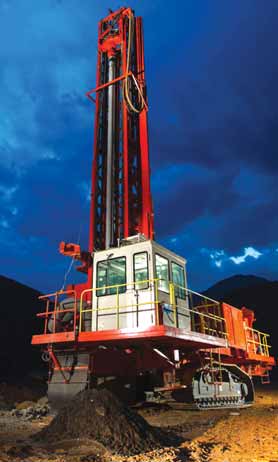

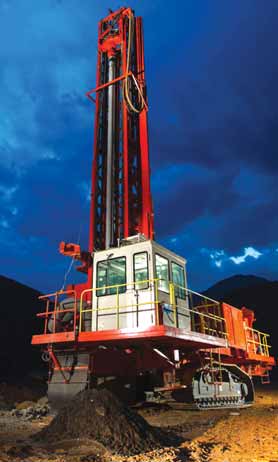

Sandvik Mining’s 1175E electric rotary drill is designed specifically

for customers in the Asian and other emerging market regions.

Sandvik’s New Electric Rotary Rig Sparks Productivity at Chinese Mine

One way these companies are cutting operating and maintenance costs is by purchasing equipment powered by electricity rather than diesel. Recently, the Taihe Mining Industry Company of Chongqing Iron & Steel Group partnered with Sandvik Mining to launch the Swedish equipment manufacturer’s 1175E electric rotary blast hole drill.

Sandvik Mining has been operating in China since 1997, and its operations currently include more than 800 local employees and facilities in Jiading, Wuxi, Luoyang and Tai’an. Sandvik Mining proceeded to develop an electric-powered rotary blast hole drill that would stand up to tough mining environments in that part of the world. The 1175E drill rig was born from this initiative—Sandvik Mining selected Chongqing Iron & Steel Group as its partner in the project. In December 2012, the first 1175E rig was delivered from Sandvik’s Jiading facility to the Taihe iron ore mine near Xichang.

Xiaobin Luo, deputy team leader at the Taihe mine, said, “The domestic rotary drills we use in our mines lack basic features that enable our drills to perform at top efficiency and reliability. In order to optimize our mining operations, we have to explore other options.”

According to Sandvik, electric-powered drills offer several benefits over diesel-powered rigs, including lower operating and maintenance costs. Electric drills have a smaller environmental footprint than their diesel-powered counterparts because they generate less carbon emissions.

The 1175E is an electric-powered, selfpropelled, crawler-mounted rig designed for low-pressure rotary blasthole drilling. It can be safely operated by one person and is equipped for drilling 229–279-mm (9–11-in.) diameter holes to depths up to 53 m (175 ft). Developed as an adaptation of Sandvik Mining’s D75KS rig, the drill was engineered specifically for emerging mining markets and to address safety and efficiency concerns.

The 1175E also was designed with safety and comfort in mind, featuring a two-person operator’s cab that is air-conditioned and heated, equipped with an ergonomic, rotatable seat, and designed to provide the operator with high visibility of the drilling operation. The cab is shockmounted, FOPS-certified and large enough for the operator to stand and use wall console-mounted controls for tramming.

Other major features include an open work deck area fitted with handrails, kick plates and multiple access ladders; an automated cable reel, making this mining process safer and quicker; a PLC-based control system: and a soft start option intended to effectively reduce the starting current, lowering impact on the local power grid and other equipment in operation.

Sandvik reported that, per the contract acceptance clause, the rig achieved 90% machine availability and an average instantaneous penetration rate of 40 m/h in different geological conditions at the Taihe mine site, including hard fractured iron ore.

Luo said, “Sandvik’s 1175E rotary drill exceeded our performance expectations, and is more efficient than the domestic drills we currently have on site. Features such as the advanced control method, efficient pipe handling, automated cable reel, and the powerful undercarriage designed to move easily and quickly are improving our drilling operations.”