Canada Lithium Corp. has received a

positive, NI 43-101 compliant prefeasibility

study of its Quebec Lithium project

60 km north of Val d’Or, Quebec.

Prepared by BBA Inc. of Montreal in

conjunction with SGS Lakefield, Golder

Associates, Genivar Inc., and Caracle

Creek International Consulting, the

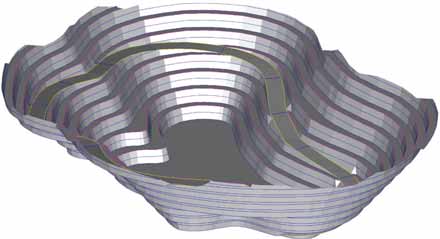

study proposes a Stage 1 open-pit operation

producing 2,950 mt/d of ore and

19,300 mt/y of high-quality Li2CO3 on

site. Total initial capital costs are estimated

at $148 million, including a

$27-million contingency.

“This study is a good indication that

the Quebec Lithium property can compete

financially with most of the lithium

brine prospects under development

but on a much faster timeline,” Canada

Lithium President and CEO Peter

Secker said. “Canada Lithium is positioning

itself to become a significant,

secure North American supplier of

high-quality lithium carbonate within

the next two years.” The company has a

marketing agreement with Mitsui and is

in discussions with North American

lithium buyers based on demonstrated

product quality from bench-scale tests

conducted by SGS Lakefield.

Stage 1 of the Quebec Lithium development

covers a production period of

14.8 years. A definitive feasibility study

scheduled for completion during the first

quarter of 2011 will consider a staged

expansion to higher production levels.

Open-pit mining will be carried out

by a fleet of 10-m3 hydraulic excavators,

front-end loaders, and 100-mt

haul trucks and an ancillary fleet of

dozers, graders, and water trucks. The

stripping ratio will be about 4.26:1.

The proposed processing plant design

is based on conventional crushing,

grinding, and flotation to produce a

6.5% Li2O spodumene concentrate.

Lithium recovery at this stage is expected

to be 82.6%. The flotation circuit is

followed by a secondary pyrometallurgical/

hydrometallurgical treatment process

comprising a rotary conversion kiln,

leaching circuit, a series of precipitation

tanks, washing/filtration circuits, and a

packaging system to produce >99.5%

battery-grade Li2CO3 product. Recoveries

in the secondary stage are

expected to be 82.8%, for an overall

process plant lithium recovery of 68.4%.

During the definitive feasibility

study, Canada Lithium will evaluate

technologies to increase overall lithium

recovery and review the possibility of

converting some of the plant tailings

streams into potentially saleable valueadded

byproducts.

As featured in Womp 2010 Vol 04 - www.womp-int.com