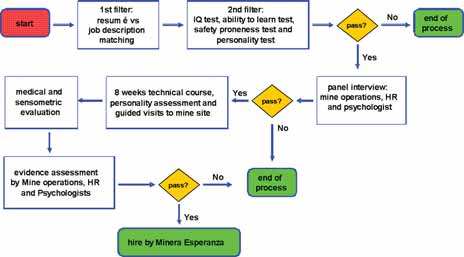

Figure 1-Recruiting process flow sheet.

Haul Truck Operator Training at the Esperanza Mine Project

A three-pronged approach to selection and training provides an 80%-plus success rate

By Rodrigo A. Díaz Bórquez

The training process at Esperanza includes extensive use of simulators and relies heavily on feedback relative to behavior and culture from the instructor to the apprentices. This article describes the results obtained from training 59 apprentices in haul truck operation. The process was 6.5 months long and its success rate was 81%—determined by the fact that 48 students qualified as truck drivers, capable of operating with minimum supervision; five students needed close supervision to operate but were expected to qualify after extended training; and only six students failed to qualify.

Training at Esperanza is based on three main tasks: Knowledge and skills development, behavior development and simulator use.

Prior to the training stage, worker recruiting was conducted using a competency model, illustrated in Figure 1, which included filters, technical instruction and a personality assessment.

The process, which began with CV review and filtering due to the large number of candidates, focused on graduates of Chilean technical high schools located in the same region as the mine, with physical health status compatible with a mining job. Applicants that met these criteria were then given psychological testing to determine learning ability, safety awareness and overall personality.

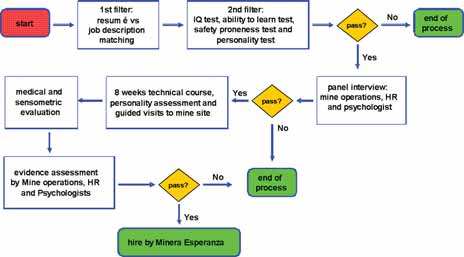

A competency dictionary (Table 1) was used for recruiting. This tool allowed Mine Operations and Human Resources departments to agree on what personal skills to look for in candidates. The process was supported by a psychology professional, which was essential for describing valuebased behavior in such a manner that could be observed in practice with limited subjective judgement. Instructors were specifically trained by an organizational development psychologist in the use of the competency dictionary for behavior evaluation.

Truck Driving Training

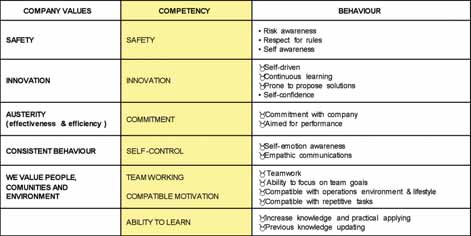

After recruiting, the training in truck operation

is divided in two stages. The first

stage goes from zero to 600 hours of operation and the second goes from 600 up to

2,000 hours. The focus of the first 600

hours is on developing the basic knowledge

and skills to operate ultra class haul trucks

in productive tasks with a required safety

standard. A flow sheet of the training

process is presented in Figure 2.

The discussion in this paper is focused on the first 600 hours of training because in this stage the students learn, from an almost zero starting point, how to operate a truck in productive operations.

Operator training is based on three

tasks. The last two run in parallel:

Knowledge and skill development: Technical

knowledge is acquired using a training

manual. This manual integrates the

OEM technical guide with Esperanza operation

procedures and safety culture. Skills

are developed through supervised practical

experience. Initially, an apprentice will

spend hours in the cab’s spare seat, gradually

moving to the driver’s seat—under

supervision of an experienced operator—

after gaining experience at the simulator

and completing a test drive at the training

course in a real truck. Apprentices will not

operate the truck without supervision until

they complete their simulator assignment

and the instructor assesses their practical

skills with a checklist.

Operation at simulator cabin: At the simulator,

apprentices gain experience using

trucks in productive operations, but in a

virtual world. This provides a chance to

increase operator self-confidence in positioning

the truck at the shovel and when

dumping. Students practice at the simulator

through many sessions during their

training process. To successfully complete

their assignment, students must control

operation emergencies and they must

score zero critical errors.

The emergency control part of the

assignment consists of successfully overcoming

a break failure, an auto-retarder

failure and an engine fire. The second part

of the assignment consists of reducing critical

errors to zero during a given simulator

session. To understand what a critical error

is, it is necessary to explain the simulator

contains a list of warnings stored in the

software that are triggered during the simulation

to alert that truck operation is out

of the normal parameters. Critical errors

are the subset of all errors, which are classified

as ‘critical’ because they can produce

a major accident or breakdown.

Critical errors are written on a list that is

previously known by students.br/>

Behavior development: The instructors

evaluate and provide personal feedback for

all of their students using a behavior development

checklist. This feedback is provided

through interviews that take place in the

middle of the training process and at the

end of it, and is based on 20 specific

behaviors related to safety, learning skills

and teamwork. This strategy gives the students

the opportunity to work on their individual

problems. All instructors were

trained by a professional in order to

improve their feedback skills, enabling

them to base feedback strictly on facts and

observations but also to provide it in an

empathic way.

Completion of the three tasks takes up to six months and when finished, trainees are assumed to be capable of operating a truck in production without direct supervision.

Testing Skills,

Evaluating Progress

All apprentices in the process scored

100% in technical knowledge testing covering

topics that include safety, truck technical

specifications, controls and instruments

and operational procedures. The

testing process is iterative: instructors

focused on items not satisfactorily mastered

in previous iterations until candidates

achieved 100% success. This

process ensured that trainees have sufficient

knowledge of the truck before operating

it—and that they are familiar and comply

with Esperanza’s specific requirements.

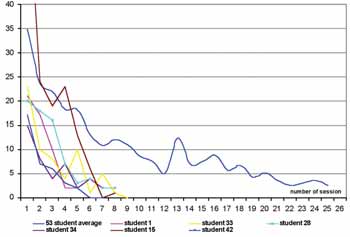

Development of practical skills is achieved through supervised operation (Table 2).

This tool also makes it possible to provide precise and focused feedback to students in relation to their skill gaps.

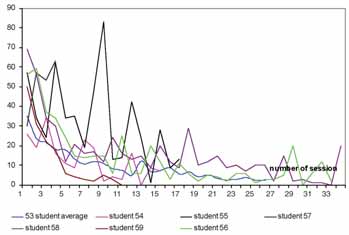

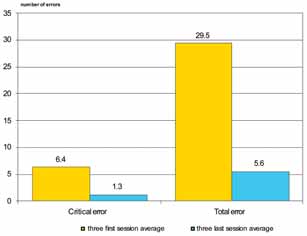

Simulator training decreased the number of total errors from 30 errors per session to six. Critical errors fell from 6.4 to 1.3. It is important to mention that the 1.3 value for critical error in the three last sessions is more a breakdown symptom rather than an error. This was generated when the students experienced an autoretarder failure, which the only way to detect it was through an abnormal increase in the engine RPM.

In Figure 5, the bold line shows the decrease in average total errors per session of all students. In contrast, thin lines represent the results at the simulator of some of the worst performing students. Instead of the fact that in the figure lower performing students showed progress in time, in reality their results at the simulator tended to be more erratic compared to those of their peers.

Assessing Trainee Behavior

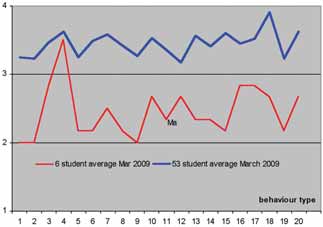

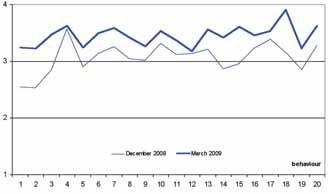

Figure 6 shows the results of the behavior

assessment carried out in December 2008

and its evolution compared to March

2009 (bold line). The X-axis shows the 20

different behaviors evaluated by mine

instructors. The Y-axis shows the frequency

in which the desired behaviors were

observed. Results are presented as the

average score obtained by all the students.

Most of the students, on average, showed

improvement in their behavior and culture

after the instructor provided them standardized

feedback.

These results show that behavior improvement is possible at every segment. In practice, most of the trainees showed improvement after an instructor provided standardized, unbiased feedback.

Behavior and feedback are important components of a company culture. Providing supervision with standardized feedback tools supplies a significant source of evidence for the training process.

Regarding the use of simulators in truck

driver training, we believe this technique

contributes to improving truck driver training

for the following reasons:

• It increases student confidence in a virtual

environment before operating a real truck.

• It allows students to practice and measure

truck operating procedures before

driving a real truck.

• It exposes apprentices to operation emergencies

that cannot be reproduced in a real truck.

• It improves truck operation practices by decreasing

the number of errors in operation.

• It provides a reliable source of evidence

for the labor training process.

Trainees who now operate trucks have achieved an excellent safety and production record, with few significant incidents and productivity of about 80% of the TKPH achieved by experienced operators.

References

Minera Los Pelambres (2008) Manual de

Entrenamiento para Tareas con Camiones

de Extracción Caterpillar 797. Gerencia

Mina, Minera Los Pelambres.