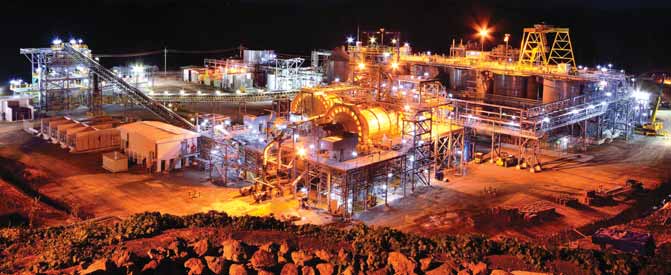

An aerial view of the Martabe site with the Purnama Ridge mining site at left and the processing facilities in the center.

G-Resources’ Martabe Mine and Mill Ramps Up to Full Capacity

Indonesia’s newest mining operation achieves significant milestones

By John Miller, Editor, The ASIA Miner

The project has generally met expecta-tions since first gold, has exceeded the guid-ance put to the market in October for the remainder of 2012, and is still doing very well, explained Peter Albert, CEO, G Resources. “After first gold on July 24 there was still some construction to be done which was completed by the end of September with the last construction workers leaving the site by mid-October,” Albert said. “August was a commissioning month, we started to ramp up in September, had a hia-tus from mid-September to the end of October with a shutdown, and then in November and December we came back into it at full steam with December being a crack-er month, and it has continued since then.

“We plan to reach design capacity in the second quarter and are on schedule for that, more than likely in the early part of it,” Albert said. “Although we are still ramping up the processing plant, we are very pleased with its performance. As with all plants there are a few niggles to be remedied and tweaks to be made but we did a lot of that during commissioning and by December were at about 80% capacity in the milling circuits and more than 100% in gold production due to the fact that the grade was very good and recovery was fantastic. We are progressing very well on the ramp-up curve and at times have hit nameplate capacity and even exceeded it.

“We are mining down the ridge at Purnama and by early February had come down 40 m,” Albert said. “Contractor Leighton Indonesia is doing a fabulous job. There are a number of areas opened up on the ridge where we are extracting ore and a number of stockpiles developed from which we are shifting material into the ROM and crusher feed. As far as grade control is con-cerned, we continue to deliver against the resource plan and often a little bit better.”

G-Resources is working with two con-tractors at Martabe, who, Albert believes are excellent big fleet contractors, all with the right equipment. “Leighton Indonesia is car-rying out mining at Purnama and most work on the tailings storage facility—lifting the dam wall with waste and other material from the mining process,” Albert said. “There is also Indonesia contractor, Nusa Konstruksi (NKE), which has been with us for six years through development, construction and into operation. NKE’s work is lower down in the valley and their basalt quarry generates some nice rock for our tailings facility, for construction as well as general site works. As the mine opens up we may move away from articulated dump trucks to rigid body vehicles but at the moment we have the right equipment for the job.”

Albert explained that there are different areas at Purnama from where consistent feed is delivered to the plant with the grade, tonnage and material type coming together nicely. “Process plant throughput is going extremely well and the most pleasing aspect is that we are achieving recoveries of better than 90%,” Albert said. “We are also ahead of the game with the tailings storage facility and construction is going very well. Executive General Manager Tim Duffy has played a major role in helping us get this far. He has been at Martabe four years, building the operation, shepherding it through con-struction, and now ramping up operations.”

A New Mine Opens

in Indonesia

The Martabe mine is the first major mining

project to be developed in Indonesia in the

last 10 to 15 years. It sits on the western

side of Sumatra in Batangtoru sub-district of

North Sumatra province. The mine is estab-lished under a sixth generation Contract of

Work (CoW) signed in April 1997 and which

defines all terms, conditions and obligations

of G-Resources and the government of

Indonesia for the life of the CoW.

The Martabe resource base consists of seven known deposits within a 30 km 2 area with Purnama the largest so far. Martabe commenced first commercial gold production from the Purnama pit in July 2012. The Martabe mine benefits from a low estimated life-of-mine cost structure for the Purnama pit, which is a result of the capacity and size of the project, the shal-low nature of the deposit that results in a low strip ratio of 1.3:1, the good grade of the ore and straightforward gold extraction process. The project is also in a great loca-tion, close to highways, airports, port, power and a significant national skilled human resources pool.

The Martabe operation encompasses the Purnama open-pit mine, a convention-al processing plant with 4.5 million mt/y capacity, a permanent accommodation facility for mine workers, haulage roads, high voltage switchyard, onsite workshop and warehousing, and a tailings storage facility with associated water catchment and diversion systems. The Martabe plant consists of single stage crushing, semi-autogenous grinding and ball milling (with the SAG mill close-circuited with a pebble crusher), and a carbon-in-leach circuit.

The cash cost per ounce equation is a work in progress, Albert explained. “We have assessed the consumption of consum-ables and costs of reagents, labor, etc., and have established a figure of about $450/oz as our guidance for 2013,” Albert said. “Most gold industry players are experienc-ing significant cost pressures so we are pleased to be where we are with cash costs and there are opportunities to improve. We are operating on diesel power but when we get on to the main grid there will be a sig-nificant shift downward in terms of our cost structure and we are pushing hard to make this happen as quickly as possible.” The electrical infrastructure from the mine to the grid is in place and they are working with the Indonesian power supplier, PLN, to compete the tieins.

Environmental Concerns

and the Community

Operations were shutdown in mid-September owing to an objection being

lodged with respect to the discharge of

clean water to a river. “The system was

approved as part of our environmental

approvals but after we were up and running

we had some objections from a relatively

small part of the 30,000-strong communi-ty living around the operation,” Albert said.

“We are not about to get into conflict with

anybody and much prefer to sit down, talk

and work through the issues.”

Martabe has 4 m of annual rainfall and there is a positive water balance with most being rainwater coming off the hills. “The water is contaminated when it enters the tailings storage facility but we use most of it in the processing plant,” Albert said. “If there is excess water, we have a highly tech-nical water polishing plant that cleans it to strict environmental requirements and then releases it into the river with no impact on aquaculture or agriculture. Despite the sci-ence, we have to deal with community per-ception so, with government help, we met with the concerned people over a period of time and worked through the issues.

“By the end of October we had reached agreement with the community and could resume construction of the clean water pipeline,” Albert said. “This work was com-pleted within two weeks and it was put into operation with the process plant re-started at the same time the pipeline work resumed. The shutdown had some impact because we weren’t operating but we took the opportunity to remedy a number of mechanical issues in the front-end of the plant. Therefore, at the restart we were able to come at it very fast which minimized production lost during the six weeks.

“We communicated extensively with local communities before beginning opera-tions, as we always have, but something went wrong somewhere and we acted accordingly and responsibly,” Albert said.

“We obviously didn’t get it right and have learned from the experience as we rebuild the bridges and re-nurture the relationship. We have to ensure we keep working at the relationship and never rest on our laurels as it is a space in the min-ing industry that is not black and white. It’s not like engineering that you can fix with dollars, calculations and time, it is about perceptions and is, therefore, an opaque and challenging area. In this instance the team did very well when the issue arose. We believe the event has demonstrated to the government and the community our credentials in terms of our commitment to consultation, communica-tion, engagement and building a long-term sustainable future.”

Committed to CSR

G-Resources has an extensive corporate

social responsibility (CSR) program.

“During exploration you tend to be a little

tentative with CSR because you have no

commitment to build and you don’t want to

build expectations,” Albert said.

“When moving into feasibility and con-struction, you have something long term and the commitment becomes greater. Then you move into operations with result-ing cashflow, giving you the wherewithal to make substantial improvements to the long-term welfare and sustainability of that environment. We are already seeing that around Martabe with banks arriving, mechanical workshops being established and supermarkets opening—wealth that is being generated by mining. Seeing people who are relatively impoverished become relatively prosperous with better education, better health and more opportunities for their children, all over a short period of time, is one of the most satisfying things you can achieve in your career and I’ve been fortunate to see it a couple of times.”

Approximately 70% of Martabe’s work-force is local, amounting to 1,400 to 1,500 people, and this is a huge positive impact on communities and families. “We have also provided 5% mine ownership to the local government resulting in direct dividend flow from the profits with a per-centage of that dedicated to CSR,” Albert said. “We have medical programs includ-ing malaria prevention, malnutrition edu-cation and prevention, mother and child health care, and AIDS education, while we also do a tremendous amount in the edu-cation field—reading gardens, supporting schools, developing school infrastructure, sponsorships, etc. We are involved in busi-ness development with micro-finance, agri-cultural programs, rice improvement tech-niques, fish farms and those sort of things.

“Even though everyone would love a job we can’t give everyone a job, so we endeav-or to ensure everyone benefits from devel-opment of such an enterprise and everyone sees lifestyle improvements,” Albert said. “We are focused on ensuring we touch every family in some form so that everyone participates and gains a benefit. The long-term vision is to build a sustainable future for people beyond the mine life.”

Exploration is a Priority

Exploration is a priority and there are a few

legs to the program. There is a budget of

around $17 million for 2013 and chief

geologist Shawn Crispin is running the pro-gram. It is a large CoW and within that is

the Martabe area, which at this stage com-prises seven deposits. This year the com-pany is focusing on:

• Replacing depleted ore reserves from mining thus retaining current reserves and mine life;

• Generating more resources from existing targets and new targets to provide longer mine life and potential to expand the operation; and

• Focusing on a specific drilling program to identify a sulfide resource. Most of the deposits have significant sulfide miner-alization at depth below the current pit outlines. G-Resources had drilled a num-ber of metallurgical sulfide holes to gen-erate samples, which have been taken, prepared and will be delivered to labora-tories for a metallurgical sulfide test work program.

“On the larger CoW area we have a num-ber of exciting targets and are working on the Southern Corridor, Tango Papa and Pahae, and we will probably go back into Golf Mike this year as well,” Albert said. “We are look-ing for similar systems to Martabe and have identified a number of good opportunities, had some good results, and are continuing with specific drilling programs at the Southern Corridor and very soon at Tango Papa. In other areas we are more on the ground with geochemical and geophysical survey work. Across the CoW we continue to look for a buried copper-gold porphyry. We believe this is very good hunting ground for such a system—there is lots of smoke and we have done a fair bit of work with a num-ber of holes giving us encouragement.”

Operationally, this year the company will focus on a number of key areas. “First, get-ting the ramp-up behind us and reaching nameplate capacity, which is not far off and then the pressure will be on to determine what can be obtained from the process plant through debottlenecking and opti-mization, and there are some very positive signals,” Albert said. “We have had some short runs at throughputs well above design capacity and we’ll be looking to maximize that through the remainder of 2013. From an engineering perspective we are also look-ing to tweak the process to get the maxi-mum from it with little capital expenditure, if any. This should enable us to get maxi-mum value out of this operation.”

What the Future Holds

“For now the company is focused on the

Martabe area and we think the sulfide pro-gram is at least a significant shift but also

a potential game changer as it may add sig-nificant ounces to the production profile,”

Albert said. “Some of the sulfides are at

surface, such as at Horas; at Purnama they

exist within the current pit outline and just

below it; and there may be others at deep-er levels that may require underground

development but that is very futuristic from

where we sit now.

“Once we get into significant cash flow and get the share price up, we can rethink our approach as far as what happens beyond Martabe, whether in other parts of Indonesia or further afield. We have the wherewithal to do that—the right people, right skill set and in time we’ll have the right financial profile.

“We are the first major mining project to be developed in Indonesia for 10 or 15 years and we have been attracting strong interest at regency, provincial and national government levels as well as in mining circles around the world. We have shown what can be done in Indonesia, which from an international perspective has been seen as an ever-changing investment destination where the rules have not been clear, making it difficult to make any big investment leaps. When people see what we have achieved, it generates greater confidence and an understanding that these things are achievable as well as showing that it is a workable environment.

“Indonesia is no more difficult or chal-lenging than anywhere else, and probably a lot easier than many other resource-rich environments,” he says. Government has been tremendous throughout the entire process and has been very supportive at all levels in terms of helping us over the various hurdles. What we have been able to achieve is the ability to get things done in this sort of environment by networking, developing relationships and having the right, key Indonesian people on our board and at man-agement level. It’s the senior Indonesian people who make it all happen and they have done that very well at Martabe, led by Deputy President Director Linda Siahaan.

“We are here in the country and when we look at potential opportunities for devel-opment of mining projects, we have three criteria: is it an environment where you would be prepared to work yourself—is it safe for the people you are going to send there; is it minerally prospective; and is it a workable place, an environment in which you can get things done and work through the system. Indonesia ticks all three boxes—there are no safety issues of any great consequence and it is a very safe environment in which to bring families; Indonesia is part of the Pacific Rim of Fire and with the Philippines and Papua New Guinea, is probably one of the most prospective places on the planet, and very largely underexplored; and we have just demonstrated that you can get things done in Indonesia. If you have the right people, the right resources, the right commitment and dedication, then it is very workable.”

The G-Resources’ CEO says that for the mining industry in Indonesia it is a case of “watch, wait and see” as there is still a lot of uncertainty. “Martabe is attracting a lot of interest and people will say that it can be done but because we are in country, we understand how to work here. Others looking to enter this environment would have greater difficulty coming to terms with it, and understandably so. We see that as an oppor-tunity for us whereas others may not wish to enter as they see the level of uncertainty as a result of the changing regulations,” Albert said. “The mineral potential here is such that it can only be developed in the future and the long-term future for the mining industry has to be very positive.”