AVEVA’s new E3D Insight offers project management staff the ability to inspect, comment upon, and

approve designs at any time, from any location.

Brazilian Contractor Applies AVEVA Design Solutions on Vanadium Project

“This is a key project for Promon Engenharia and hugely important in the mining sector,” said Fabio Montrezor, Engineering Systems, Promon Engenharia. “During this greenfield project, we are supplying both basic and detailed 3-D engineering designs through the use of AVEVA PDMS. We are then able to share all file formats across the Web in a secure way via AVEVA NET. All people working on the project have access to the appropriate data at each stage of design and construction. Thanks to the adoption of AVEVA’s Integrated Project Execution strategy using AVEVA software, we can organize all elements of procurement, construction, inspection and management, ensuring that all project data is up to date.”

“Many companies that have implemented our design and engineering software together with AVEVA NET have seen the benefits of an integrated approach,” said Santiago Pena, senior vice president–Latin America, AVEVA. “Promon is combining the strengths of our engineering design and information management technologies to enhance data quality and integrity at every stage of this complex project. The adoption of the Integrated Project Execution strategy improves overall project efficiency by shortening schedules, lowering costs and improving the quality of deliverables.”

According to the project’s EPCM, the Maracás vanadium plant encompasses 239,700 m2. It used 10,100 m 3 of concrete, 23,000 m2of formwork, 561,557 metric tons (mt) of mesh sheets, 1,440 mt of metal structures, 235 items of mechanical equipment (2,600 mt), 158 mt of piping, 58 items of electrical equipment, 253 km of power cabling and 1,814 instruments.

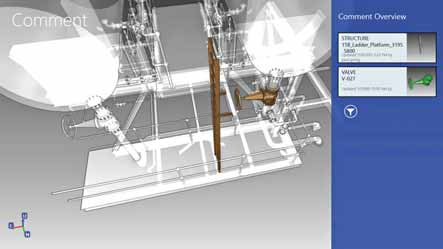

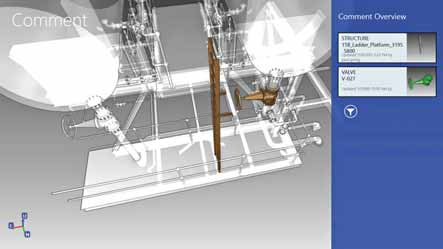

In late October, AVEVA also announced the launch of AVEVA E3D Insight, the Windows 8.1 app that enables project managers to view and approve AVEVA Everything3-D (AVEVA E3D) designs from a mobile tablet device. Developed in collaboration with Microsoft, AVEVA E3D offers the ability to inspect, comment upon, and approve designs at any time, from anywhere around the world.

AVEVA E3D Insight enables users “on

the move” to:

• Visualize—The user can see the AVEVA

E3D model and its associated information quickly and clearly.

• Inspect—The user can inspect, manipulate, and measure the model to check

for such potentially critical issues as

object clashes, accessibility and noncompliance with design standards.

• Comment—The user can liaise directly

with the project’s design team and

leave a permanent record of feedback

in the AVEVA E3D database itself. No

more collating of comments is required

and key decisions are recorded.

• Approve—Authorized users can set

model status to customer defined

approval levels.