Mines located at high altitudes, such as the Collahuasi copper operation in northern Chile, shown here,

may be able to capitalize on higher solar radiation levels to power pump systems by photovoltaic cells

rather than dieselgenerated

Finding Energy-effective Solutions for Mine Pumping Systems

Using sun-baked northern Chile as a focus point, the author describes a

computational tool that can identify the most economical method of powering pump

systems—by conventional connection to an existing electrical grid, diesel-driven

generators or solar power

By Francisco Chueco

Solar radiation in this region ranks among the highest in the world, and under certain conditions, photovoltaic (PV) solutions may be a more economic option than traditional power sources. PV cells transform sunlight into electricity, storing it in batteries for later use. Solar PV systems are commonly used for stand-alone applications, require little maintenance and are well suited to remote locations. Due to northern Chile’s geographical position and high levels of sunshine year-round, PV stand-alone systems and PV-diesel hybrid systems could offer a cost-effective solution for some pumping projects in this region.

SKM has developed a software tool that has proven to be useful for generating estimates of investment and annual operation of photovoltaic stand-alone projects, grid extension projects and diesel-fueled power generation for pumping systems in northern Chile. It allows for calculating Present Value of Costs (PVC), comparing three possible solutions for the same pumping project and analyzing the cost-effectiveness for each solution with diverse variables. This article shows the comparison, using data from the area surrounding Calama, Chile, and current prices of energy and fuel.

By various calculations using this tool, it can be shown that PV solutions may be a more cost-effective solution than diesel-fueled power generation or grid extensions to power small pumping systems. For large scale pumping systems, diesel gensets or grid extensions are generally more cost-effective solutions; however, fuel and energy prices and decreasing PV costs can shift costeffectiveness limits and it is important to pay attention to the evolution of these variables.

Using the results generated by the software, it is possible to quickly obtain an estimate of the most cost-effective solution for many pumping projects, allowing users to concentrate their efforts on the most productive wells and the optimal pump-power option from an economic point of view.

There are two independent power systems in northern Chile: the Interconnected System of Grand North (SING) and the Central Interconnected System (SIC). These systems have two types of users: regulated customers with contracted annual power requirements, and nonregulated customers. The latter include large energy consumers such as mining companies, and the price of electricity is different in every case, governed by private contracts between the power provider and customer. The price is usually indexed to the margin of generation. It is important to note the cost of electricity in this area increased dramatically in 2008 in both systems due to a number of factors, exacerbated by regional drought conditions.

The cost of diesel fuel for each of the mining companies in the area is different, but the price trend has been on the rise; in the last nine years the diesel fuel price has swung from $0.33/l to $1.38/l, a variation of 419%. This variability is an important factor in operational costs for users.

Northern Chile has one of the highest levels of solar radiation in the world. For example, in Calama, solar radiation ranges from 4.73 kWh/m2 day in June to 8.84 kWh/m2 day in December. Mines are located at elevations ranging from sea level to thousands of meters above sea level (ASL). For instance, Cía. Minera Doña Inés de Collahuasi is located at 4,400 m ASL. This offers favorable conditions for PV systems because solar radiation increases with altitude and maximum temperatures are moderate, bolstering the performance of photovoltaic modules.

Calculate to Compare

The software tool developed by SKM

can be used to evaluate pumping systems

at any head, daily volume of water

and hours of operation in this region, in

order to identify the most economical

solution. It evaluates the equipment

proposed for any pumping project,

whether powered by diesel generation,

connection to the electrical network or

as a stand-alone PV system.

The user enters basic data (such as daily water volume, head, pumping hours per day, pipe length, pipe material, nominal pressure and the efficiency of the pump) and the tool calculates the hydraulic system and pump power. The Bress Method is applied to obtain optimal pipe diameter using the Hazen- Williams and Darcy-Weisbach formulas to calculate the losses in the pipe.

To analyze a project that would be connected to the electrical grid, the user enters the cost of electricity, available voltage and distance to the nearest grid and the tool computes optimal power line voltage.

For a diesel-powered installation, the tool automatically selects a diesel genset capable of delivering needed electrical supply to the system for pumping. It also estimates the initial investment and the costs of yearly operation for this solution. Nominal power is calculated depending on the altitude of the project. The size of equipment (diesel generators, variable frequency drives, soft starters or transformers) is adjusted, applying the corresponding factors for altitude.

The algorithm calculates the off-grid PV system applying the least favorable month method and it computes a detailed budget of investment considering the main elements such as PV modules, charge controllers, inverters, batteries, fixed structures, wiring, etc. In the least favorable month method, the PV installation is designed to be able to satisfy the electrical requirements for that month. Therefore, in more favorable periods the system will also be adequate. Calculation uses daily average values of consumption and radiation. For large facilities an analysis of hybrid systems (PV-diesel) is recommended and would require further study.

The tool allows for the modification

of different variables. In this article, we

have considered the following variables:

• 24 hours of pumping per day,

• Local information (solar radiation,

temperature, etc.),

• Global co-efficient of loss of 15%,

• Inverter efficiency of 90%,

• Depth of discharge of the batteries

of 70%, and

• Estimated cost of $1.50/Wp for thinfilm

modules.

Running the Numbers

For any solution analyzed, the tool calculates

the Present Value Cost (PVC) as

described in the equation shown below.

PVC is the value of investment costs,

operation and maintenance throughout

its useful life at present value, allowing

for comparison of the alternatives.

Where:

Cn = annual costs

I = initial investment

N = periods or years

r = discount rate

This software tool is useful for comparative analysis; it uses Standard Cost Investment values of any equipment and analyzes a large number of projects for wide-ranging variables. It presents a three-dimensional view. In one of the axes, the difference between the PVC of two possible solutions is shown. In the other axis a range of pumping power (kW), distance to electrical grid (km) and electricity prices ($/MWh) or fuel prices ($/liter) is shown. It is possible to determine the cost-effective limits in the comparison of each solution. It is also possible to obtain estimates of initial investment costs and the annual operational costs of each project, and to calculate PVC. Each solution for powering a pumping system is compared directly in these three-dimensional views.

The user can change parameters to get results for a particular area, to take into account the proximity of an electrical grid, or to consider variations in energy and fuel costs. Electrical losses in power lines are accounted for. In general, overhead lines are designed so that their ohmic losses do not exceed 7%, and this value is considered the reference.

Making the Choice

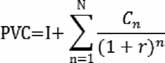

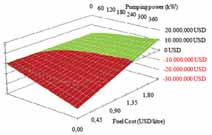

Photovoltaic vs. 13.2-kV grid extension

Figure 1 shows the cost-effective limits

of a PV solution versus a 13.2-kV grid

extension considering $250/MWh as

energy cost. In the light colored zone of

the chart, the PV solution is more economic.

For small pumping systems with

long distances from the well to the

existing grid, a PV solution is more

cost-effective. As the distance increases,

the pumping power at which a PV

solution is more cost-effective is higher.

For instance, when the pumping power

is 20 kW and the distance from the well

to the existing grid is greater than 8.5

km, a PV solution is more cost-effective

than a 13.2-kV grid extension.

At higher electricity prices, a PV solution is cost effective in more cases. Figure 2 shows the sensitivity of the best option to electricity cost in a case where the well is 5 km from the nearest grid. In this case, even if energy is free of charge, a PV solution is economically better than a grid connection up to 4.3 kW. If the price of electricity is $350/MWh, PV would be more costeffective up to 27 kW of pumping power.

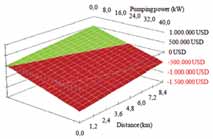

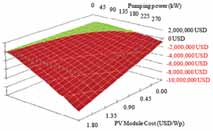

Photovoltaic vs. 23-kV grid extension

A PV solution is more cost-effective

than a 23-kV grid extension project up

to 85 kW of pumping power and 27 km

from the well to the existing grid.

Figure 3 shows the sensitivity of the

best option to electricity cost in a case

where the well is 20 km from the nearest

grid. In this case, even if energy is

free, a PV solution is economically better

than a grid connection up to 24 kW.

Further analysis shows that at a given

distance, as the PV modules are cheaper,

the range of pumping power for

which the PV option is advisable is

greater. However, even if PV modules

were cost-free, a grid extension is more

favorable for projects involving pumping

power higher than 215 kW.

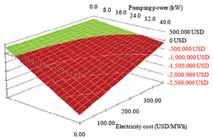

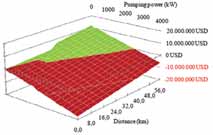

Photovoltaic vs. diesel powered

generation

At sites where grid extension is not feasible,

a pumping system can be driven

by a diesel genset or PV system. In

Figure 4, the light colored zone indicates

the area in which a PV stand-alone solution

(lower PVC) is recommended. For

instance, when diesel fuel price exceeds

$1.20/l, and considering the solar radiation

in the area, PV systems are more

cost-effective for pumping power requirements

up to 125 kW. Each case

study analyzed considers the fuel price

as an input. An annual inflation rate of

3% has been applied for its useful life.

Figure 5 shows the sensitivity of profitability of a PV solution based on the cost of thin-film PV modules, considering a fuel cost of $0.85/l. For power requirements greater than 185 kW, diesel generation is cheaper even if PV modules were cost-free. Considering the current costs of fuel, PV power for projects requiring up to 20 kW is economical.

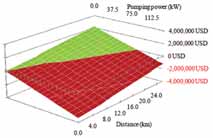

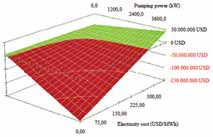

66-kV grid extension vs. diesel powered

generation

SKM also analyzed projects based on

available electrical grid voltage levels versus

power from diesel gensets. An example

is shown here where the available

grid power is 66 kV. In this case, the

cost-effective limit is shown in Figure 6. For instance, when the grid is at a distance

of 40 km, it is more profitable to

install diesel generation up to 1.8 MW,

with prices of fuel and electricity being

$0.85/l and $250/MWh, respectively.

With a well located 30 km from a 66-kV overhead line, for example, a project using diesel power generation up to 1.35 MW implies lower PVC (Figure 7). At this distance and with a fuel cost of $0.85/l, an asymptote—a line that approaches a given curve arbitrarily closely but never touches—near $275/MWh is shown on the graph. If the electricity cost is higher than this value it will be more economical to install a diesel system.

Acknowledgement

The author is grateful for the support of

SKM’s Bruce Sinclair Scholarship and

Technology & Innovation Program,

which financed these studies.

Francisco Chueco is an electrical engineer and European Master in Renewable Energy, based in SKM’s Santiago, Chile, office. Published by permission of SKM, this is an abridged version of the original paper; readers may obtain a copy of the original, including all text, tables and references, by contacting mwhaley@skm.com.au.