Lundin Acquiring Eagle Nickel-Copper Project

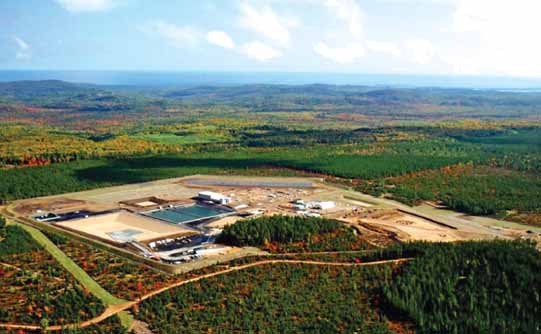

The Eagle mine is located 45 km northwest of Marquette, Michigan, and is served by good infrastructure in a region that has a long history of mining activity. Project construction is slightly more than 50% complete, with initial production expected to begin in the fourth quarter of 2014. Annual production over the first three years of operation is planned at about 23,000 mt/y of nickel and 20,000 mt/y of copper in separate concentrates, plus precious metals and cobalt by-product credits. Life-of-mine production of metal in concentrates over an eight-year mine life is expected to average about 17,000 mt/y each for nickel and copper.

Assets being acquired by Lundin include the Eagle mine; the historic Humboldt mill, which is being refurbished to process Eagle ore; and water, access and surface rights around the mine. Mine development is based on estimated JORC-compliant probable ore reserves of 5.18 million mt grading 2.93% nickel and 2.49% copper. Several exploration targets have been identified in close proximity to the mine deposit.

Total capital expenditures to develop the Eagle project have been estimated at $770 million, of which approximately $355 million had been spent as of the end of May. Lundin estimates that it will spend an additional $400 million to bring the project into production.

The underground Eagle mine is accessed by a ramp, with some 3,000 m of development completed at the end of May. The mine production rate is planned at 2,000 mt/d from long-hole open stopes, with cemented rock backfill. Ore will be transported approximately 105 km by truck from the mine to the Humboldt mill on upgraded existing roads.

The 2,000-mt/d mill processing circuit is based on conventional crushing, grinding, and flotation to produce separate nickel and copper concentrates. The concentrates will be transported by existing rail infrastructure from the mill site to final smelter or port destinations.

Tailings will be deposited sub-aqueously in the adjacent flooded Humboldt open pit. Power is supplied from the grid already connected to the site.

Lundin President and CEO Paul Conibear said, “The Eagle mine represents a very unique opportunity to acquire a high-grade project that is under construction and expected to begin generating significant levels of metal production and cash flow prior to the end of next year. Northern Michigan has an outstanding iron ore, gold and base metals mining history, and consequently excellent regional power, road and rail infrastructure, with extensive mining expertise within local communities to support and staff the Eagle mine.”

Lundin Mining is headquartered in Tor ont o, Canada, and has wholly- owned base-metal mining operations in Portugal, Sweden and Spain. The company also holds a 24% equity stake in the Tenke Fungur ume copper- cobalt mine in the Democratic Republic of Congo and in the Kokkola cobalt refinery in Finland.