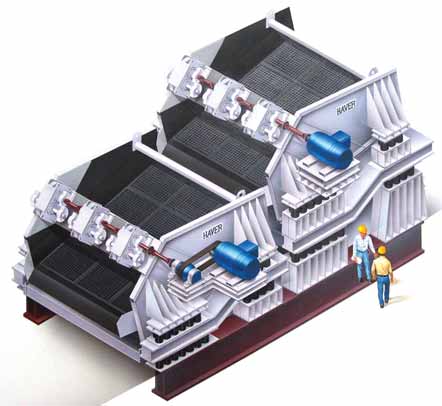

W.S. Tyler says its XL-Class vibrating

screen combines advanced drive technolo-gy with a wide body to offer better screen-ing action and more throughput. Larger

than any other vibrating screen from W.S.

Tyler, the XL-Class is intended for high ton-nage production rates, and features exciter

drive technology that ensures smooth oper-ation and high uptime. The linear stroke is

generated by counterweights mounted on

two machined shafts that spin in opposite

directions via two heavy-duty spur gears

attached to an iron casting that mounts to

the exciter bridge. The bridge is the main

exciter support and transmits dynamic

force through the entire structure. In addi-tion to better operation, the exciter design

increases bearing life up to 50,000 hours,

according to the company.

The XL-Class offers screening surfaces

of up to 390-ft

2(36 m^2

), facilitating pro-duction rates up to 15,000 tons per hour

and cut sizes from 1/4- to 5-in. (6–127

mm) with varying degrees of incline. The

XL-Class can be configured as a banana

screen—an approach that can be espe-cially effective when the feed contains a

large quantity of fines that are much

smaller than the opening of the screen

media. To provide added strength, the XL-Class features a Huck-bolted screen body

fastening. Side plates are constructed with

high-strength carbon steel. The area sur-rounding the shaft assembly is strength-ened with a reinforcing plate that ties

together the side plate, screen panel and

shaft assembly.

www.wstyler.com

As featured in Womp 2012 Vol 08 - www.womp-int.com