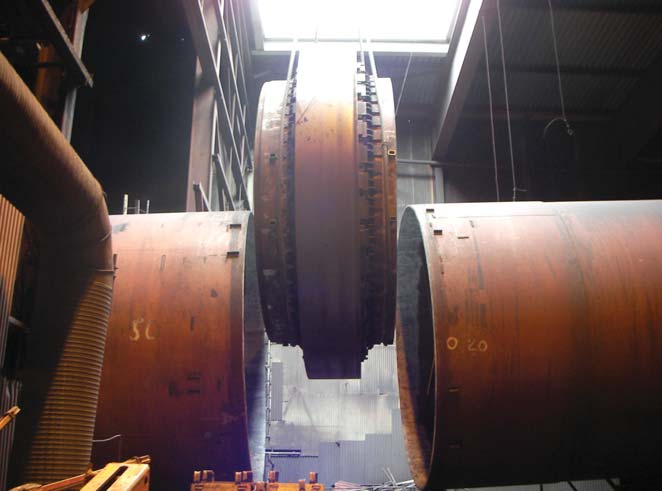

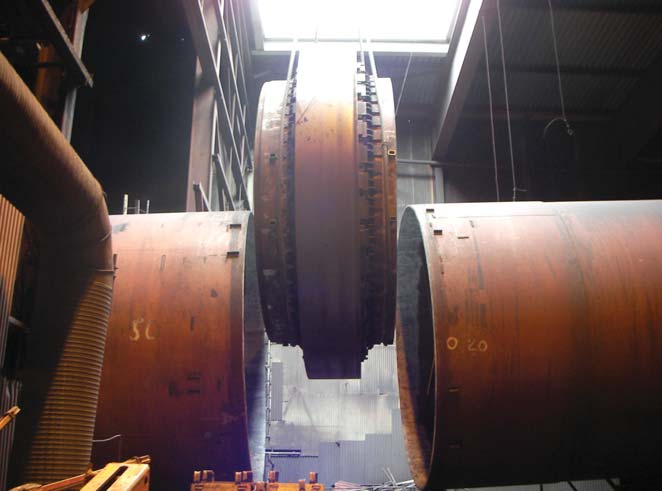

Recent kiln repairs at an LKAB pellet plant in Sweden posed unique challenges to Metso’s engineering and field

teams. The kiln’s old shell section and riding ring—shown here—weighed 178 mt, for example.

Metso Completes Large Kiln Repair Project for LKAB

When LKAB needed to replace a section of kiln shell, riding ring, kiln support rollers and associated bearings on a 20 x 140-ft rotary iron ore pelletizing kiln, they called on Metso to plan and execute the project, having had a four-year working relationship with this supplier.

“This is one of the biggest repair jobs ever carried out at Svappavaara,” said Petrus Esberg, maintenance engineer for LKAB. “The need to replace the kiln shell section has been apparent for several years due to cracks in the shell and stress cracking of the riding ring.” The situation was constantly monitored and a slowdown in the market finally afforded LKAB the opportunity to make the repairs.

According to Metso’s Chris Johnston, supervisor for field service and retrofits, the project required extensive preparation ahead of the installation. “LKAB brought in four cranes for both heavy lifting and precision positioning” he said. “Metso had to coordinate multiple manufacturers and sub-contractors for all the parts and replacement items.”

The sheer size of the kiln and weight of the parts—the old shell section and riding ring weighed 178 mt—presented some unique challenges, but Johnston said that the project provided a great educational, as well as technical opportunity for Metso. “Typically, we would not need more than one field service engineer on site, but this was such an unusual mechanical challenge that we brought in six more engineers so they could learn from the experience,” Johnston said.

“It was really a precision job,” said LKAB’s Bengt Andersson, who had overall responsibility for the project. “There was zero tolerance when the new bearing ring and 5.5-meter-diameter casing was installed. Because of everyone’s commitment to the project we avoided any major disturbances.”

LKAB said it was also pleased with how Metso handled the various sub-contractors. According to Johnston, the co-operative effort between Metso’s offices in Danville, Pennsylvania, USA, and Kiruna was key to the successful completion of the work. “Bengt Hedlin did a great job in the bid process and awarding of contracts,” he said. “With several manufacturers supplying so many different components, there could have been a lot of problems. But we handled it to the complete satisfaction of the customer.”

Coincidentally, LKAB announced in June that it had received several new orders for pellets and fines for delivery during the summer, and subsequently had moved back the date of its planned summer production stop. Under the new schedule, the KK4 pelletizing plant in Kiruna was to operate until July 7 and production of fines (MAF) in Malmberget would continue until July 9. Mining and railway operations were also subject to the change.

Acting President Lars-Eric Aaro said the orders were mainly for deliveries to new customers in Asia, but “we also see a demand in the Middle East, as well as in Europe, where steel producers are starting to replenish their stocks again, although at modest levels.”