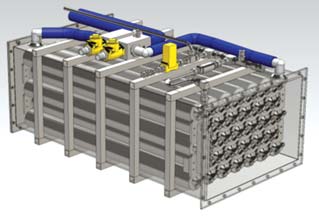

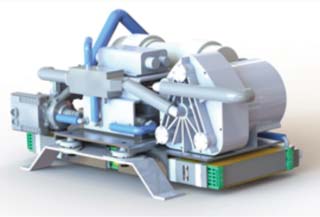

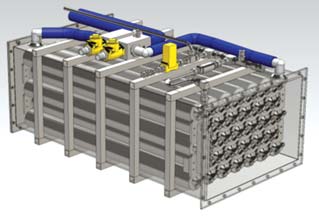

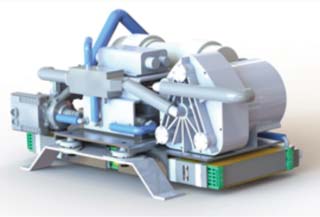

CAD models (not to same scale) of VP’s reversible metal-hydride storage

system (top) and fuelcell powerplant.

Fuelcell-powered Locos Bound for Underground Platinum Duty

The purpose of these innovative vehicles, according to the two parties involved, is to assist in mining platinum in a more eco-nomical, energy-secure and environmentally benign manner. The locomotives will not require any electricity from the grid to func-tion, and will not emit any noxious gases. VP, as prime contractor, is executing engineering design, fabrication and testing of the fuelcell powerplant and reversible metal hydride storage system in its facility in Golden.

VP’s hybrid fuelcell powerplant employs Ballard proton-exchange membrane FCvelo-city-9SSL V4 stacks and K2 Energy lithium-ion batteries. Continuous fuelcell net power is 17 kW, and together with the traction bat-tery, maximum net power is 45 kW for approximately 10 minutes. The powerplant will fit within a 0.1-m^3 box, and the volume of the powerplant plus battery is 0.5 m^3 . Low-temperature waste heat from the power-plant is the source of energy to store, release and distribute hydrogen in the vehicle.

VP said its reversible metal-hydride stor-age unit provides hydrogen-dense, energy-efficient, ultra-safe storage of hydrogen for underground operations. It is designed to store 3.5 kg of hydrogen (50 kWh electrical output at the fuelcell) and to be refueled underground from 20 bar hydrogen in 10-20 minutes. During refueling, either waste mine water or ambient mine air will cool the hydride bed. Operating hydrogen pressure is only 10 bar gauge. The storage unit will fit within a 0.3-m^3 box.

The entire power-dense locomotive power module—fuelcells, batteries, hydride storage, cooling system and power electron-ics—requires only 1 m^3 of volume. Upon completion of testing of the power module (expected in March–April 2012), the unit will be shipped to VP’s locomotive project partner, Trident South Africa, in Johannesburg for integration into a Trident 10-ton New Era locomotive. Integration, locomotive testing and demonstration, ini-tially at the Trident surface test track, will be assisted by VP’s project partner Battery Electric of Johannesburg.

Amplats is funding the project and will serve as the end user of the developed fuel cell mine locomotives. Amplats is a mem-ber of the Anglo American PLC Group and is the world’s leading primary producer of platinum group metals. Its platinum min-ing, smelting and refining operations are based in South Africa.

Vehicle Projects Inc. develops turnkey prototype fuelcell vehicles. It developed and demonstrated the world’s largest hydrogen-fuelcell land vehicle, a 130-mt railway locomotive.