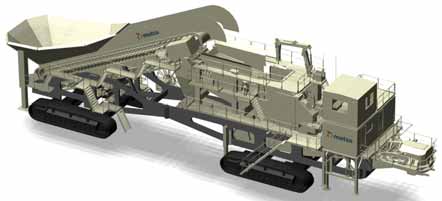

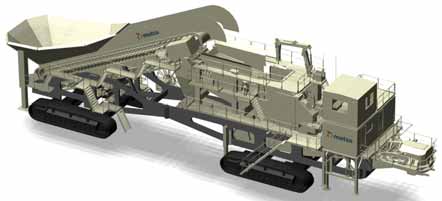

As part of a $13.4-million equipment delivery to a mine in Kazakhstan, Metso will provide a track-mounted LT200

jaw crusher—a model of which is shown here—along with a large mobile feeding and conveying system.

World’s Largest: Metso Jaw Plant, FLS Ore Drying SystemA

A Metso Lokotrack LT200, weighing almost 400 tons and able to process ore at a rate of 2,500 metric tons per hour (mt/h), is the heart of the installation. The entire mobile system weighs more than 800 mt, but is easily movable when relo-cation is necessary, according to Metso.

When set up, fragmented copper ore will be fed by a Metso MAF210 mobile apron feeder to the Lokotrack LT200 jaw plant, and then transported by a Nordberg LL16 mobile conveying system and track-mount-ed stacker to the mine’s main conveyor net-work. The loading height of the tracked mobile apron feeder is 6 m, with feed hop-per volume of 24 m3 . The C200 jaw crush-er, the largest made by Metso, can handle ore feed lumps up to 1.2 m in size.

The wheel-mounted LL16 mobile con-veyor has two conveyor elements, each 42 m long. The track-mounted stacker has a discharge height ranging from 3-10 m. The entire mobile system is electrically powered.

Altay Polimetall, based in Almaty, Kazakhstan, will extract copper ore from the new mine at a projected rate of 3 mil-lion mt/y, plus gold.

In news at the opposite end of the pro-cessing spectrum, FLSmidth said it has received an order worth approximately $90 million from the Moroccan company, OCP Office Chérifien des Phosphates, to supply equipment and technology for a phosphate terminal in Jorf Lasfar, 120 km south of Casablanca.

The order includes delivery of a com-plete flash drying system for drying de-watered phosphate ore. With a capacity of 31,000 mt/d, it reportedly will be the largest phosphate flash drying system in the world. The scope of supply also includes combustion and pelletizing systems and air pollution controls in-cluding a limestone-based flue gas de-sulphurization system.