Looking ahead over the next five years, a recent survey indicates that mining executives believe investment in digital

technology will improve company productivity and play a major role in reorganizing operations. (Photo courtesy of Caterpillar)

Digital Tools for Mines Help Maintain a Competitive Edge

Many mining executives are convinced there’s really no alternative: either join the

industry’s quickening interest in digital technology or risk losing ground

By Russell A. Carter, Managing Editor

Recent survey results show that the industry realizes the demand for digital tools extends literally from its grassroots—exploration-data management—to daily operational and human-resource activities, and to the sophisticated enterprise resource planning (ERP) systems needed to make strategic business decisions. A company’s move toward higher operational efficiency based on effective use of data may no longer be defined, or confined, by what can be gained traveling the narrow lanes of a digital “highway.” In the future, it’s more likely to take the form of a digital immersion affecting almost every factor of mining activity, from the way projects are designed and managed to the tools and devices mine personnel will use—and wear—while on the job.

Surveys also indicate that many mining executives realize there’s really no alternative; either participate in the industry’s gradual embrace of digital technology or risk losing a competitive edge.

Maintaining an Edge

In North America, for example, miningsector corporate investment in digital technology has increased over the past three

years, and will continue to rise as companies seek to disrupt traditional business

models to maintain their competitive position, control costs and stay viable, according to an Accenture survey of mining executives in Canada and the United States.

One-quarter of mining executives surveyed by Accenture—a management consulting, technology services and outsourcing company—said their overall digital investment in the past three years has doubled or more. Almost all companies surveyed (93%) are satisfied with their digital investment and the associated business outcomes. In the next three years, 33% said they will significantly increase their digital investment, 63% will increase their spending modestly, while only 5% will keep spending the same. No companies surveyed are planning to cut back on digital investments in the next three years.

Nine out of 10 executives surveyed said a business strategy that incorporates digital technology will revolutionize the way they do business to a degree similar to the advent of the Internet in the 1990s, and will provide a significant source of value to the business. Companies that do not embrace digital will lose their competitive position and may face extinction, according to 88% of respondents.

“Now more than ever, North American metals and mining companies are turning to digital, a new frontier for metals and mining companies to improve operations, productivity and identify growth opportunities,” said Jose J. Suarez, managing director, mining (North America), at Accenture. “We know that mobility devices can be used to track maintenance and reliability—and provide miners with better status updates that result in faster decision-making. Also, with analytics and Big Data, the integration of resource modeling data and operation status can help metals and mining companies to better control operational costs.”

Even so, the survey shows there is more work to be done for digital adoption within the metals and mining sector. While some North American mining executives are investing in digital to gain a competitive advantage (58%), some said they are just trying to keep pace with their competitors (42%). Whether they are trying to stay ahead or keep pace with the competition, almost all mining executives surveyed (96%) are projecting an increase in their digital investment in the next three years. Three-quarters said they feel they are ahead of their peers when it comes to digital.

Currently, digital programs are driving strategic decision-making and commanding support from senior executives (83%), according to the Accenture survey. Four out of five executives surveyed are using digital technologies across IT, business operations, finance and human resources. Looking ahead to the next five years, mining executives believe digital will improve company productivity (73%), reorganize operations (65%) and optimize the supply chain (58%).

As they invest in digital technologies, metals and mining companies are hiring more digital talent (88%) and adopting new digital technologies (95%). When looking at overall company return on investment, analytics and Big Data are believed to hold the most potential (65%), followed by cloud (48%) and mobility (43%).

Accenture conducted the online survey in February, involving executives at 40 metals and mining companies from medium to large organizations across Canada and the U.S. The company said the survey’s margin of error is 12% with a 95% confidence interval.

Maintaining Control

Managing data has become a critical concern in the exploration community, according to a report released by Geosoft following a January 2013 survey.

When Geosoft conducted a similar survey in 2011, only 18% of respondents identified managing exploration data a matter of “critical importance.” Now, 44% of them do, with another 38% regarding it as a “top five issue.”

Geosoft, which provides software and services for visualizing and managing geoscientific data, said it collected information from 415 organizations around the globe. The 693 respondents represented a cross section of roles within resource and energy exploration companies, industry service providers, government, and educational institutions. More than 60% were from the mineral resources industry, with the remainder coming from energy (11%), government (9%), educational organizations (5%) and other sectors.

Some key findings:

• Organizations are shifting data out of

the hands of individuals and onto centralized servers. Forty percent of respondents now manage their drill-hole and

geological data on a centralized server

with a folder or file structure, while 51%

manage geophysical and other survey

data this way.

• Respondents want tighter control over

their exploration data and a more efficient workflow. About two out of three

would prefer a single commercially available platform or an in-house solution as

opposed to outsourcing their data management, hiring consultants, or allowing

users to manage their own data.

• Search tools, complicated workflows,

data duplication and dependency on

knowledge experts remain the biggest

obstacles to data management.

• Most organizations spend four to eight

hours on data management per week,

with some spending much longer.

• The two most important outcomes associated with better data management were

increased visibility and transparency for

reporting and attracting investors (38%)

and improved discovery rates (25%). Few

(7%) considered a quick return on investment to be the most important outcome.

Technical experts at Rio Tinto’s Processing Excellence Center in Brisbane can review, in real time, incoming data from copper processing at Oyu Tolgoi in

Mongolia and Rio Tinto Kennecott Utah Copper in the United States as well as five coal sites in Australia.

In summary, the report found that there is a growing need for effective data management in the exploration community in order to attract investors and improve discovery rates. Although organizations are getting better at centralizing their data on a single platform, more work needs to be done to increase data accessibility, reduce duplication, smooth workflows and lessen dependency on experts.

Software developers seem to understand

that many of the data-related problems cited

in the Geosoft survey are applicable to the

entire scope of mining, and beyond. For

example, to help drive greater collaboration

at mining operations and with off-site offices

and consultants, Dassault Systèmes GEOVIA

recently noted that its Surpac underground

mine design package and Minex coal geology and mine planning software are now

directly integrated with GEOVIA Hub and its

data-sharing capabilities. This ensures users

have access to the right data, so that:

• Project files are published into Hub, enabling users to easily verify they have the

most up-to-date data.

• Repetitive verifications on data are eliminated since version confusion no longer

exists.

• Auditing of a file’s version history shows

who made changes to it and when.

• Fast roll back to previous versions of data

is available if required.

• By facilitating simpler and more effective

means of sharing data on site or with remote locations, personal and cross-functional productivity and confidence in

data is increased.

GEOVIA noted that with underperforming mining assets impacting share prices,

mining CEOs are looking to improve financial returns and boost free cash flow by

driving growth through better management

across the mining value chain. By making

better and faster decisions from the rock

face to the port, processes can be made

more efficient, mineral resources used

more effectively, and wasteful practices

eliminated. The end result is a healthier

bottom line and increased sustainability.

The ability to meet those desired results, according to IBM and other suppliers of Big Data solutions, is to recognize that a company’s IT resources can be buried under mountains of data from continuously flowing streams of monitoring and metric data from networks, servers, storage, databases, mobile infrastructure, applications running in external and internal clouds, events and operation logs, to name just a few. In fact, it’s estimated that 90% of the data that exists in the world today has been created in just the past two years.

Based on the results from the Accenture survey, it appears that mining executives are willing to spend money on information technology to meet this problem, but whether the investment reaps all the prospective benefits expected, or even achieves basic project objectives, is not always assured.

Maintaining Excellence

One approach larger corporations are taking

to ensure their IT-related investment goals

will be achieved is through centers of excellence. According to The Hackett Group, a

global business consulting company, leading

businesses are increasingly implementing

centers of excellence as a means of efficiently and effectively managing specific

complex business tasks. Centers of excellence are teams of people with specialized

expertise who work together to develop and

promote best practices in their area of

responsibility. Centers of excellence may provide subject matter guidance to the rest of

the enterprise, or may deliver tangible business services. Examples of business tasks

around which centers of excellence may be

created include project management, quality

assurance, regulatory compliance, business

analysis, continuous process improvement,

and enterprise performance management.

The most recent example of this trend is Rio Tinto’s launch of its Processing Excellence Center (PEC) in Brisbane, Australia, the latest phase of its Mine of the Future technology and innovation program that, according to the company, is driving greater value by optimizing the performance of key international copper and coal operations. The Brisbane center, said Rio Tinto, is a world-first, state-of-the-art facility that enhances monitoring and operational performance by examining processing data from seven of its operations spread across the globe.

An expert mineral processing team operating out of the PEC shares technical initiatives and solutions to colleagues on mine sites in Mongolia, the United States and Australia about how to maximize productivity and improve performance.

With the aid of a giant interactive screen, technical data is monitored and analyzed in real time, allowing processing improvements to be immediately introduced and operational performance to be optimized. The company said a trial phase of the PEC has already led to various procedural enhancements, such as adjusting the flotation process, which increased the recovery of copper and gold at Oyu Tolgoi in Mongolia.

The PEC is also linked to copper processing at Rio Tinto’s Kennecott Utah copper operation in the United States, as well as five coal sites in Australia. Rio Tinto worked with JKTech, Schneider Electric, Metso CISA, iGATE and the University of Queensland through the Rio Tinto Center for Advanced Mineral Sorting to develop the PEC.

Among these partners, Metso CISA has developed a number of Advanced Process Control (APC) tools that include OCS and OCS-4D software with embedded expert system, fuzzy logic, modeling and optimizing modules, MPC, neural networks, vision and acoustics analysis algorithms. Among its more well-known systems are VisioRock for rock/particle size measurement, and VisioFroth, for flotation froth velocity control. These and other CISA systems have been used at some of the world’s largest mines, including Escondida in Chile and Antamina in Peru.

Schneider Electric said its services support the analytics for the center, and also provide regulatory control on instrumentation and data management for the seven mine sites.

Phil Barrett, Schneider’s global account director for Rio Tinto, said, “The PEC is really pushing the boundaries of technology in terms of communication architectures, virtual environments and remote connections. As a result, it has become a truly collaborative environment that centralizes many varied and complementary skills, leveraging the vast experience and expertise of its people, to work as one team delivering significant savings to Rio Tinto.”

Schneider also announced in February the release of StruxureWare for Mining, Minerals and Metals, a suite of applications aimed at optimizing production operations. The StruxureWare suite integrates process control, operations management and energy management to “allow customers to gain actionable insight into their entire operation,” according to the company, which noted that with the ability to manage and analyze data generated in real-time, customers are able to reduce operation costs and waste and increase safety.

According to Schneider, the suite can improve energy efficiency by combining energy and production data to allow operations and energy managers to work together to optimize operational demands and energy and water consumption to reduce costs. In addition, it provides visibility into enterprise and supply chain performance and analyzes results over time to identify areas for improvement.

The StruxureWare mining suite consists of:

• Resource Advisor: tracks and manages

energy and carbon costs;

• Energy Operation: transforms data into

essential energy information;

• Plant Operation: combines energy and

process data for visibility into asset

performance;

• Supply Chain Operation: optimizes the

supply chain;

• Power Monitoring Expert: collects and

organizes data from the electrical network;

• PowerSCADA Expert: manages the

power network based on telemetry systems that transform data into useful

information; and

• Process Expert: integrates application

control and supervision into a single

environment.

Maintaining Machine

Productivity

As an example of a solution focused on a

somewhat smaller-scale application—but

with important implications for producers

of all sizes—IBM announced in February a

new collaboration with Thiess, one of the

world’s largest contract miners, to use Big

Data to improve machine availability and

operational productivity utilizing predictive

analytics and modeling technologies. This

initial collaboration focuses on Thiess’ haul

trucks and excavators to help unify asset

management and business operations.

Many fleet operators still rely heavily on either a “fix-it-when-it-breaks” approach or time-based scheduled maintenance techniques. These methods often result in unnecessary downtime, premature component replacements, extra expense and lost production. They also do not explicitly factor in an individual piece of equipment’s actual condition and performance capability.

However, this trend is changing. Increased deployment of machine and environmental sensors combined with new data collection methods is enabling the development of predictive machine maintenance analytics, which can help increase equipment availability, lower production costs and provide greater operational flexibility.

The IBM and Thiess collaboration integrates current and historical machine sensor data, along with maintenance and repair, operational, and environmental data to use as a basis for data-driven operational optimization. Factors such as repair and inspection history, payload size, sensorbased component alerts, operator variability, weather, and ground conditions are being used to construct models, which assess and predict the life of discrete components and the overall health of a piece of equipment. This information will enable decision makers to co-optimize maintenance and production decisions, resulting in better operational performance.

“Analytics and modeling can offer great opportunities to improve our business, but we need to integrate them with our current processes in order to have a real bottomline impact. Working with IBM to build a platform that feeds the models with the data we collect and then presents decision support information to our team in the field will allow us to increase machine reliability, lower energy costs and emissions, and improve the overall efficiency and effectiveness of our business,” said Michael Wright, executive general manager– Australian mining, at Thiess.

Early detection of even minor anomaly and malfunction patterns can be used to predict the likelihood of component failures and other areas of risk. This will dramatically increase the uptime of the equipment and improve Thiess’ ability to manage the full life of discrete components, overall machine health and the deployment of limited maintenance resources.

Matthew Denesuk, manager of Smarter Planet Modeling and Analytics at IBM Research, said, “By combining knowledge of the physical health of the equipment with information about how it needs to be used, we are able to know when something is going to go wrong and what can be done to fix the root problem before that occurs.”

IBM said developing a unified predictive equipment and operational management system requires finding common connection between physical and computer scientists, who often operate with different skill sets and goals. The models used in this project bring together the physical and digital worlds by supplementing datadriven modeling that computer scientists tend to employ with information from engineers who have first-hand expertise about the mechanics of the equipment.

Predictive machine management bases decisions about a machine’s maintenance and operation on the actual condition or health at that given time. It also has the ability to predict the health of a given machine far enough in the future to enable decision makers to execute correct actions such as adjusting production plans or ordering spare parts.

As an example, IBM posited a mining scenario in which several haul trucks may be reported to need maintenance, while at the same time a substantial order of product is due for delivery in 11 days. The predictive machine management system will be able to look at a variety of options for addressing this problem, and provide a decision maker with a model-based prediction that if the trucks are loaded no more than 85% of normal capacity and driven at no more than 80% of normal speed, the failure probability over the next 11 days would be minimal. This allows companies to avoid costly downtime at the sacrifice of only a minor, temporary decrease in throughput.

Business analytics is also at the heart of MineSight Performance Manager software, released in 2013 by Mintec. “MineSight Performance Manager is designed to fill a need for coordinated, actionable reporting, analytics and decision support at mine sites,” said Mintec President John Davies. “Right now, this need is largely being filled by spreadsheets at many sites. Data for those spreadsheets is often cobbled together from multiple third-party sources, a time-consuming process, which brings with it the risk of error and misunderstanding.”

Mintec said the launch of Performance Manager builds on the functionality of MineSight Axis. Operators use MineSight Axis for real-time reporting of production data and dynamic design of blast patterns. MineSight Performance Manager adds improved data integration tools and a focus on business intelligence and analytics via dashboards that offer streamlined displays. It supports data gathered with MineSight Axis Drill and Blast tools, and according to Mintec, includes model-tomodel reconciliation, fleet management system production data to model reconciliation, and mill to model reconciliation with data gathered by the MineSight Axis Grade Control tools.

Maintaining Mobility

Although getting control of the Big Data

dilemma is likely a primary concern in corporate executive suites, rapidly advancing

mobile digital technology offers an avenue

for getting appropriate data and interactive

capabilities to personnel on the ground.

MicroStrategy Inc., a provider of enterprise software platforms, announced earlier this year that Kinross Gold Corp. has deployed an iPad application using MicroStrategy Mobile for its global mining operations. Kinross, the fifth largest gold producer in the world, has mines and projects in Brazil, Canada, Chile, Ghana, Mauritania, Russia and the United States.

MicroStrategy said Kinross sought a mobile solution that could address its diverse workforce, provide near real-time feedback on mining operations, and give regional supervisors the ability to input data directly from the mines without the need for PCs. According to Alexis Ricordi, director of project management, Kinross’ analysis of the available analytics vendors included considerations for platform speed, ease of use, mobile functionality, speed to development, and total cost of ownership.

Kinross has taken the approach to develop once and deploy everywhere. “When developing dashboards at Kinross, we make sure that we design them to run on PCs as well as on mobile equipment,” said Ricordi. “One of the biggest advantages of MicroStrategy is that we can develop them once and they can be available to the users on multiple platforms.”

MicroStrategy said having a mobile application has benefited Kinross’ fleet management supervisors. The Kinross iPad application is used across multiple sites in different countries, and automatically changes based on the language needed. Additionally, with transaction services, the supervisors are able to input data directly from the field, which speeds up decision-making.

Last year, MicroStrategy conducted a survey on dashboard use among a diverse group of participants. Predictably, 78% of respondents said they would prefer to access their dashboards via a mobile device. In fact, mobile dashboard delivery was ranked as the most preferred method for receiving, viewing and interacting with dashboards. Yet, only 28% of respondents have mobilized dashboards; the majority still use desktop machines. Despite the rise of self-service analytics and the increased adoption of mobile devices at large enterprises, users at most organizations remain tethered to desktop machines for their analytics.

MicroStrategy maintains that today’s users are accustomed to on-the-go information in their personal lives, so it no longer makes sense to expect them to be restricted to a desktop. Having analytics deployed as a native app on smartphones or tablets not only allows for mobility, said the company, but it also enhances the capabilities of information-driven apps by making full use of all of the sensor inputs available on mobile devices.

It’s a trend that seems to be gathering momentum, with many major industry vendors offering mobile apps that provide product catalogs, dealer contact information and more. A good example is Caterpillar’s Product Link, a remote monitoring and asset management solution, and its VisionLink interface, which the company says makes it easy for a manager to monitor data from a whole fleet and then zoom in for a detailed look at individual assets.

Fleet managers’ ability to monitor equipment remotely has been improved with the latest release of VisionLink, providing customers with a mobile optimized Web application, the ability to schedule automated delivery of VisionLink reports, and remote access to on-board payload system information.

The mobile application is available on iOS, BlackBerry, Android/Chrome and Windows operating systems. Introductory functionality enables viewing the location of assets on a map, tracking scheduled services, viewing fault codes and open alerts, and accessing idle, working and runtime data through a smartphone.

New productivity functionality leverages existing onboard payload systems for wheel loaders and off-highway trucks equipped with such systems. Managers can remotely monitor information such as total payload moved per day and total payload per hour and per unit of fuel.

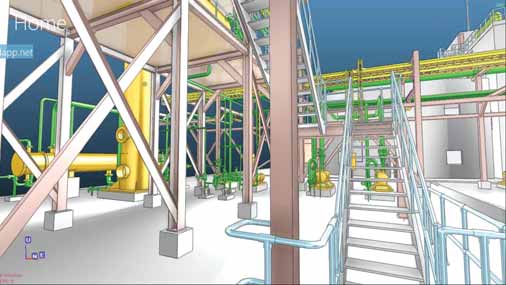

On the stationary-asset side, AVEVA, which provides engineering design and information management solutions for several industrial sectors, announced that its Everything3D (E3D) Insight application is now commercially available for project managers in the mining industry. This Windows 8.1 app enables mobile users to comment and approve E3D designs from a tablet device. Developed in collaboration with Microsoft, it provides the ability to inspect, comment upon, and approve designs at any time, from anywhere around the world, according to the company.

“Over the years, we have seen how many companies struggle to effectively collaborate across their supply chain,” said Bruce Douglas, senior vice president— product strategy and marketing at AVEVA. “AVEVA E3D Insight overcomes this challenge by providing an innovative and intuitive mobile platform on touch-enabled tablets and laptops connecting directly to the design model and its community of designers. The improved reach and efficiency of collaboration that AVEVA E3D Insight brings is an important component of AVEVA’s revolutionary Design for Lean Construction initiative. Initial feedback from customer evaluations, including WorleyParsons and Technip, as well as user meetings has demonstrated strong alignment with industry requirements.”

Maintaining Standards

Taking the utility of mobile apps one step

further is the concept of wearable computing devices. Although much of the buzz

and speculation in the technical media has

been focused on which consumer-electronics company will be first to offer a really

practical “smart watch,” other more practical efforts are directed toward development

of wearable devices and systems that can

assist workers in performing—and learning—their job. In the mining industry, this

could lead to relatively simple devices,

such as a ring or bracelet worn by an equipment operator that might allow only the

wearer to operate a specific machine, and

perhaps only within certain parameters

such as time, date, speed or location; or

more complex systems such as virtual- or

augmented-reality simulators that provide

trainees with the ability to participate in

“walk-through” learning sessions, offering

a complete simulated environment in

which the trainee can move freely, perform

tasks, and interact with an instructor as if

he or she were actually in the mine or plant.

Equipment simulator develop Immersive Technologies has taken a step in this direction with the release of its IM360 Advanced Equipment Simulator. The IM360, according to the company, features the flexibility to provide simulation-based training for all machines from Immersive Technologies’ largest range of mining equipment simulator modules including surface, underground hard rock and underground coal equipment. Through the company’s patented RealMove technology, the IM360 allows trainees to freely walk around their mine site and practice responding to emergency evacuations and identify risks in a 360° realistic environment.

Meanwhile, Vandrico Solutions, based in Vancouver, Canada, has been engaged by Motion Metrics International Corp. to integrate their MetricsManager system into heads-up display technology.

Vandrico said its engineers will integrate the MetricsManager software platform into heads-up display technology to create a real-time equipment management system. The system will be manageable directly on the device via voice control. Vandrico will also work with Motion Metrics to ensure continuous support and improvement of the product.

According to Vandrico, which specializes in research and development of applications for wearable devices, the project represents a significant advance for the mining sector and the wearable technologies industry because it introduces new industrial applications for heads-up displays, such as Google Glass. This could revolutionize the way industrial companies manage equipment and safety on a worksite. In addition, savings on operating costs may be possible by constant hands-free control of workplace resources, operations and machinery.

Motion Metrics International said its advanced machine vision and sensor-based solutions use custom-designed hardware and software to address challenging problems in mining. These monitoring products enhance safety, productivity, and connectivity of the customer operations and are currently deployed in more than 50 large surface mines around the globe.

“MetricsManager is the hub of information in the Motion Metrics systems. It is only natural for wearable technology to be one of its channels to engage our many users with useful information,” said Edmond Chow, product manager at Motion Metrics International.