Last month (May 2014, pp.66-71), E&MJ

looked at some of the major suppliers of

screens and screen media, with specialties

ranging from dewatering in coal washeries

to aggregate production, scalping and trash

capture in carbon-in-leach (CIP) plants.

Operators clearly have a large number of

choices, with some manufacturers offering

packages of both the screen hardware and

the media to go with it, while others specialize in the development of media that

can be fitted to other companies’ screens.

As a follow-up to that, E&MJasked a

number of industry experts for their views

on developments that have taken place in

screen media over the past five to 10 years.

The questions covered topics such as the

materials now available for different applications, the design of screen media, and

problems that they commonly encounter in connection with the incorrect

use of media on screening plants. They

were also asked for their advice on how

screening costs can be reduced, as well as

their predictions about screen-media developments and usage trends in the future.

A Question of Materials

E&MJ’s first question concerned developments over the past five to 10 years in

the materials used in screen media, and

their durability.

Derrick Corp.’s sales manager for North

America, David Perkins, told E&MJthat

the company has continued its quest to

produce the finest, long-lasting screen

panels in the world. Derrick uses its own

proprietary blends of urethane materials

to achieve a panel that is robust, while

maintaining the highest open area available, he said, noting that in 2013, Derrick

produced its finest urethane panel yet at

45 µm (325 mesh).

According to Sandvik,over the past 10

years, it has developed a complete range of

screening media, encompassing modular,

reinforced and tensioned panels. In applications with high abrasion, such as hard

rock and metalliferous ores, it recommends

the use of a high wear-resistant rubber,

with the flexibility of the rubber being chosen based on the separation and application criteria. Separation at smaller sizes

requires more flexible rubber, while heavyduty applications (coarse materials and

larger separations) require stiffer media.

The quality of the rubber is key, with each

product needing a high-performance rubber with outstanding mechanical properties, the company said.

Jeff Easton, a principal process engineer

at WesTech Engineering,told E&MJthat

since the mid-2000s, the company has put

significant effort into improving its specialty screening products such as its media

retention screens. Adsorption carbon as well

as newer synthetic resins must be retained

in a leach vessel by the inter-stage screen

while at the same time allowing the mineral slurry to pass through, he explained.

“Wear on the screen media can be

significant, impacting not only longevity

but also consistency in the retention aperture over time as well,” he said. “WesTech

has combatted these challenges by utilizing a high wear-characteristic alloy and

steeper wire wedge angle, allowing its

screens to not only resist wear, but also

maintain an appropriate aperture range

ensuring less loss of near-size valueloaded carbon or resin.”

Speaking for the Canadian company,

Major Wire Industries,President and CEO

Jean Leblond said that high-performance,

self-cleaning screen media using

polyurethane strips have been achieving

increasing market awareness, replacing

woven wire on the one hand and polyurethane or rubber on the other. The company’s Flex-Mat 3 eliminates virtually any

blinding and pegging, he said, and accelerates stratification due to its independently vibrating wires. “It lasts between

three and seven times as long as woven wire, giving up to 50% more higher-quality

production,” Leblond said, adding that

Flex-Mat 3 produces up to twice as much

as polyurethane or rubber media for users

looking for more tons per hour.

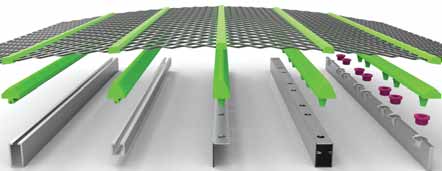

FLSmidth’s screening experts point out that the company’s use of high-quality spring-steel frames allows

FLSmidth’s screening experts point out that the company’s use of high-quality spring-steel frames allows

modular screen media to achieve a much higher ‘open area’ while reducing the installed mass.

Les Naday, mining industry manager

for Polydeck Screen Corp.,said there has

been some improvement in wear resistance

and durability because of new formulations

that have become available for rubber and

polyurethanes. These formulations have

proved to be beneficial in specific cases,

he said, emphasizing the way in which

manufacturers can now tailor their screen

media products to meet individual operations’ requirements.

For FLSmidth,the company’s general

manager for screen media, David Sibley,

also pointed out that while investigation

into improved materials for the manufacture of polyurethane screen panels is ongoing, none of the many materials tested in

the last few years has demonstrated qualities over and above the material currently

in use. In addition, the use of high-quality spring-steel frames has enabled modular

screen media to achieve a much higher

“open area,” with percentages of up to

55%, while reducing the installed mass.

The company has also introduced

hybrid modular polyurethane panels using

different types of screen media such as

wire screens, perforated material and

wedge wire to bring different characteristics to modular screening.

Screening specialist for Tenova Delkor,

Rhett McElvenny, looked at materials used

in linear belt screens. “The screening

medium used for the linear belt screens

has historically been a woven polyester

mono-mono construction,” he said. “Some

duties can use polypropylene cloths.

However, these pose tracking problems,

particularly on larger machines. Some

duties may also use metal link mesh as the

screening medium, but these are quite

specific to a particular duty.”

Screen Media Design

Having asked the experts about screen

media developments, E&MJextended this

to the design of screening media. Have

there been any noticeable changes in this

area, such as the wider use of modular

designs?

Naday(Polydeck): Modular media has

taken hold in mining applications, allowing

the mixing of various duties to meet maintenance cycles. Most large mines take

advantage of modular panels’ flexibility

as well as their safe and easy installation

and removal.

LeBlond (Major Wire): Around the

world, large mining operations use polyurethane or rubber while smaller operations are largely using woven wire.

Easton(WesTech): “Specialty screening

products differ significantly from traditional vibrating products in that the material

being screened does not necessarily have

to move across the screen surface. This

opens a much wider range of possible

materials and configurations that can be

used for screening media.

Weir Minerals’ Armor polyurethane wire screen media

offers

Weir Minerals’ Armor polyurethane wire screen media

offers

the combination of high-grade wire cloth with a

molded

coating of premium polyurethane.

“For example, WesTech’s linear screen

utilizes a moving belt of screen fabric with

flexible roving, allowing the media to wrap

around return drums. The fact that the

media moves to the discharge eliminates

the need for the material itself to slide and

wear on the media surface. This configuration also allows for easy cleaning of the

media in the return cycle, eliminating pegging and plugging issues.”

Sandvik: More and more customers are

realizing the benefits of modular media:

easy to handle, fast installation and moulded holes with a relief angle. This prevents

problems with pegging.

McElvenney (Tenova Delkor): The

media have not changed greatly; the medium is a woven cloth and the aperture determines the cloth model used. “Tenova

Delkor has increased the size of the actual

screening device in the past five years from

25-m2units to 32 m2

and more recently,

to a 40-m

2

machine,” he said.

Perkins(Derrick): The company is committed to manufacturing urethane panels

for exclusive use on screening machines

designed and manufactured by ourselves.

There is a strong relationship between the

performance of the panel and the machine

it is installed on. “We believe that this is

truly a situation where one-plus-one is

greater than two, so to speak.”

Sibley(FLSmidth): “In most new process

plants, screening machines are being sized

according to the open area and use of modular screen panels. Further to this, we have

developed and supplied our BPS (Bolted Pin

System) polyurethane modular screen panels, where the unique design gives a superior open area and reduced installed mass of

the panels on the screen decks.”

The advantage of a higher open area

and lower installed mass adds to the

screening efficiency and the effective consumption and use of input energy. In addition, the BPS panel-fixing method has

proved to be user-friendly for plant maintenance staff, with less plant downtime for

routine deck replacement, Sibley said.

Common Screening Problems

E&MJ next asked each of the respondents

about any specific problems they see on a

regular basis that arise from operators not

using appropriate screening practice.

Sandvik:It is important to take the

whole process into consideration when

problems occur on a screen. Sometimes

there is a lack of process knowledge, and

adjustments are done on the screening

media instead of maybe making changes at

the crusher settings, chutes or feeders.

When a screen is not performing, it is

important to really understand the underlying reason for the problem. An example

might be if there is a problem with throughput, where material is not being screened

out and just keeps recirculating. Having the

knowledge to do a proper study to identify

the real problem is key here.

Polydeck says its modular panels are easy to place and

Polydeck says its modular panels are easy to place and

remove, but they—like all modular products—must be

installed correctly for maximum effectiveness.

Even if the problem is shown to be on

the screen, the actual cause might be

somewhere else. Just making changes to

the screening media when it comes to hole

sizes and thickness could lead to an endless road of changes that don’t really solve

the problem. The cause of the poor screening might instead be non-optimal screen settings, where changes to the speed or

stroke could provide the solution.

Another common problem is uneven loading over the width of the screen, or feed segregation, in which case changes to the feeding arrangement is the solution. It is also

important to remember that making adjustments to the crusher may also help. In reality, there is often very limited benefit in changing the properties of the screening media

before the feeding arrangements and screen

settings have been optimized. Our teams

often run into “screening problems” that

have other causes than the screening media.

Perkins:“Performance problems arise

from improper installation of the panels on

the machines. Derrick is developing mechanisms that mitigate this problem.

However, with such a large installed base

worldwide of older technology, coupled

with the long life of the machines, this is

an ongoing training hurdle for the natural

turn-over experienced by most operators.”

McElvenney:“The most common problem that we see is screens being fed with

too much coarse material as a result of mill

discharge cyclones being overloaded and

‘roping.’ This results in the screen receiving slugs of coarse material and subsequently flooding.”

Leblond: “A large percentage of the

woven wire media in use break because of

poor installation that is itself a result of a

lack of know-how on proper practice. Since

2008, Major Wire and its authorized dealers

have given a simplified screen maintenance

seminar to more than 6,000 operators to

teach best practice in the installation of tensioned screen media on shaker screens.”

Naday:While modular panels are simple and easy to install and remove, difficulties caused by untrained contractors

doing maintenance are seen. Sometimes

panels are left in operation after they have

failed, causing costly repairs, and sometimes the installation is done incorrectly.

Easton:The greatest difficulties arise

when particular screening technologies are

misapplied. For example, using a highenergy vibratory screen on material that is

very friable can cause significant attrition

and particle-size degradation, leading to

losses as well as plugging. Often in mineral applications, the need to classify material by particle size is superseded by the

need to classify on particle density. If size

classification techniques are attempted

when both size and density classification

are required, the results can be disastrous.

Sibley:“Over a long period, we have

observed that screening machines are not

correctly maintained or setup for the

screening duty they are being utilized for.

We frequently find that the amplitude and

speed are not appropriate to the cut size,

and the ‘g’-forces are incorrect for effective

stratification and screening efficiency.

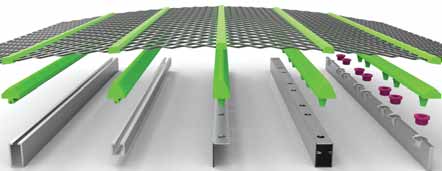

Major Wire developed its line of crown bar adaptors, pictured here, to help producers who had flat screen

Major Wire developed its line of crown bar adaptors, pictured here, to help producers who had flat screen

decks

that were limited to only using modular type screen media but wanted to use Major Wire’s

Flex-Mat 3 tensioned

high-performance screen media.

“This can result in shorter screen life

from the abrasion caused by deeper bed depths. In addition, poor screening efficiency can lead to higher recirculating

loads. This in turn can have the effect of

increasing the cost per ton in downstream

equipment, such as higher wear rates of

crusher manganese and the over-generation of fines in the product.

“As far as spillage is concerned, poor

housekeeping and inappropriate maintenance are health and safety risks. They

also push up the cost per ton, but can be

corrected with proper plant management.

The old saying of ‘penny wise, pound foolish’ springs to mind, with the main emphasis being placed on initial cost rather than

the cost per ton. Disregarding the overall

importance of any screen media used in a

process also has a negative impact on

achieving the lowest cost per ton.”

Cutting Screening Costs

Here, the respondents gave their views on

the measures that operators can take to

reduce screening costs within the overall

cost of mineral processing.

Sandvik:Make a close study of the

process, ensuring to really get what is

being aimed for. It might be better overall

economy to produce a smaller tonnage of

higher-quality material than a higher total

tonnage at lower quality. It is most important to fully know and understand the

process. Study the screens very closely; in

general, there is a lot of focus on crushers,

but screens are allowed to run with very

little attention—unless problems occur.

Having large amounts of unscreened final

product will only cause high circulating

loads in the process, so causing unnecessary wear on all the other equipment

involved.

Naday:Screens do not get the respect

given to more costly equipment, even

though screening is a critical part of the

process that can cause exorbitant costs in

other equipment. A screening expert can

determine and recommend the optimal

parameters for an operator’s specific conditions. Questions to ask include: Is the

screen running at the correct speed? Is the

media performing its metallurgical duty? Is

the media maintenance fine-tuned to the

plant maintenance cycle? Are fines adequately removed from the circuit?

McElvenney:As a belt linear screen

receives and cleans a considerable slurry

flow, it is imperative that it is regularly

maintained to ensure free roller movement,

which in turn reduces stresses applied to

the screening cloths. Flood detection sensors also reduce flood events.

Sibley:As noted above, the cost per ton

can be improved with appropriate management. To assist this process, plant surveys will identify problem areas where the plant

is not performing adequately or according

to its original design. Based on the survey,

corrective action can be planned with the

incorporation of the latest technologies

where appropriate.

Easton:A firm understanding of the

classification requirements in a particular

application are the best starting tools an

engineer or operator can use. Recognizing

what the process requirements and constraints are, and reconciling those with

equipment solutions, is critical. Having the

right screening and classifying equipment

to achieve the desired process at the best

combination of capex and opex will ensure

the highest return on investment.

Derrick Corp. uses its proprietary blends of urethane materials to achieve a panel that is robust, while

Derrick Corp. uses its proprietary blends of urethane materials to achieve a panel that is robust, while

maintaining the highest open area available. In 2013, Derrick produced its finest urethane panel yet at

45 µm (325 mesh).

Leblond:The answer to this question

varies depending on whether tensioned

media or modular panels are being used on

shaker screens. Looking specifically at tensioned-wire media, either woven or FlexMat 3, the media should wear and not

break. Operators should know how to install

screen media so as to eliminate breakage.

Perkins:“The single largest contributor currently to reducing operating costs

within mineral processing is the application of the Derrick Stack Sizer. Derrick’s

application engineers are enabling concentrators to drastically reduce grinding

costs through the use of fine screening to

replace more traditional separation

devices like hydrocyclones.”

Future Trends

Finally, E&MJ asked the experts how

they see screening practice developing,

especially in terms of screen media design and properties.

Easton: “Continued development of

materials of construction as well as configurations will inevitably improve valuable

material recovery. Thinking outside of the

box is key to finding better ways of classifying and screening. Just because this is

how it always has been done is no longer a

valid selection criteria. Undoubtedly there

will be those who stick with ‘if it ain’t

broke, don’t fix it,’ but rest assured soon

they may be left in the dust by those interested in finding a better way.”

Sandvik:More advanced products are

to come, both regarding material and

design. Customers are requesting longer

lifetimes combined with high efficiency.

That will not be solved just by using thicker media; it has to be something else.

Leblond:“I see Flex-Mat 3 replacing

75% of the woven-wire screen media and 25% of the polyurethane or rubber media,

around the world.”

Naday:More and more focus on the balance between screens and the surrounding

equipment is being seen. Attention is needed to producing screen media with large

open areas, to material blends, and especially to consistently reproduce modular

screen media for maintenance planning

and consistent availability.

Sibley:The industry is constantly on

the lookout for methods to improve existing

processes and to develop new processes for

products. It follows that as these innovations are implemented, new screening

technologies may be needed, so existing

screen media will need to be examined and

modified to complement any innovations.

Weir Minerals’global product manager

for screen and screen media products, Kurt

O’Bryan,sees a potential trend developing

with some customers, where wire screen

media could be an option. “Customers are

starting to question what kind of media

they are using. Some are considering

switching from urethane back to wire,

increasing efficiency in spite of higher

maintenance requirements,” he said.

“Adding value to plant design and operation will become recognized as a new area

of development in the near future. Special

knowledge and experience with regard to

screen media and its application should be

considered in the initial stages of plant

design, and acted on positively to ensure

that when installed, all the criteria affecting

the screen media are taken into account so

as to maximize the process efficiency.”