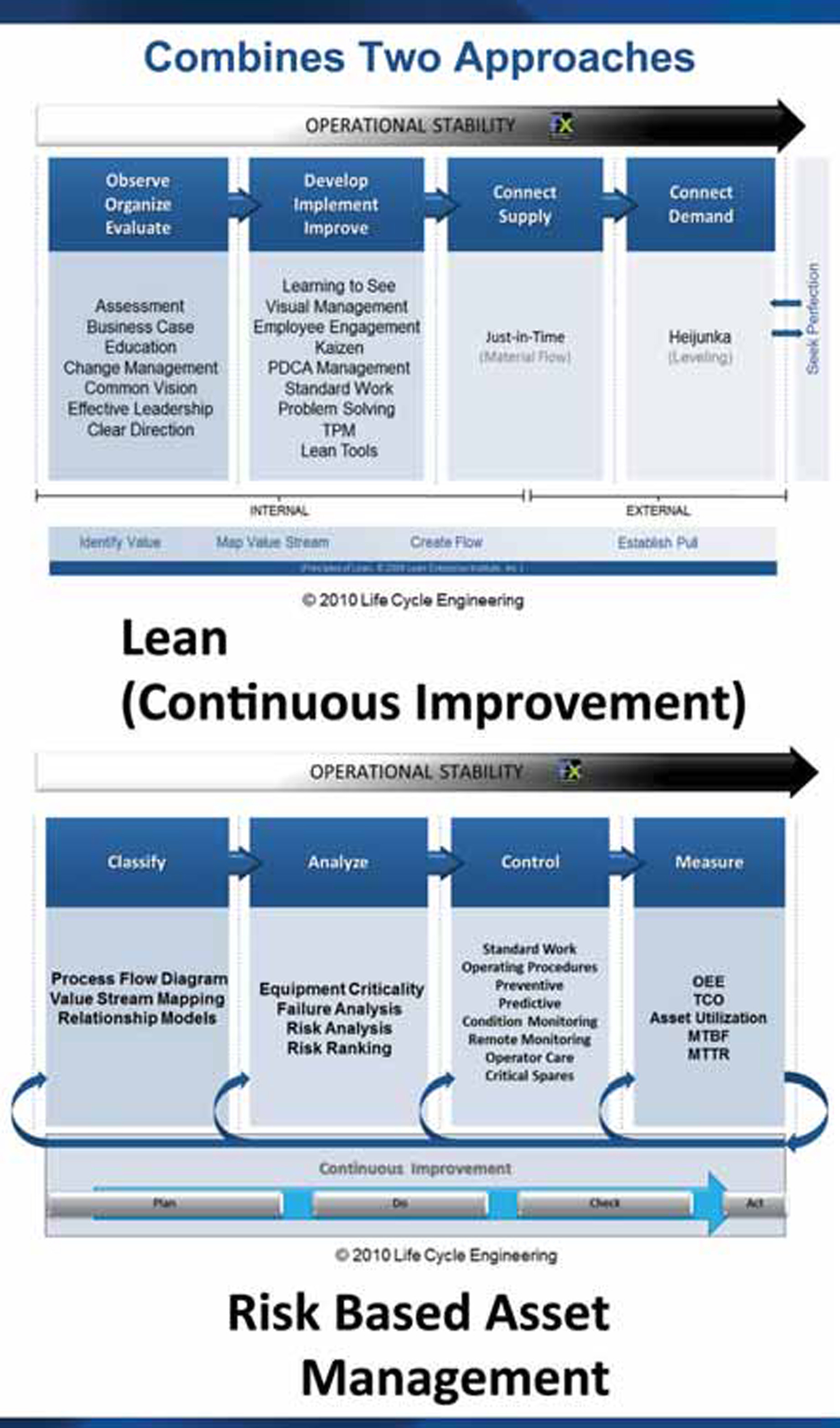

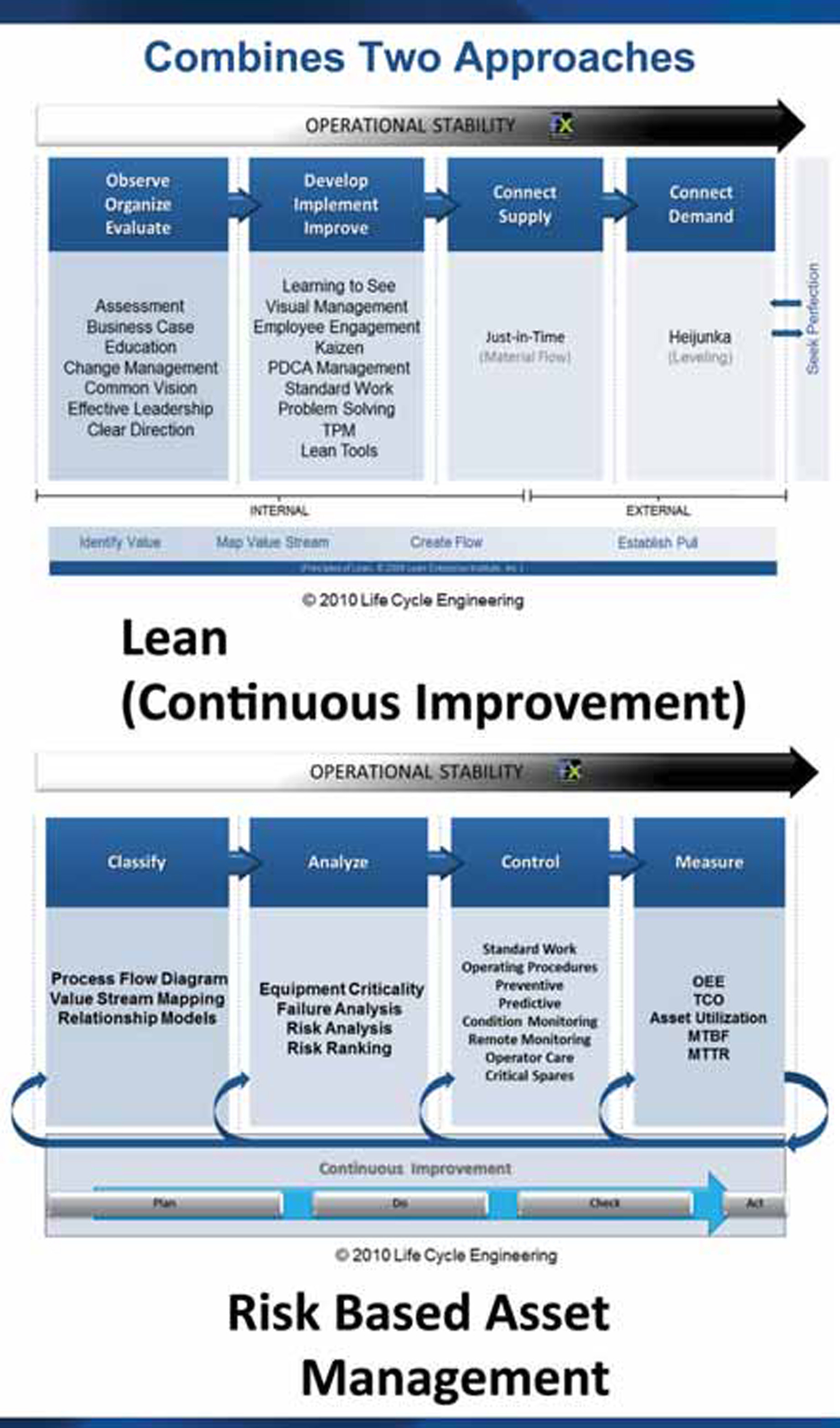

To improve under the LCE system, miners have to understand and identify losses. They have to participate in a problem-solving exercise to determine a root cause. After that, it’s a matter of finding the tools, setting priorities and developing an action plan. “We have combined Lean thinking with risk-based asset management,” Wesner said. “Lean is all about eliminating waste throughout a process. So we create a value stream map that starts outside the mine at the mill and then works its way back to the development heading.”

Thinking beyond a process flowchart, the value stream map plots the major mining processes and then incorporates the communications and various handoffs, along with inventory, feeding departments, etc. “We try to identify the constraints on the value stream,” Wesner said. “It could be poor performing assets. It could also be softer elements, such as shaft scheduling to get the right materials to the right place at the right time. Instead of coordinating how the shaft operates on a 24-hour basis, some organizations look at the shaft as a system that is there for anyone to use anytime. We try to put structure to these processes to better support the business.”

As the company’s name implies, they tend to concentrate on the life of an asset. “If we find we have poor performing assets or assets with a lot of losses, we will focus on that,” Wesner said. “We want the lowest total cost of ownership [TCO] and maximize total cost of operation. Understanding how an asset is being operated is also important. Problems might relate to how the equipment was originally designed. If a mine invested in inexpensive equipment, asset performance will probably not be as good as expected.”

For mine managers and engineers, getting their minds around technical improvements to equipment and process is relatively easy; engaging the people is where many struggle. “A mining company can make all of the technical changes it wants, but if it does not get the people involved, the program will likely fail,” Wesner said. He refers to the people aspect of the LCE program as the “secret sauce.”

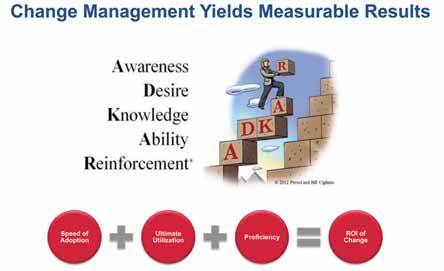

LCE reviewed many change methodologies before it found Prosci. Ironically, Prosci is not a change organization; it’s a surveying organization, Wesner explained. The company surveyed 2,000 organizations that successfully completed major management change initiatives. They used the data to create a methodology that looks at an organization through an ADKAR approach, one that creates Awareness and Desire, imparts Knowledge, gives the Ability to succeed, and offers a means of Reinforcement, as far as measuring the success.

The People Side of Change

Once managers become familiar with the

ADKAR theory, they can readily determine points of resistance, Wesner

explained. “Change starts with the individual and an important part of change is

communication,” Wesner said. “Preparing for change, managing change, and

reinforcing change are how an organization succeeds. A communications plan is

essential to create awareness and desire

for the change.”

Citing a recent conversation with a plant manager, Wesner asked if they had a communications plan. The plant manager said: Yes, we do. We have our quarterly meeting and I tell them the plan. “That’s communication, but not necessarily effective communication,” Wesner said. “A good communications plan relies on several approaches: town hall meetings, oneon-one conversations, toolbox talks, newspaper articles, email blasts, etc.”

Management also needs feedback. Leadership at the mine has to ask if the audience understood the message.

Prosci’s ADKAR program generates five outputs: a communications plan, a coaching plan, a training plan, sponsor roadmap, and a resistance management plan. “Many times a mining company will get ready to make a change,” Wesner said. “They know where the problems lie, but they refuse to formally address that sponsor issue or that resistance point in the organization.”

A formal resistance road map illustrates points of resistance. LCE paints people in the process as red, yellow and green. “Resistors are red; red doesn’t mean they are bad, they are just resistors,” Wesner said. “They have been doing it their way for a long time. They haven’t seen what it could be. It doesn’t mean they have to go away or be eliminated. They just need to be educated, trained or coached on the value to them.”

Wesner explained that every person needs to know what’s in it for me (WIIFM). “We have to create that WIIFM for everyone in the organization to get them to adopt this change,” Wesner said. “Once we have the road map with the reds, yellows, greens, we understand resistance points. Then we can design a resistance management plan.”

The LCE plan spends much more time on the people side of the equation than more tactical elements of the change. “If you invest 70% of the time on the people side, technical implementation will be adopted more quickly,” Wesner said. “A coaching and training program addresses the reds and yellows. Sometimes the yellows can be more of an issue than the reds. They are sitting on the fence. They are not sure which way they want to go.”

Companies that implement a continuous improvement program can measure success by a return on investment (RoI). The RoI might be measured by profit, increased tonnage or improved safety statistics. What affects the RoI is the speed of adoption, utilization and proficiency.

Wesner refers to the speed of adoption as the valley of despair. “The faster the mine gets through that period, the higher the RoI. “As the miners take ownership and become more proficient with the plan, the RoI only increases.”

Miners need to visualize a plan before they can embrace it. For this aspect of the training, Wesner turns to A3 Thinking, which is based on Toyota’s one-page production management plans. An A3 piece of paper measures 11- x 17-in. The plan is broken into five key areas: background, what is it we are going to do and why; current situation; future conditions, what do we want it to be; the action plan, projects to address the constraints; and key performance indicators, more production, increased profits, etc.

An A3 plan needs to remain simple, Wesner said. “We need people taking ownership from the beginning and they need a simple tool that they can easily reference,” Wesner said. “Many organizations have ongoing projects that could be incorporated into an A3 document. You don’t want a 100, but you could have 10. A good strategy is to have a queue and, as one project is completed, the next one is ready to launch.”

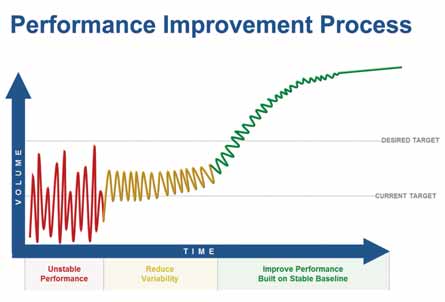

The performance improvement process should eliminate unstable performance and reduce variability. “We have to manage the noise at the beginning and get the process under control,” Wesner said.

Wesner recently completed performance improvement programs at two largescale mining projects. “When we first discussed our system, there was immediate pushback with the mining company explaining that it had previously participated in performance improvement efforts before,” Wesner said. “Afterward, they admitted they have never done anything like this and never achieved this level of performance.”

Case Studies

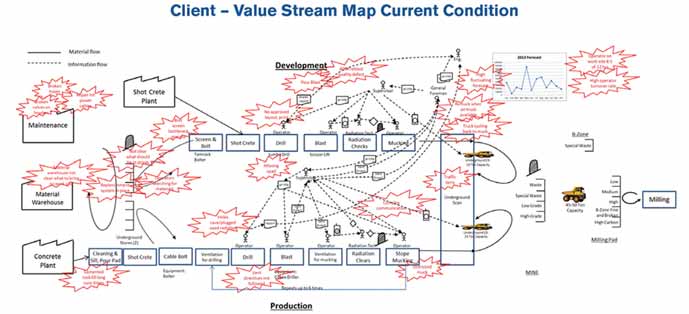

At an underground hard-rock operation in

Canada, the milling side was running at

40%. It was starved for ore. The mine

was able to blast three times per day.

Could they get to four or five blasts per

day? Wesner spent about two weeks mapping the underground production process

to build the value stream. “We started

where the milling process begins and

worked our way backward,” Wesner said.

“We mapped everything.” Ore extraction

involved two separate processes: development and production. The dark lines

represent material flow and the dotted

lines represent information flow. At the

end of the value stream exercise, they

had created a spaghetti chart.

Several red stars can be seen on the current state value stream especially for information communication on the development side. Wesner refers to these red stars as angry clouds, which represent non-value added activity. “These were opportunities for us to address,” Wesner said. The angry clouds include searching for materials, waiting for materials, complex materials movements, not having materials at the right place at the right time.

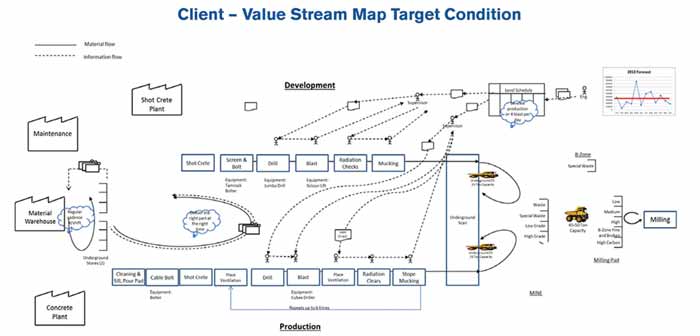

Then they designed a chart of what they thought the process would look like in a perfect world. “We needed to eliminate a lot of that spaghetti, but we had to be careful,” Wesner said. “This is underground mining and there is a lot of risk. It’s dangerous and bad things can happen. As we redefine or redesign the processes, we do not want to introduce more risk into the operation.”

LCE looked specifically at improving communications, which has nothing to do with the actual mining process. It’s simply information flow between the various steps.

On an underground walk-through, Wesner asked: Does everybody have the tools they need when they need them? The answer from the manager was: Absolutely. During a raise borer move, he asked to see the toolbox. The miners had a big empty toolbox. “Tools were scattered everywhere,” Wesner said. “That’s ineffective and it relates to ownership issues, primarily cultural and behavioral issues. The miners needed to put the tools away so that when the next crew arrived they could get to work straight away. This is basic blocking and tackling.”

The mine was able to eventually blast four times per day. Reaching that level of production represented a $15 million bottom line impact. “They couldn’t see themselves accomplishing this goal, because they could not visualize their value stream,” Wesner said.

Another mine was unable to meet the production plan for the year. The problem revolved around the raise boring process and the effectiveness of having the right tools in place. After looking at the value stream, they focused on shaft efficiency as far as getting materials to the right place at the right time. Because mining was a drift-and-fill process, they had to back-fill drifts before they could move to other parts of the ore body. That was a restraint.

Four or five projects were identified to improve mine performance. As an example, they wanted to complete a drift and fill in 14 days, but it always seemed to take them 28 days. After mapping it out on paper, they developed a playbook that said they could do it in 14 days. “They began to execute according to the playbook and they completed the process in 12 days,” Wesner said. “Moving from 28 days to 12 days was a significant gain in accessing more ore. That had a $255 million impact to the bottom line and they met their production numbers by just stepping back and looking at the process from the outside.”

Wesner is quick to point out that nothing that has been covered here is new. These techniques have been around for 15 to 20 years. “We are just trying to bring them together,” Wesner said. “When we did these projects, we didn’t ask the engineering teams or leadership teams to implement the plans. We went to the miners doing the work and got them to take ownership. Afterward, what we heard from the miners was: We wanted to help, but we were never asked.”

These results came from engaging the organization in a different way. It still requires active and visible leadership to celebrate the small victories. That’s where the company builds positive momentum.