Like so many other materials used in min-ing applications, the geosynthetic products

used for lining heap leach pads, tailings

storage empoundments and settling ponds

often have to survive physical or chemical

damage from all sides. Just as a plant

process vessel can come under attack from

abrasive contents on the inside as well as

corrosive mist or fumes on the outside, ‘geo’

materials frequently must cope with sharp

rock edges in the overlying material or under

the liner, physical slippage due to slopes or

ground movement—and age, to mention

just a few threats. Liners are often expected

to stand up not just to the rigors of mining,

but possibly to many years of post-mining

exposure as well. In many cases, a mine

might only be active for 10 or 20 years, but

its covered and lined pads and dumps may

have life spans measured in centuries.

The selection of a proper liner or cover

is complicated by the fact that each mine

site is, in some way, unique. There are few

cookie-cutter solutions available to the

industry for almost any phase of mining

and processing, and liner selection must

take into account variables that range from

local terrain characteristics, to the chemi-cal makeup of contained leach or waste

solutions, to the level of oxidation resulting

from exposure to sunlight or heat. The good

news is that there is a wide and growing

selection of geomembrane, geosynthetic,

geocomposite, nonwoven geotextile and

related products available from which to

choose, and suppliers continue to advance

materials technology and installation choic-es to provide higher levels of performance.

For example, long-term tests conducted on

HDPE (high-density polyethylene) geo-membranes, the most widely used liner

material, exposed to various climatic condi-tions indicated that the material’s anti-oxidative ingredients were still active after

three decades. New linear low-density poly-ethylene (LLDPE) geomembranes also offer

better protection against stretching caused

by weight loads or ground movement.

That’s welcome information to mine

operators concerned about the loss of poten-tial revenue from seepage of metals-rich

solutions through punctured liners, particu-larly during metal-price boom times. Studies

of seepage in heap leach pads estimate that

leakage levels for these types of applications

can reach as high as 10,000 liters/hectare/

day. Add to that the growing emphasis on

runoff control and acid mine drainage, plus

increased regulatory and public attention to

mine-closure plans and responsibilities, and

the expanding importance of liner integrity

comes into clearer focus.

Improving Liner Performance

E&MJ recently spoke with executives and

engineers at GSE Lining Technology, which

has supplied liner products since the early

1970s—about the same time that geosyn-thetic liners caught the attention of the

mining industry. GSE manufactures geo-membranes, geosynthetic clay liners and

drainage products to serve the global min-ing market. According to Ed Zimmel,

GSE’s vice president of engineering, the

mining industry has high stakes riding on

geomembrane performance.

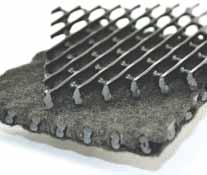

The rising importance of liner leak minimization has prompted geomembrane suppliers such as GSE Lining Technology to develop new products and techniques.

The rising importance of liner leak minimization has prompted geomembrane suppliers such as GSE Lining Technology to develop new products and techniques.

Shown here, left to right, are GSE’s new leak-location lining membrane (being tested); an illustration showing how the leak location liner and new mine drainage

net product are placed for a typical heap leach pad installation; and a closeup of the geocomposite drainage system itself.

Zimmel noted that the suppliers of resins

used to manufacture geomembranes have

continued to make significant improve-ments in their product—advancing catalyst

technology and refining their process condi-tions, for example—that, in turn, allow geo-membrane suppliers to offer better-perform-ing products. In addition, the chemical

additives that are included in geomembrane

production recipes have improved, adding

increased thermal stability and resistance to

damage from UV radiation.

Mark Harris, GSE’s global mining market

manager, added that although these im-provements seem somewhat basic, they’re

of high importance to mine owners that have

to plan for decades of post-mining care and

maintenance and final closure of facilities.

Liner longevity and integrity are key ele-ments in avoiding environmental incidents

both during and after mining activities.

“We pursue product development very

aggressively,” said Zimmel. “We try to get

out in front of the engineers and mine own-ers by first asking them what they need in

terms of product performance, and then

developing liner products that meet those

demands. We want to identify any product characteristics that may cause engineers to

have to modify their site designs, and elim-inate those constraints.”

GSE recently introduced a line of High

Performance LLDPE and HDPE geomem-branes that are designed to provide notice-ably better resistance to most of the chal-lenges faced by mine geomembrane instal-lations: i.e, higher resistance to stress

cracking, increased anti-oxidation protec-tion that can result in longer field life, and

enhanced capability to cope with differen-tial settlement stresses that can sometimes

cause liners to stretch multi-axially by as

much as 20%. This is a particularly useful

characteristic for leach facilities located in

seismically active areas.

The new geomembrane line, according

to the company, is manufactured with two

anti-oxidant chemical packages rather than

a single all-purpose package common in

most geomembrane ingredient lists; one

package is aimed at preventing oxidation

during the manufacturing process, the

other at protection in the field. Another

additive package protects against brittle-ness caused by aging.

In addition to the new High Performance

geomembrane, GSE is introducing a syn-thetic drainage system that replaces the

aggregate commonly used as a drainage

layer on a typical leach pad. This system can

result in better performance and lower costs

for the project owner by eliminating the need

to find, crush, or truck-in aggregates, as is

the case at many pad facilities. The synthet-ic drainage system provides enhanced punc-ture protection for the liner system. Another

new product in the GSE pipeline is a leak-location liner that can be tested for pinholes

not only after installation, but after place-ment of the drainage system as well, conse-quently offering the prospect of preventing

significant solution and mineral loss.

A Textured Approach

Liner installations can employ either

smooth or textured geomembranes, de-pending on whether the site requires a

higher frictional interface between the liner

and the underlying surface or not. Agru

America Western Regional Manager Clark

West described one of the popular process-es used to produce textured geomem-branes in a presentation given at the 2011

annual meeting of SME. An embossed or

structured texturing is created by extruding

molten polyethylene between two precisely

engineered rollers. A pattern on one or both

rollers creates a corresponding pattern of

spikes on the extruded sheet, he explained.

There are several benefits offered by this

approach, West noted: the base thickness

of the material is not affected by the

process, and the sheet surface remains

smooth with the exception of the spikes.

Tensile and strain properties are not

degraded in the manufacturing, and the

material is completely homogeneous.

Agru America supplies these textured

geomembranes in several configurations,

including Microspike, which offers a high

frictional interface; and Grip Liner, with

smaller spikes for lower friction. The com-pany’s Super Gripnet contains drain studs

on the upper surface and spikes on the bot-tom surface—a useful configuration when

the sheeting is applied on slopes, while its

Micro Drain liner has studs on the top sur-face only, for use when applied over fabric

or geosynthetic clay.

Because of past liner failures and expe-riences with poor post-mining performance,

new options are being sought by engineering

customers tasked with designing stable and

environmentally sound solutions for waste

rock dumps and leach pads, West ex-plained, and an exposed geosynthetic cover

system developed by Agru America may pro-vide an answer. The system incorporates a textured geomembrane in combination with

synthetic turf and a highly transmissive

drainage layer above the membrane. The

drainage component, locking infill ballast

and internal friction angles allow for instal-lation of the cover on steep slopes that nor-mally would require significant angle reduc-tion. The system is claimed to provide rapid

installation and superior environmental

characteristics, resisting damage from hurri-cane force winds and intense rain events.

Other advantages, according to West, are

that it eliminates the need for borrow,

reduces earthwork costs, fuel consumption

and ongoing maintenance required by a veg-etative closure, (e.g., re-seeding, soil

replacement, fertilizing and irrigation).

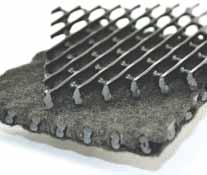

A typical geosynthetic clay liner, as shown here,

A typical geosynthetic clay liner, as shown here,

com-prises a layer of sodium bentonite granules or

powder sandwiched between woven/nonwoven

fabric sheets.

Composites to Control Leakage

Even the most well-designed geomembrane

mine installation is likely to have some leaks

due to imperfect seams or damage incurred

during installation and loading phases,

explained CETCO’s Chris Athanassopoulos in

another presentation at the 2011 SME

meeting. To control leakage through defects,

a low-permeability layer can be used beneath

the geomembrane to form a “composite”

liner system. The low-permeability liner

beneath a geomembrane is typically either

compacted soil (clay or silt) or a geosynthet-ic clay liner (GCL). GCLs are factory-manu-factured products that employ sodium ben-tonite and have a laboratory-certified

hydraulic conductivity of 5 x 10^-9

cm/sec.

Although many factors can affect the

rate of leakage through composite systems,

including the number of holes in the overly-ing geomembrane, the hydraulic conductiv-ity of the underlying soil layer and the qual-ity of contact between the geomembrane

and the low-permeability layer, liner-leakage

measurements collected by the U.S. EPA at

almost 300 landfill cells, spanning 91 sites

showed that GCL-based composite liner sys-tems allow less leakage than clay-based

composite liner systems, he noted.

CETCO’s Bentomat GCL products offer

the company’s Supergroove technology,

consisting of a groove in the nonwoven fab-ric that allows the contained bentonite to

migrate out and self-seam at the overlap.

This feature, according to CETCO, eases the

installation process by eliminating the need

for supplemental bentonite.

Athanassopoulos said comparisons

between installed costs of GCLs and com-pacted soil liners are problematic due to the

highly variable, site-specific issues posed

by each installation. However, his experi-ence, including a recent mine project in

Nevada, has shown the installed cost of a

GCL is roughly equivalent to or lower than

the installed cost of a compacted soil liner

when the soil is transported from an off-site

location, or when soil amendments such as

bentonite are required. GCLs often can be

deployed faster than compacted low-per-meability soil liners can be constructed,

and offer a better working surface for

deploying and welding the overlying

geomembrane. Additionally, GCLs are fac-tory-controlled materials, with consistent

bentonite distribution and hydraulic per-formance. These advantages, said Athanas-sopoulos, suggest that GCLs may facilitate

a shorter construction schedule and an ear-lier start to leaching operations.