It wouldn’t be totally surprising for someone

hearing the gist of a story involving two

Scotsmen, a new twist on centuries-old

technology, an abandoned industrial property

in a Southern African monarchy and

the ongoing quest for deeply buried gold to

imagine they were perhaps listening to the

outline of a movie script—or maybe just

the beginning of an intriguing bar tale.

Quite the contrary, these are the principal

components of Peterstow Aquapower, a

hydropower-focused enterprise that is

knocking on the doors of conservative

South African precious-metal mining houses,

promising significant operational and

financial benefits for an industry facing

stiff challenges in both areas.

Peterstow’s business is water power, a

technology that has been used for centuries

and which has been applied in many

forms by the mining industry—including

everything from high-volume water cannons

used by placer miners to sluice down

gold-bearing gravel from hillsides in

Alaska, to experimental high-pressure

water jets designed to micro-fracture hard

rock formations underground. There are

already water-powered rock drills in service,

both in South Africa and elsewhere.

For Peterstow, however, the technological

focus is on precise control and recycling of

relatively small volumes of water to efficiently

power an innovative drill body that

uses conventional drill steel and bits.

Peterstow Aquapower is the manufacturing

arm of Peterstow Holdings, a private

company formed in the U.K. by the father

and son duo of Douglas and Alan Barrows

to develop marketable technology employing

closed-loop water hydraulics, particularly

as it might apply to drill-and-blast

mining methods used by South African

gold and platinum-group metal producers.

Douglas Barrows, 66, is the chairman of

Peterstow and Alan, 39, is executive director,

responsible for day to day operations,

including product development and manufacturing.

He oversees the Peterstow manufacturing

facility at Ngwenya in

Swaziland, a small country sandwiched

between South Africa and Mozambique.

Peterstow has offices in Johannesburg and

Durban, as well as in the U.K., and also

owns Dudley Associates, a company specializing

in plastic molding tooling and

materials.

During a recent tour of its African operations,

Douglas Barrows was quick to

explain Peterstow’s business philosophy to

E&MJ. “We are not miners. We are specialists

in water hydraulics technology,” he

said—but then added he believes the company’s

drill design “is the single most

important piece of technology to hit the

mining industry in 50 years.”

Barrows said he began pursuing possible

applications of the technology in the mid-

1980s and was later encouraged by

Raymond Tarr, former chief of Anglogold’s

technical services group, to look into the

possibility of developing a water-powered

drill that could potentially replace the thousands

of compressed air-powered drills used

throughout the South African mining industry

and elsewhere. Although air-powered

drills were the best available technology at

the time, they are noisy, emit an obnoxious

oil mist, and in extremely deep operations

such as those found in the South African

industry, require extensive and expensive

infrastructure to deliver compressed air to

the lowest levels of the mines.

“Compressed air is an inefficient use of

energy,” said Barrows. In the deep underground

mines of South Africa, a compressed-

air drill is just the distant end of

what can be thought of as a huge machine

with most of the apparatus—electric

motors, compressors and other ancillary

equipment—on the surface, many kilometers

away. According to Peterstow’s estimates,

for every 100 kW put into a compressor

on the surface, as little as 1 kW arrives at the intended source; the rest is

lost along the way. A single large deep-level

mine can incur electricity bills of well over

$1 million per month in the South African

power system, even with relatively cheap

rates of around $0.06/kW-hr.

Ian Cockerill, former CEO of Gold Fields

and currently chairman of South African

coal and silica producer Petmin, has been

an adviser to Peterstow for roughly a

decade. He also believes the water-powered

drill technology can be a game-changer for

the South African mining industry. “This is

a breakthrough technology which can give

a huge leap in productivity. This kind of

innovation means the mines can still operate

while reducing their power requirements,

and at the same time get a much

more efficient drill which gives you more

operating time at the face,” he said.

What’s Involved

The Peterstow Aquapower drill consists of

two units—the drill itself and a power pack

about the size of a compact refrigerator.

The two assemblies are connected by

hoses and operate in a closed-loop system

that uses a minimal volume of water—continuously

recycling that water from the drill

to the power pack—and emits nothing to

the surrounding atmosphere. The only

external inputs needed are an electrical

supply for the power pack and a low-volume

source of mine water to flush the drill

cuttings from the blast hole.

At about 28 kg (62 lb) the drill itself is

relatively lightweight and has a minimal

number of moving parts. The power pack

weighs 275 kg (600 lb) and measures 790

mm high x 650 mm wide x 850 mm deep

(32 x 26 x 34 in.). It produces 110 bar

(1,600 psi) of hydraulic pressure for drill

operation. The drill itself requires a water

flow rate of 36 liters/min (9.5 gpm) and

has a maximum strike rate of 1,950 blows

per minute. The power pack, which incorporates

a rotary hydraulic motor developed

by Danish fluids-handling specialist

Danfoss, and drill are connected by two

hoses that allow the two units to be separated

by considerable distance—thus

allowing the power pack to be located outside

an active stope, for example. The

accompanying sidebar shows the principal

components and sequence of operation.

The power pack is available in two

power ratings: 7.5 kW and 15 kW. The

more powerful version is intended specifically

for rig mounting.

Although the level of technical design

and innovation incorporated into the drill is

an interesting topic in itself, Peterstow’s

management and advisers are enthusiastic

about the bigger picture—the ‘gamechanging’

potential of water-hydraulic drill

technology to provide economic relief to an

industry plagued by high operational costs

and prospects of those costs getting much

higher in the not-too-distant future. For

example, a South African precious-metal

mine’s typical energy costs three or four

years ago were in the range of 8% to 10%

of unit costs; in the future, that is expected

to rise to 15%.

A typical large South African underground

mine can have thousands of compressed-

air drills in service throughout the

property and it’s estimated that, across the

entire industry, several hundred thousand

blast holes are drilled each day. The infrastructure

required to support the compressed

air, ventilation and cooling, and

water requirements of these operations is

massive and expensive to install and maintain.

In addition, power shortages have significantly

impacted the South African mining

industry and will continue to do so;

Eskom, the state-owned power utility, currently

requires mines to use 10% less power

than they did a year ago, and it is likely to

demand additional cuts in the near future.

These cutbacks could reduce mine production

by as much as 40%, according to

Peterstow’s estimates—but Douglas Barrows

believes widespread integration of his company’s

technology could help boost the

industry’s production to the levels achieved

before the power cuts were imposed.

As an example, he said 500 Aquapower

drills would use 22,500 kW-hr of energy in

a month, based on a six-hour daily drilling

period, compared with an equivalent number

of air-powered drills that could require

as much as 3 million kW-hr. The capital

costs for the Aquapower drills, he said,

would be about $18.5 million per 1,000

units, compared with $40 million for an

equivalent number of air-powered drills and

the infrastructure needed to support them.

Because the water consumption of the

Aquapower drills is lower—less than two

tons of water per ton of ore extracted, compared

with five to six tons of water per ton

of ore with pneumatic technology—the volume of water required by the industry could

be reduced by 20 million tons per year.

Overall, Peterstow claims its drilling

system is capable of operating on less than

1% of the energy required by some conventional

drilling systems, and 40% to

60% less water consumption.

“It appears there is a real financial case

to change from…conventional drills to

Peterstow’s remote closed-loop water

hydraulic system,” said Ian Cockerill.

Technical Details

Alan Barrows, in charge of day-to-day operations

for Peterstow’s drill production facilities,

said one of the biggest challenges in

adaptation of water hydraulics to modern

industrial applications was a change in

focus from low-pressure, high-flow systems

to high-pressure, low-flow systems. The

primary engineering problem, he explained,

was finding a way to guarantee

constant lubrication of a device’s moving

parts with water.

The solution, according to Barrows, was

to identify how certain materials interact

when lubricated by extremely thin films of

tap-quality water, and then determine the

best methods to machine and finish those

materials as internal drill components. The

Aquapower drill assembly involves

extremely fine tolerances—ranging from 2

μm to 5 μm—for its few moving parts. In

comparison, oil-lubricated machinery generally

has much wider tolerances, in the

30- to 35-μm range.

Even with the fine tolerances required,

the drills aren’t fabricated from exotic

materials, just high-grade aluminum, various

standard engineering-grade steels and

ceramics, said Barrows. Through its ownership

of plastics specialist Dudley

Associates, Peterstow also is looking into

possible substitution of plastic parts where

possible to lower drill weight.

A tour of Peterstow’s drill production

plant in Ngwenya, Swaziland, just a few

miles from the South African border, confirms

that the company is well-positioned,

technically, to produce fine-tolerance

devices. The plant, located on a disused

32-acre industrial site, has been extensively

renovated, is equipped with millions of

dollars worth of modern machine tools and

can perform almost every operation needed

to achieve the required fit and finish quality

with the exception of some heat-treating

procedures that are outsourced. Barrows

said he is currently working on developing

additional capabilities to eliminate any

need to send parts out for treatment.

Even with the plant’s capabilities clearly

evident, the question ‘why Swaziland?’

generally arises in business discussions,

said Barrows. “At this location, we’re geographically

close to our main clients in

South Africa,” he explained. “The border

crossing is efficient and allows us to

receive and send shipments by truck without

problems, and we also have access to

a ‘dry port’ containerization facility in

Swaziland that enables us to ship anywhere

overseas.”

The plant and its opportunities for local

employment, along with community involvement

and charitable work provided by

Peterstow, has brought important business

and social benefits to Swaziland—a monarchy

that achieved its independence from

Britain in 1964—and overall, the operation

represents one of the 10 largest business

investments in the country’s history.

The Market

Peterstow is not the first company to develop

and promote hydropowered rock drill

systems; Wassara, Sulzer and Novatek, a

South African company, have significant

market presence in this sector, with

Novatek in particular strong in the South

African industry, claiming to have well over

1,000 of its gravity-fed or pumped-hydropower

drills in service there. Both Novatek

and Sulzer offer handheld jackleg versions

as well as rig-mounted systems.

Nevertheless, Peterstow’s management

believes the company’s closed-loop technology

provides measurable cost and performance

advantages in comparison with

its hydropower, pneumatic- and electricpower

drill competitors. Peterstow said it

tested 20 of its Aquapower drills at a large

underground mine starting in 2009 and

achieved a high level of success during the

300 drill-hour test with no equipment failures

and no measurable levels of wear. In

its own tests involving drilling standarddiameter

blast holes into 500-m Pa-compressive-

strength granite—about twice the

average hardness of rock found in South

African mines—Peterstow said its drills

routinely outperform conventional drills by

a significant margin.

The company said it has received

expressions of interest from at least two

large South African mining houses, as well

as from other interested parties.

Alan Barrows, executive director of Peterstow Aquapower, examines a piston assembly manufactured at the company’ s plant in Swaziland, while a technician checks another

part for the extremely fine tolerances required by the technology. Shown at right are completed drills awaiting packaging and shipment from the plant.

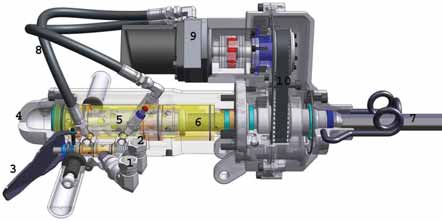

How the System Works

The water is pumped through the drill in

a closed-loop system which continually

recirculates a contained volume of water.

The power pack contains an electric

motor which turns a water hydraulic

pump to circulate the water through the

drill. When the drill is switched off,

water flows through the system at low

pressure.

Water is delivered into the drill

through the pressure line (1). Activating

the Start lever (3) channels the water

into a domed area at the top of the drill—

the accumulator assembly (4) containing

nitrogen gas behind a rubberized

diaphragm. As the dome fills with water,

the gas is compressed. When the water

reaches a pressure level where it can’t

push any harder against the gas, a valve

switches, sending a pulse of high-pressure

water down the center of the drill

(5). Each pulse depresses a piston (6)

which drives the drill bit (7). Water also

flows through a pipe (8) to feed a rotary

motor (9) attached to a drive belt (10)

which turns the drill steel.

Having transferred energy to the piston

and the motor, the water flows out of the

return line (2) and back into the power pack.

|

As featured in Womp 2011 Vol 02 - www.womp-int.com