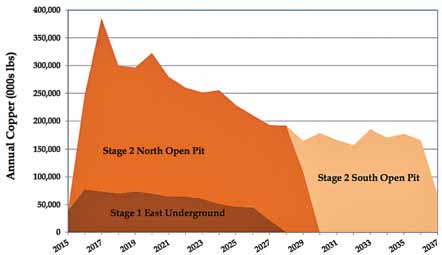

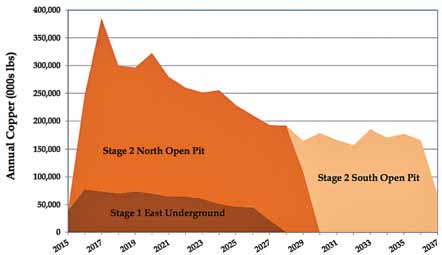

Projected production plans for Nevada Copper’s Pumpkin Hollow underground and open-pit mine stages.

Nevada Copper Eyes 70,000-st/d Open-pit for Pumpkin Hollow

The Pumpkin Hollow open-pit feasibility study confirms the technical and economic viability of a stand-alone, 70,000-st/d Stage 2 open-pit copper mining and processing operation located approximately 4 km west of Stage 1 surface facilities. First production from Stage 2 is targeted for 2016, and mine life is planned at 22 years.

Pumpkin Hollow’s open-pit proven and probable reserves currently stand at 4.1 billion lb of copper in 548 million st of ore grading 0.377% copper. Further drilling is planned and is expected to expand mineral resources and reserves at the project.

Pumpkin Hollow’s average annual open-pit production of copper in concentrates is estimated at 197 million lb/y in years one to 10. Life-of-mine open-pit production of metal contained in concentrates is estimated at 3.7 billion lb of copper, plus 483,476 oz of byproduct gold and 15.0 million oz of byproduct silver.

Initial capital costs for Stage 2 development are estimated at $926 million, including contingencies. Copper production costs net of gold and silver credits are estimated at $1.69/lb for years one to 10.

The Pumpkin Hollow open-pit deposits will be developed sequentially, starting with 1.5 years of pre-stripping the North deposit. Open-pit mill feed will come exclusively from the North deposit until year 12, when ore from the South deposit will be added, probably replacing all North deposit ore by the end of year 14. The current designed pit limit will in time combine the two deposits into a single merged pit.

The initial loading fleet will consist of three 43- to 45-yd 3 electric cable shovels and one 27- to 31-yd 3 shovel excavator. The ore and waste haulage fleet will consist of 13 plus 350-st electric or diesel haul trucks.

A nominal 70,000-st/d concentrator will be located west of the open pits. A large, semi-mobile in-pit crusher will reduce ore size before transport via a conveyor system to the concentrator.

The concentration circuit includes semi-autogenous and ball mill grinding and flotation of copper sulphide, followed by thickening and pressure filtration to produce a final copper concentrate grading 25.5% copper and containing payable gold and silver.

Concentrates will be shipped by rail from to a U.S. west coast port facility.