Swedish contractor NCC is responsible for pre-split drilling at Boliden’s Aitik open-pit mine.

The Buzz Is Back

E&MJ’s annual update looks at the newly expanded Aitik copper operation—as well

as other on-the-ground developments in iron ore, nickel and gold—and reviews the

latest advances from Scandinavia’s mining and processing technology leaders

By Kyran Casteel

Full Steam Ahead for Aitik

Boliden’s largest mining investment—the

expansion of its Aitik open-pit mine in

Lappland—is beginning to bear fruit as

both production volumes and productivity

improve. The expansion, which actually

came on stream in April this year, aims

to double the amount of ore mined from

18 to 36 million mt/y by 2014, enabling

the life-span to be extended from 2016

to 2029. So far everything is going

according to plan with the operation firmly

on track to meet its short and long

term goals, reported Mine Manager Patrik

Gillerstedt.

Aitik’s progress is especially interesting considering the copper ore is of extremely low grade—only about 0.25%—yet the efficiency of production means it can be mined profitably for many more years to come. Much of the expansion and efficiency work undertaken has focused on stepping up the throughput rate at the mine’s two autogenous milling lines. This has been done primarily by meticulous optimization of drilling and blasting techniques all of which are geared to meeting specific requirements for rock fragmentation.

“We are using autogenous milling and ideally you want to get a few large rocks and the rest of them small,” said Gillerstedt. “In reality of course you also get a lot of medium sized rocks you don’t want. The drilling and blasting is extremely important for us to get right.

“We have now succeeded in fine-tuning our operations, particularly when it comes to the blasting, where we have put a lot of effort into establishing the right powder factor. The result is increased throughput in the mill by an average of about 7%,” said Gillerstedt.

Big operation, big equipment

Everything at Aitik is on a big scale. The

pit, located outside the town of Gällivare,

is approximately 3,000 m long, 1,000 m

wide and 400 m deep. And in keeping

with this, the production drilling fleet is also the largest on the market consisting

of four Pit Viper 351 rigs as well as a

SmartROC D65 (formerly SmartRig), all

supplied by Atlas Copco.

The Pit Viper fleet is operated by Boliden while the SmartROC D65 is operated by the Swedish contractor NCC. The Pit Viper rigs, which account for the majority of the production drilling, are meeting their target of 27 drilled meters per hour while the SmartROC D65 is successfully drilling the pre-split holes on the benches. On the SmartROC, the Full Drill Cycle Automation option has proven very popular as the operator can now prepare material on the bench while the rig finishes the hole by itself. A second SmartROC D65 was expected to arrive on site during September.

All of the rigs are equipped with the same Atlas Copco-developed RCS rig control system which enables drill and blast plans to be loaded directly into the rigs’ computers. On the Pit Viper this is done via the mine’s wireless LAN. In addition, the system provides a high level of automation such as GPS hole navigation—a major contributor to hole depth quality—remote tramming and auto-drilling as well as autolevelling in the case of the Pit Viper rigs.

Boosting efficiency

Various tests are also under way at Aitik to

further boost efficiency in the future.

These include the use of low-impact DTH

percussive hammers from Secoroc in combination

with the Pit Viper’s rotary drilling

action to increase penetration rate, and of

the rig’s auto-tramming feature which

enables it to tram to the next hole or holes

based on the planned path. This allows

the operator to auto-locate each hole on

the bench.

“It’s also important to get the right hole depths. We need smooth blasting at the bottom of the holes so we get good flat surfaces for loading in order not to jeopardize the safety of the big trucks and other equipment during loading. When the drillers drill to the right depth and not too deep it also means there will be less loose rock for them to drill through when they get down to the next level,” said Palo.

“Accuracy is extremely important for the fragmentation. We must ensure that we get the hole in the right place and the more accurate we can be, the tighter we can make the pattern. That way we can actually save drill meters and drill fewer holes,” said Gillerstedt.

Favorable conditions

Mining of such low-grade ore is seen as a

big challenge by the miners at Aitik and

Gillerstedt maintains the current productivity

level is comparable with that of the

world’s most modern mines, irrespective

of ore to waste ratio. “Admittedly we get a

little help from nature,” he said. “We are

fortunate in having good rock conditions

here which enable us to have really steep

slopes—47° on the footwalls and 52° on

the hanging wall—which means we don’t

have to mine too much waste rock.”

Another concern for the mine, which will eventually be 600 m deep, is to limit the distances for rock haulage in the mine area and from the bottom of the pit to the surface. This will limit the number of trucks needed and reduce fuel costs. For this reason the mine has installed a system of tunnels and electric conveyors that move the ore to the mill. Using all methods of transport, more than 80 million mt of rock is being moved per year.

“Our big challenge is to have a very low cost per ton of metal and that means we have to be super efficient. We are pretty confident that we will be among the top three on the cash-to-cost list of all the mines in the world,” Gillerstedt said.

“Fire in the hole” is how LKAB announced the inauguration of Gruvberget, near Svappavaara. This is Europe’s largest iron ore project and the company’s first new iron ore mine for 50 years.

Mining, by the Kiruna-based LKAB subsidiary KGS, started not many days after Sweden’s Environmental Court granted the project an environmental permit. LKAB had already carried out test mining of 50,000 mt of ore from the deposit, as allowed by a permit which the Norrbotten County Administration Board had granted to the company’s magnetite subsidiary Minelco in April 2008.

The total resource at Gruvberget is estimated at 25 million mt magnetite plus about 50 million mt of hematite that will not be mined for awhile. The initial reserve within the Gruvberget pit is about 12 million mt. LKAB is investing about SEK240 million in the project which will employ 30–40 people and supply the Svappavaara pelletization operation with 2 million mt/y of ore. Cliffton, a subsidiary of the large construction company PEAB, has a haulage contract.

Assuming pending environmental permit applications are successful, two more open pits will be developed in the Svappavaara area. An open-pit at Leveäniemi, which was closed during the mid-1980s downturn, will be drained and at Mertainen test mining will be carried out. Together the three deposits contain about 300 million mt of iron ore grading 40%–55% Fe. The new mines will help LKAB to make full use of the process plant capacities available at Malmberget, Kiruna and Svappavaara and thereby raise output of finished iron ore products by 10 million mt to 37 million mt. However these mines will feature a production structure that will allow LKAB to mine them only when their output is needed, explained Per-Erik Lindvall, senior vice president technology and business development, providing inhouse swing production.

More Northern Nickel

Kevitsa got the go-ahead...

In November 2009, First Quantum

Minerals (FQM) returned to the deferred

decision making process on the proposed

Kevitsa nickel-copper-platinum group elements

(PGE) mine in northern Finland and

thereafter announced the project would

proceed. “We look forward to applying our

expertise to the development of one of the

world’s major undeveloped sulphide nickel

deposits and one of the largest mineral

discoveries in Finland's history,” said

Philip Pascall, chairman and CEO of First

Quantum. “We are very pleased to be able

to confidently approve the development of

the Kevitsa project within just 18 months

of the acquisition of the project.”

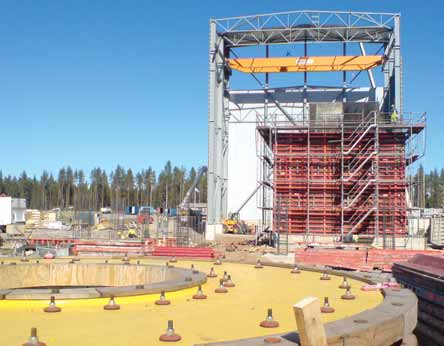

The project, located approximately 142 km north-northeast of Rovaniemi, the capital of Finnish Lapland, has all material mining permits and detailed engineering started before year-end, with commercial production targeted for mid-2012. Measured and indicated resources, as of November 2009, were estimated at 165 million mt grading 0.30% nickel; 0.27 nickel sulphide; and 0.42% copper; using a nickel cut-off grade of 0.1%.

The open-pit mine is planned to employ large-scale electric-powered mining equipment to deliver ore to the primary gyratory crusher. Process facilities have been designed for 5 million mt/y with built-in expansion capabilities. After crushing the ore will be autogenously milled prior to the two-staged flotation process. Two concentrates will be produced— a copper/gold concentrate, and a nickel concentrate that will contain the majority of the PGE. Off-take arrangements for the separate treatment of both concentrates will target international as well as local smelters.

Life-of-mine cash operating cost was estimated at approximately $2.50/lb nickel, net of by-product credits, assuming a long-term nickel price of $6.75/lb and copper prices of $2/lb. The company expects to employ a workforce of approximately 200 during commercial operations at the open-pit mine which is expected to operate for more than 20 years. Financing for the $400-million project is expected to be a combination of equity and loan, including Nordic institutions.

...and is on schedule

In late July 2010, FQM reported on-site

construction had commenced, with

approximately 75 construction personnel

currently on site; BNP Paribas and

Standard Bank of South Africa have been

jointly mandated to arrange a debt facility;

and agreement has been reached that the

Finnish government will reimburse the

company for the cost of constructing the

access road to the mine site—which was

started in 2008 and recently completed

by Finnish contractor Veljekset Karjalainen.

The government has also committed

to contribute financially to other infrastructure

projects such as power and water

services.

The ongoing drill program continues to return positive results, FQM said, and a new mineral resource model and reserve optimization is currently in progress and is expected to be finalized before year-end 2010. Several holes have been extended below the current open-pit resource and demonstrate mineralization continuing at depths of over 900 m, encouraging the examination of potential options for bulk extraction from underground. Drilling emphasis has now moved on to exploration for massive sulphide lenses on the northern and eastern contacts of the Kevitsa intrusion where recent geophysical surveys have defined several encouraging targets.

Kevitsa development is being managed by First Quantum’s group project office in Perth, Australia, with Fluor providing basic engineering. Detailed design is being handled by a project team based at the Helsinki office of Kevitsa Mining AB, FQM’s local management subsidiary, working with a counterpart team from Pöyry, a Finnish-based global consulting company. The FQM team is led by Stuart Sankey and the Pöyry one by Tomi Arasola.

Kevitsa Mining has awarded major construction jobs to Finnish contractors. Structural steelwork fabrication and erection is being undertaken by Naaraharju, the erection of a 110-kV power line by Empower and the plant site HV switchyard by Vaasa Engineering. There are two contracts for plant site earthworks and concrete works including foundations for mine production facilities and plant, which Lemminkäinen Talo has commenced and should complete in spring 2011. About 100 Lemminkäinen personnel will be involved and the total value of the construction works is approximately €10 million.

Essentially all long-lead equipment orders have been placed, with deliveries programmed to suit the construction schedule. FQM contracted Outotec first to deliver the grinding mills and, later in 2010, to deliver 14 TankCell 300 units and 54 smaller TankCell flotation cells plus thickeners and filters for nickel and copper concentrate recovery. Outotec is maintaining scheduled manufacturing progress, FQM reports.

Belvedere restarts Hitura

Late in July, Vancouver-based Belvedere

Resources announced the successful

restart of its 100%-owned Hitura nickel

mine in Finland. First concentrate has

been produced, well ahead of the scheduled

restart of the mine in August and

both mine and mill are ramping up to full

production. “We are very pleased with the

production of first concentrate from the

mine. The re-commissioning of the mill

was the last remaining milestone to the

restart of the Hitura mine. The restart of

the mine so soon after the acquisition in

February 2010 is due to the hard work and

commitment demonstrated by our staff

and contractors. The company has now

moved to a new level from explorer to nickel

producer and looks forward to continuing

to further develop its Finnish nickel

and gold assets in the future,” said CEO

David Pym.

Belvedere expects to build up to the full production rate of 45,000 mt/month by January 2011. Operations are forecast to produce approximately 2,100 mt of nickel in concentrate in the first 12 months. For the first 18 months of production, Belvedere has a fixed price offtake agreement for its nickel concentrates.

The mining lease for the Nordic Mines AB Laiva gold mine project, which is 15 km south of the Port of Raahe in Finland, was granted in September 2008, two months after Nordic listed on the Nasdaq OMX Nordic Exchange. The planning permit from Raahe city followed in October 2008. The environmental permit came through in November 2009. A full feasibility study was completed in first quarter 2010 and was examined and signed off by Hatch in March. It showed the planned operation to be profitable even at gold prices far below present levels.

On July 22, Nordic secured all necessary funding for completing the project, CEO Michael Nilsson told E&MJ in Stockholm. Nordic Mines now has full funding for budgeted investments and working capital in place to start gold mining.

Geology

Nordic Mines started as a prospecting and

exploration company and has a portfolio of

six project areas in Sweden and Finland

but has focused on Laiva for some time.

One of the six co-founders of, Nilsson is

well versed in Finnish gold mining, having

worked at the Pahtavaara mine before the

demise of Scan Mining led to its purchase

by Lappland Goldminers.

Laiva had been an Outokumpu project in the 1980s before passing to a contracting firm when the Big O sold off most of its mining assets, Nilsson explained. Nordic Mines bought it as an exploration project and has been able to continuously build up the resource using what the company terms systematic 3-D geochemistry to assess the mineralization in the bedrock below a thick covering of glacial moraine. This method involves systematic surface sampling and analysis, followed by reverse circulation and core drilling, sampling and analysis, using vertical drilling and later angled drilling.

The exploration program increased Laiva resources from 100,000 inferred ounces in June 2005 to 1,023,000 oz measured and indicated gold plus 270,000 oz inferred by 2009, based on 53,000 m of drilling. Subsequent exploration for the full feasibility study established proven and probable ore reserves of 11.7 million mt averaging 1.9 g/mt gold, and a further 4.9 million mt of measured and indicated resource with an average 1.8 g/mt gold as of the end of March 2010. This makes Laiva one of the largest gold deposits in the Nordic region. Nordic has two drills of its own for soil sampling down to 50 m but most of the drilling has been done by contractors including Pöyry and Kati.

CSA Global has been responsible for resource evaluation and mine planning, with Lapin Vesitutkimus undertaking environmental studies. Although drilling has gone down 300 m in places the resource figures are based only on drilling to a depth of 150 m, Nilsson pointed out. The measured, indicated and inferred resources were calculated using kriging in a block model. Within the borders for measured and indicated resources the optimal open-pit volume was defined by Whittle optimization. Based on this exercise CSA created a mine plan and the mineral resources in this production plan were reclassified as ore reserves.

There is also excellent potential for future increases in resources at Kaukainen and Musunneva southeast and south of Laiva, where 981 holes were drilled in 2009, Nilsson said. Exploration in the Laiva area is being extended in 2010 and programs are starting at other Nordic Mines prospects, particularly Tormua, which is east-northeast of Laiva and 60 km northeast of Soumussalmi near Finland’s border with Russia, and in Sweden at the Fjälltuna gold project between Åsele and Fredrika, west of Umeå.

Mining and processing

The deposit is wide and well suited to largescale

open-pit mining at a planned ore:

waste ratio of about 1:4. Test mining and

pilot scale beneficiation showed that the

ore can be recovered by traditional methods,

with high recoveries at low unit costs.

The feasibility study mine planning covers the period 2011–2017 and envisages three pits with the largest on the north side of the deposit. Laiva will mine 10-m-high waste benches and 5-m ore benches using pattern blasting. The 200- mt and smaller excavators will selectively load to 100-mt-capacity haul trucks. Nordic Mines personnel will do the mining with help from specialist contractors, said Nilsson.

The processing element of the feasibility study and financial calculations were carried out by Outotec. Two 250 mt/hour Outotec autogenous mills will grind to 175 micron with cone crushers in circuit for handling oversize. A 170-kW Metso mill will regrind part of the output to 45 micron. A mobile crusher has been used for mill test feed but installation of the Metso stationary crushers was the next job on the schedule at the time of writing.

Flash flotation will be used to extract 80% of the sulphide material for storage in a lined pond. The regrind milling circuit will separate out a small fraction suitable for gravity separation in a Falcon or Knelson concentrator and the overflow will go to the CIL tanks. An Inco Process cyanide destruction system will treat the outflow and the tails will go to a paste plant that will also recover water for recycling. The end-product will be doré gold, with a target initial production rate of 118,000 oz/y based on 86% gold recovery to be followed by an expansion.

The Finnish Government has decided to contribute €1.3 million for infrastructure investments.

Construction progresses

Late in 2009, Nordic formed a whollyowned

subsidiary, Nordic Mines Oy, in

Finland and work started at the mine site

during the first quarter of 2010. The construction

program is being overseen by

Ahma Engineers, a company with offices

in Helsinki, Oulu and Rovaniemi and

employing. Around 100 people which has

worked on the Kittilä and Pampalo projects.

Mine production should start in the

second quarter of 2011.

In August 2010, Metso’s Mining & Construction Technology segment announced it will meet a €30-million order for a range of equipment for the gold processing plant, plus services including supervision, start-up and commissioning which should start in August 2011. The equipment includes the regrind mill, pumps, flotation equipment, crushers and screens, plus steel structures, piping and a plant electrical, instrumentation and automation package. The plant will have a processing capacity of 2 million mt/y dry gold ore. The outer structure of the mill facility will be completed by the end of October so that construction can continue through the winter months.

Nordic Mines has been run with a small core staff—just seven people working in Sweden and five in Finland during first quarter 2010. This team is seemingly well on the way to achieving the company’s stated aim of becoming a leading European gold producer. From the outset Nordic has also expressed the intention to be a role model in respecting the environment and has deposited €900,000 with the Environmental Agency for future environmental commitments.

Sydvaranger: rectification on track

Shortly after publication of the previous

Scandinavian Mining report last October

the Northern Iron Ltd. (NIL) subsidiary

Sydvaranger Gruve started iron ore production

at the reactivated operations in

and near Kirkenes in northern Norway. In

order to make the most of the then-strong

demand for iron ore NIL had adopted a

fast track project development strategy

using as many of the existing facilities as

the company’s technical advisors

approved.

In fact, start-up had been delayed, partly by the late delivery of new equipment. In the market situation arising at the time this was not a major issue— China’s re-whetted appetite for iron ore was just starting to push prices up after the financial crisis and they continued to rise in 2010. But once concentrate production and loading did start in the fourth quarter of 2009 Sydvaranger could not deliver the planned tonnage rate of 2.8 million mt/y, nor did the product meet the specifications on which NIL’s long-term offtake deal with the steelmaker Corus was based. These problems stemmed at least partly from the failure of some of the older equipment to perform as expected.

The main restrictions on throughput were: the filters could only attain 75% of nameplate capacity without adversely affecting concentrate quality and failing to dry the material to below the required transportable moisture limit of 8%; fine crushing could only reach 80% of rated throughput; and secondary magnetic separation adversely affected product quality if operated at over 80% of capacity. Quality was also reduced by limited secondary grinding capacity and the lack of concentrate screening equipment. When running at necessary rates the plant could not screen out coarse particles and these not only depressed the iron content of the concentrate well below the 67% Fe planned, but also raised the silica content well above the intended 3%.

NIL was able to sell some of the concentrate, which was price benchmarked to Indian 63.5% fines, because some Chinese customers were happy to pay prices discounted for the lower iron and high silica. But this was only a temporary solution as Corus was only prepared to start taking its shipments when the quality improved. NIL drew up a production and quality improvement plan intended to get close to the original tonnage and specifications by July 2010 and reach them in early 2011. NIL and Sydvaranger Gruve have also taken various steps to finance the necessary expenditure, budgeted at $25 million.

The prescription was more grinding capacity, new screens to remove coarse particles and a new effective filter. Specific projects included: refurbishment of existing screens, refurbishment of a fifth secondary mill, a new screen for the secondary and tertiary crushers, installation of additional magnetic separators, installation of an additional filter, all to be completed by mid-year, and installation of new concentrate screens in January 2011. Execution started in February 2010.

Ramp-up on schedule

Meanwhile, mining progressed satisfactorily,

helped by the scheduled arrival of a

third large drilling rig. Although ramp-up

to the 75% of nameplate tonnage was

slower than expected, by April mining was

exceeding the planned output rate. In the

second quarter of 2010, Sydvaranger

mined 978,000 mt, 17% more than in

the previous three months.

The rectification work and other issues did limit concentrate output but most of the significant components were commissioned by July when the new pressure filter started up. It achieved 24/7 operation at designed production rates and moisture levels. In July also a 77,475-mt trial shipment was sent to the Corus plant at Ijmuiden in the Netherlands. In August crusher screen optimization was completed and the fifth secondary was to be commissioned. Stack sizers should be ready, ahead of schedule, in late October. NIL expects the whole rectification program to be completed in January 2011 when the new concentrate screens are due to be installed.

Concentrate sales April through June totaled 415,000 mt, which represented a 20% increase over the first quarter. And the average sales price increased by no less than 71% relative to the January– March average. Recent concentrate production has been above 64% Fe and under 10% silica—still a way to go but getting there.

Late delivery of the primary crusher required the use of mobile crushers to feed the secondary/tertiary crushing circuit that supplies the material for agglomeration and bioleaching. This slowed the early stage of heap building and leaching. When the primary was installed the crushing and materials handling system could not consistently throughput at the designed rate, so heap building was too slow to supply sufficient pregnant solution for the metals recovery plant when processing started in October 2008. This and other factors led to re-precipitation within the first heap section which tied up metal and could make it difficult to transfer this section to the secondary heap when the time comes. Even so the first delivery of nickel-cobalt sulphide to Norilsk Nickel’s Harjavalta refinery was made on February 19, 2009. Zinc is sold through agents and traders.

Starting over

The crushing problem was sufficiently

severe that Talvivaara decided the system

must be redesigned. The new configuration

would have an extra crushing stage

and capacity would be increased to

60,000 mt/d. Provision was made for the

addition of two extra tertiary crushers if

ramp-up to this rate was not achieved. The

new system was completed in September

2009 at which point the processing operation

was effectively restarted. The cost of

this exercise was not a major issue but the

limitation on metals output was, especially

as by this time the banks were not being

abundantly helpful. Consequently Talvivaara

has had to progress along a huge

learning curve, Perä considered.

The link from the mine to the main railway system was also completed in September and electronic operation of the link was approved in November. The mine haulage fleet was increased from three trucks in October 2008 to four in May 2009. Two more were delivered in the fourth quarter, then another two plus a second excavator in 2010, doubling the original fleet. Currently, one excavator loads ore and the other loads waste rock, mainly used for building the foundation for the secondary bioleaching heap. The company carried out 22,500 m of exploration drilling in the year, focused on four targets. The geology department was demerged in mid-2009 to form Talvivaara Exploration Oy.

In 2009, the mine blasted 10.8 million mt of ore and 4.4 million mt of waste, with the post-crushing-upgrade fourth quarter contributing 3.5 million mt ore and 1.5 million mt waste. Some 8.5 million mt ore was stacked on the primary heap sections, mostly in October through December. Heap section 2 was completed in early January and initial re-precipitation stopped in early February thanks to improved aeration. The third section is also performing well, Perä said. The plant recovered 1,526 dmt of nickel sulphide containing 735 mt nickel through the year with 410 mt of the nickel being extracted in the fourth quarter. Zinc sulphide output was 5,271 dmt in the year, 3,827 dmt in October through December.

In conjunction with the crushing upgrade, Talvivaara also designed and proposed an overall expansion to raise production capacity from 33,000 mt/y nickel and 60,000 mt/y zinc to 50,000 mt/y nickel and 95,000 mt/y zinc. Copper capacity would rise to 15,000 mt/y and cobalt to 1,800 mt/y. Despite the ongoing technical issues in early 2009, this scheme was well received in the market, Perä said. Meanwhile, construction of the second metals production line was accelerated.

The future galvanized…

In 2010, having got the materials handling

system working properly, Talvivaara

was able to start optimizing the bioleaching

process, said Perä. Production targets

for the year were set at 30,000 mt nickel

and 50,000 mt zinc. To counter the unacceptable

frequency of lost time accidents

in 2009, the company introduced departmental

competitions to incentivize safe

working.

However, Talvivaara soon ran into a new technical problem. During the first quarter the hydrogen production plant for the metals recovery line experienced catalyst problems because of impurities in the propane, resulting in a three-week shutdown in February. This did nothing to ease the company’s project financing position, which had been significantly weakened by the problems experienced during 2009. Also in the first quarter Perä and his team were able to secure an excellent deal with Nyrstar NV, the Belgium-based zinc producer. This was a zinc streaming agreement that monetized Talvivaara’s second major metal output, covering the delivery of all the company’s zinc concentrate to Nyrstar until 1.25 million mt has been supplied. Nyrstar paid $335 million for this secured supply stream and will pay €350/mt of contained zinc as an extraction and processing fee. Talvivaara is also entitled to purchase up to 250,000 mt/y of sulphuric acid from Nyrstar—about half the amount the operation needs.

This deal pretty much fixed Talvivaara’s financial position as the $320-million Project Term Loan Facility could be repaid in full and early, which in turn enabled the company to close its hedging positions with net proceeds of €45 million. The stream also boosted market confidence in the project as Nyrstar, not surprisingly, evaluated the operation very thoroughly.

Production also started to pick up despite other technical issues, including the need to improve gas scrubbing in the precipitation reactors. From 410 mt in October through December 2009, nickel output increased to 628 mt in the first quarter of 2010 and to 2,729 mt in April through June, with more than 1,200 mt of this being recovered in June. The second production line was successfully and smoothly commissioned in this month. Talvivaara now forecast total 2010 production at 15,000–25,000 mt of nickel, depending on how much re-precipitated nickel can be recovered from the first heap section. The company also said it expects to achieve the expanded production rate of 50,000 mt nickel in 2012.

… and energized?

Talvivaara is now considering some other

options, while continuing process and

plant development in cooperation with

Outotec and Norilsk Nickel. For two years

the technical team has been researching

the feasibility of recovering the uranium

content of the ore. A breakthrough could

allow recovery of about 95% of this by solvent

extraction, giving an estimated output

of 350 mt/y.

Manganese recovery by electrowinning has been shown to be feasible but the volumes involved would require marketing by a very skilful partner. Another line of research has been bio-iron removal from the leach solution by local bacteria.

Pekka Perä confirmed the importance of a €100-million, three-year revolving credit facility agreed with three Nordic banks on June 30, 2010. Intended for general corporate purposes, this arrangement marked the financial completion of the project and concluded Talvivaara’s transformation into an operating entity, he said.

At Kittilä the risk factor was the nature of the ore, Haga explained. The feasibility study identified the presence of chloride in apatite and chlorapatite minerals contained in the ore and also organic carbon. The plant was designed with a flotation circuit that removes 30% of the carbon but the actual effect of the chloride in the process was not fully anticipated. In practice gold chloride is created in the autoclave, builds up in the circulating process solution and passes through the CIL process to tailings. This preg robbing, together with remaining carbon in the process solution, restricted gold recovery during ramp-up. On the other hand the process plant is mechanically excellent and can run at over the rated throughput. This has enabled Kittilä to compensate for the restricted recovery rate although only to 71,838 oz in 2009, well short of the target output of 150,000 oz/y. Total cash costs were above expectations at $668/oz.

In the first part of 2010 a longer than expected mill shutdown reduced gold output but metallurgists were able to address the recovery problems, using oxidation chemistry to avoid gold chloride formation—by varying pressure, temperature, oxygen and acidity levels in the autoclave, for example. Stabilizing agents are another weapon and reducing the chloride in the process solution before autoclaving is another option. Bottle roll tests show that partial chloride extraction can maintain gold recovery at well over 80% with a feed containing 2.5% or less total organic carbon. In June, July and August this year recoveries improved significantly, Haga said.

Consequently AEM management in Canada is happy with the mine’s contribution to the company’s overall gold production build-up that has transformed AEM from a small company 10 years ago to a substantial gold supplier with an output of 492,972 oz in 2009, Haga pointed out. AEM also opened a new mine, Meadowbank in northern Canada in June.

Meanwhile mining is proceeding according to plan, with the deposit providing no surprises so far. AEM (Agnico-Eagle Finland, to be precise) is mining two open pits: Suuri, close to the offices and process facilities; and Roura to the north. Kittilä is now using down-the-hole drilling for openpit production but has retained one tophammer rig for pre-split drilling. Maxam is producing explosives at the matrix plant on site and delivering them to the holes by truck. However, production at Suuri will start to decline late this year, and Roura will be the main open-pit in 2011 while a new small pit, Etela south of Suuri, will add to gradually declining output until surface mining stops in 2013.

Underground development enabled mining of two stopes in first half of 2010. Stopes will initially be mined in three areas down to the 600 level, mucking and haulage is being done by a contractor. AEM intends to do all the mining in future but will require contractor assistance for some time yet, Haga said. Anticipated mine life is now 23 years.

Tailings are piped to two ponds. In Pond 1 AEM neutralizes flotation tailings for recycling to Pond 2 and clean water is discharged to the river system – the Seurujoki river is nearby. Pond 2 handles the CIL tails after they have passed through the Inco Process cyanide destruction unit, as required by EU regulations. Process water is recycled from this pond but there are no discharges to the environment. A new tailings containment area is under construction.

The main long-term focus is on expanding the mineral resource, Haga said. In 2009, exploration increased gold resources by 25% and the company has allocated €16 million for drilling in the mine licence area during 2010. A contractor has two rigs exploring underground and there are 10 on surface, also operated by contractors, drilling to depths of 800–1,200 m. The main purpose is to convert resources in the Suuri area and at Rimpi, north of Roura, to reserves.

The regional exploration budget is €5.5 million for testing the whole mineralized structure. In addition, some 400 km to the south AEM has another company in the early stages of exploration. Agnico is also looking for new exploration options, including through buy-ins.

Meanwhile Kittilä, which now employs 500 people, was able to run on cash earnings in August and 2010 gold production could be 147,000 oz. Thereafter output should reach 150,000 oz/y at total cash costs in the $520-550/oz range, Haga said.

Reviewing the Situation

While the operations discussed above are

under construction or ramp-up there is a

considerable Nordic pipeline of iron ore,

nickel, gold and other mineral projects looking

to make progress in the near- to medium-

term. E&MJ talked to four Swedish

hopefuls: one, IGE Nordic, planning to produce

nickel and cobalt and three with iron

ore projects—Dannemora Mineral, Northland

Resources and Grängesberg Iron.

IGE Nordic seeks feasibility study finance

A subsidiary of the Oslo listed IGE Resources

AB group (IGE), IGE Nordic is currently

wholly focused on the Rönnbäcken

nickel project (RNP) in the upper Umeå

river valley close to Sweden’s border with

Norway. In Stockholm, CEO Fredric Bratt

and Manager Operations Development Lars

Carnerud outlined the present state-of-play.

Based on the extensive international nickel industry experience of the IGE Nordic management team, Bratt and Carnerud are convinced they have a good, internationally competitive project. Although the grade is low, the mineralogy is very favorable thanks to the presence of unusually rich nickel sulphide minerals such as Heazlewoodite (71%–75% nickel) and Millerite (61%-65% Ni, 2%-5% cobalt) in addition to the conventional Pentlandite (38%-40% Ni, 2%-6% Co). According to the company, RNP has very low potential for acid drainage, excellent existing infrastructure and offers potential economies of scale similar to those achieved by New Boliden at Aitik.

What IGE Nordic does not have at the time of writing is funding for the pre-feasibility study which is the next key step for the RNP. For this reason, IGE recently hired Hatch Corporate Finance to execute a private placement to finance the PFS in exchange for a stake in the project. Meanwhile, Sweden’s Norrlandsfonden, established to provide risk capital for small and medium-sized companies in the country’s five northern counties, is providing a SEK 5 million ($600,000) convertible loan for on-going exploration and development, thereby endorsing the RNP.

IGE also entered into a strategic partnership with the Mitchell River Group (MRG) in June 2010, whereby the Perth, Western Australia based company will provide nickel development expertise in return for an option to acquire 10% of the RNP. Bratt said that he had contacts with MRG in his previous position at Falconbridge International and was impressed by MRG’s ability to realize the Sally Malay (Australia), Munali (Zambia) and Santa Rita (Brazil) nickel ventures from early stage exploration through feasibility studies to production.

Bratt and Carnerud explained, given that PFS funds become available, the current RNP timetable has the study finalized in first quarter 2012, approval of the Environmental Permit application and completion of a Bankable Feasibility Study in the second quarter 2013, construction starting in mid-2013 and commissioning in the second quarter 2015.

Iron in line

At the Dannemora Mineral AB office in

Danderyd, Stockholm, CEO Staffan

Bennerdt confirmed the company had put

the brakes on its project to restart production

at the Dannemora mine near Österbybruk

during the financial crisis. But, he

went on, the management team had used

the time to do its homework thoroughly,

assisted by Micon consultants who presented

a technical, legal, environmental

and financial assessment of the project in

December 2009. Mine drainage was completed

in February, a permanent dewatering

system is being installed and Dannemora

is now ready to enter start-up.

In the fourth quarter of 2009, the delayed trial shipments to potential customers had started.

In the expectation of favorable trial results, and having secured funds through three share issues on the Oslo stock exchange, Dannemora is now recruiting a full team for production start-up one year after a “go” decision, with ramp-up to 1.5 million mt/y over 18 months while the hoisting shaft is refurbished. Bergteamet is driving a ramp decline from the existing ramp to the main future production level. Dannemora has received bids for the new equipment needed and is considering leasing from key mobile equipment suppliers. Bidding is under way for construction of the process plant which will include crushing, screening and dry magnetic separation to yield 55% lumpy ore, 45% fines. The total operational workforce is expected to be 120 people.

Cash operating costs should be in the upper middle section of the global cost curve despite the relatively limited output, Bennerdt said. However, Dannemora is hopeful of getting a concession for a similar deposit at nearby Riddahyttan, which might allow output to be doubled. Meanwhile Bennerdt and his colleagues must wait for confirmation that trial processing was commercially viable.

They’ve been changing the guard at Northland Resources, corporate shakers have regrouped their forces. In essence the company has been further Europeanized, explained Corporate Secretary Deborah Craig. Chairman Anders Hvide has been joined by Karl-Axel Waplan as president and CEO while Waplan was replaced as vice president of Swedish operations by Bert-Ove Johansson who is also managing director of the Swedish subsidiary Northland Resources AB (NRAB). In January 2010 the parent company continued from Vancouver to Luxembourg as Northland Resources SA (NRSA).

Although Northland’s nascent operations are in a former mining area straddling the Sweden-Finland border, unlike the Dannemora and Grängesberg projects they involve completely new mining and processing facility development, potentially on a substantial scale. Johansson explained that, while the key Kaunisvaara Iron Ore Concentrate Project itself has remained essentially the same but more fully permitted through this same period, interest in the project expressed by potential Chinese customers has led NRSA to inject an alternative or additional product transport route into the project feasibility study parameters. The new transportation solution, coupled with new iron ore pricing assumptions, has resulted in an approximately US$7/tonne economic net-back improvement to the project via the use of the port at Narvik.

Costs for shipping to the Asian market are significantly reduced by using the large vessels that can dock at Narvik in Norway rather than the transhipment system necessary at Kemi in Finland. Concentrate would be trucked to the station at either Malmberget or Svappavaara, railed on the line used by LKAB and shipped from a new terminal at Narvik. Johansson said that the Swedish rail authority Trafikverket says this is feasible. Consideration of this option delayed finalization of the Definitive Feasibility Study until the end of September 2010.

Meanwhile, NRSA has reached an offtake agreement for 1 million mt/y for an initial eight-year period with the independent steel trader Stemcor. Now that the DFS has been approved the syndicated banks can seek credit approvals which will then play into one or two more of the company’s potential off-take agreements as the company seeks financing to accompany those off-takes. With an expected boost in the share price, NRSA will look for new equity finance in preparation for construction in the fall.

Grängesberg: Going again?

Like the entrepreneurs who plan to reopen

Dannemora, the Board of Grängesberg

Iron AB (GIAB) saw an opportunity to

enter the iron ore market by reopening the

considerably larger mine at Grängesberg.

By the time of its closure in 1989 this

operation was owned by Swedish Steel

and railed pellets to SSAB’s Oxelösund

works and to other customers from the

adjacent port. GIAB is a subsidiary of

Roslagen Resources, established in 2006,

which has a portfolio of properties in the

Bergslagen district and near Kiruna.

The project is not yet in such an advanced stage as either the Dannemora or Northland Resources ventures, said Executive Director John Thoweman. But completion of an NI 43-101 compliant resource estimate by Behre Dolbear International and the improving market outlook in late 2009 did encourage GIAB to strengthen the board of directors and subsequently to establish a realistic schedule for meeting the company’s target of producing 2.5 million mt/y of high-quality iron ore products.

Thoweman explained that, although the open pit and underground mine had been allowed to flood after closure, GIAB has been able to establish that the three extant headframes and much of the underground ramp, shaft and other infrastructure are intact. The rail terminal and former pellets plant remain in place at the southern end of the mine and some of the adjacent processing facilities are still in use, albeit for different purposes. One of the existing tailings ponds still has considerable capacity and can be refurbished. Consequently, GIAB foresees no insoluble technical problems in mining the 190 million mt of ore averaging 57% Fe estimated to be present from the 400- to 900-m and 1,000- to 1,280-m levels. The orebody is 1.2-km long and 90 m across, dipping south-southeast and may be amenable to block caving. The ore contains about 80% magnetite and 20% hematite but flotation must be used to reduce the phosphorus content.

The rail link to Oxelösund is still in heavy freight use and it should be possible to run trains either to the SSAB works or to a new bottom-dump terminal at the port without much upgrading. Export handling capacity at the port is presently about 1Mmt/y. Some of any transport infrastructure upgrading costs may be met by the Government.

Of course, Thoweman added, drainage of the perhaps 15–20 million m3 of water in the workings will be a major project, with which Sweco is providing technical assistance. GIAB sees possibilities to work with the Grängesberg community to safeguard existing businesses and housing close to the mine—the large Spendrups Brewery was built on the hanging wall—and to develop win-win opportunities.

GIAB is proceeding as carefully as possible, aiming for a production start date in 2014, Thoweman continued. Procurement of consultants for the necessary feasibility studies got underway in first half 2010 and new resource calculations are also in progress. A team from First Securities will prepare for a listing on the Oslo stock exchange and recruitment of key staff will begin. Parts of the project team will eventually move into rejuvenated accommodation in the old mine office building at Grängesberg.

The company hopes to complete the preliminary Environmental Impact Assessment and application for a mining concession this year and to have a Preliminary Economic Assessment and some of the Pre-Feasibility Study data ready for an IPO during 2011. Also next year GIAB will apply for an Environmental Permit, secure the permissions needed for mine dewatering and obtain a 25-year mining concession.

The Full Feasibility Study is scheduled for completion in first quarter 2012, to be followed by a new financing in the second that will pave the way for mine development to start in mid-year when the main levels will be dry. GIAB thinks the Environmental Permit should be granted within the first three months of 2013 and dewatering completed in the second quarter. Production should then be able to start in mid-2014 at the planned rate of 2.5 million mt/y.