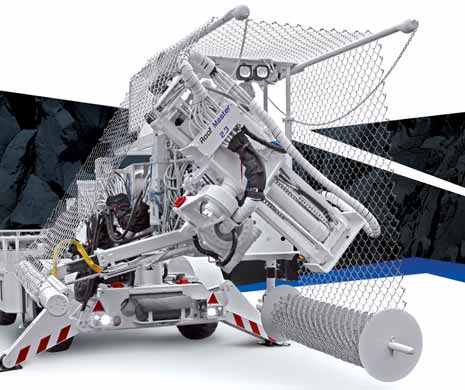

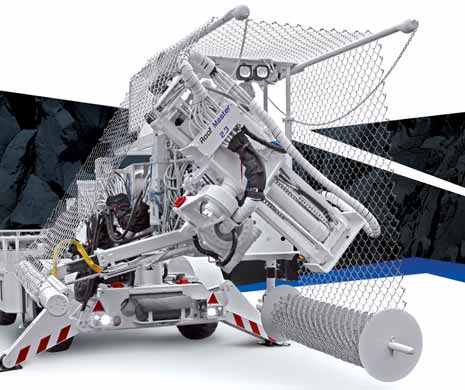

New Roof Bolter Targets Chilean Mines

The new Roof Master 2.3 bolter emerged from a cooperative effort involving Mine Master, J.H Fletcher, HRI and the end user, Chilean copper producer Codelco. Its design allows the entire roof support process to be carried out by one machine in three steps: 1) drilling of bolt holes, 2) lining both side walls and roof with wire mesh (carried onboard in rolls) and 3) installing and cementing grouted bolts. This approach, according to Mine Master, offers significant reductions in time and cost along with operator safety improvements.

The bolter’s major features include:

• A J.H. Fletcher rotary percussive rock

drill that can be operated from the bolting stand or from the cab.

• CAN-BUS system and an ergonomic, airconditioned cabin.

• A roof-referenced mast, to drill bolt holes

in one step, up to 2.5 m in depth.

• Cement mixer with pump.

• A patented mesh handling system that

uses mesh rolls.

• “Inch” tramming that allows the rig to

easily move from one row to another in

simple, quick sequence.

• Range to conduct bolting in headings

sized from 4 x 4 m to 7 x 7 m.

Up until now, said Mine Master, roof support operations required three machines and four steps (drill with telescopic feeder, position forklift mast and cement mixer to install cement grouted bolts, followed again later by the forklift mast to install mesh) requiring nine workers. Total work time was typically more than 10 hours, with at least a five-hour delay for cement curing.

With the new Roof Master 2.3 rig, the entire procedure can be performed with just one machine and two workers (operator and helper), reducing total work time to less than three hours. The principal advantage, according to the company, comes from the use of cement-grouted mechanical anchor bolts with expansion heads allowing for immediate installation of mesh, thus saving significant time.

The rig will be displayed at the HRI S.A. stand—Mine Master’s distributor in Chile— and visitors will be able to view a simulation of the rig working in a tunnel.