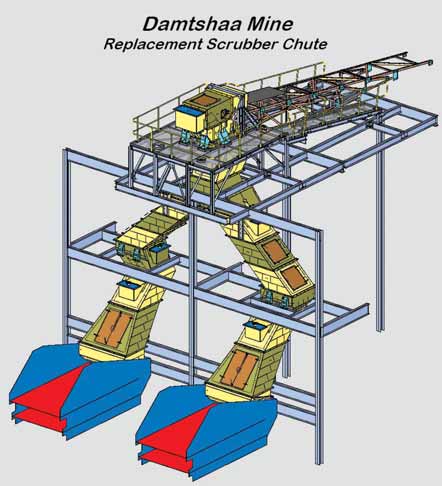

Seven years ago, South Africa-based Weba

Chute Systems designed and installed a

scrubber chute at Debswana’s then-new

fourth diamond mine at Damtshaa in

Botswana. This unit has now been replaced

with a new Weba scrubber chute redesigned

to use the latest technologies and

flow characteristics and to help Damtshaa

attain a throughput of 600 metric tons per

hour (mt/h) rather than the 250- to 300-

mt/h provided by the previous system.

The application, with the scrubbing

process replicated within the chute is very

unusual, said Weba. The chute design

induces directional changes which create

turbulence within the material being transferred.

To further facilitate this replication

of the scrubbing process, water is introduced

at strategic points inside the chute.

The increased capacity of the new chute is

necessary to optimize the scrubbing

process within the chute.

The new scrubber chute is bifurcated

and allows 100:100 operation with a maximum

lump size of 150 mm, as opposed to

a standard operation with 50:50 split. The

chute feeds product directly onto the primary

screen. Specially designed flood

boxes allow for absorption of 1,080 l3/h.

A new head pulley installation was

repositioned to allow the incorporation of

the return fines into the chute in order to

eliminate any fines build up in the dribble

chute that could result in blockage and

excessive maintenance. The support structure

and platforms were built accordingly.

Damtshaa has a projected life of 31

years, during which time the mine is

expected to mine 39 million mt of ore,

yielding 5 million carats. Some 228,000

carats were recovered in 2006.

A Weba chute system has also been

engineered and manufactured for retrofitting

at Debswana’s Letlhakane operation,

the second mine developed by the company,

which opened in 1975. This bifurcating

chute feeds onto two screens and is designed

for maximum lump size of minus

100 to plus 25 mm at a feed rate of 560

mt/h with a peak of 700 mt/h. The incoming

belt is 1,050 mm wide, running at a

speed of 1.63 m/sec. The primary objective

of the redesign and replacement exercise

was to guarantee a 50:50 feed split of

350 mt per leg at all times, onto screen. A

shut-off arrangement was included to close

off one leg when necessary. The chute is

also capable of a 100:100 feed at a maximum

feed rate of 700 mt/h.

An improvement on the previous water

spray system was incorporated in the

design to facilitate an effect similar to that

being achieved with the Damtshaa chute;

and an overbelt magnetic has been fitted

to assist in the removal of any tramp steel

within the ore being discharged into the

chute and onto the screens. Letlhakane

recovered 1,089 million carats in 2006.

Weba says that both these chute installations

have advantages including minimum

maintenance, a reduction in dust

and noise pollution, reduced wear, easy

access for checking, optimum material

flow, a decrease in material degradation

and elimination of uneven belt loading.

These help the mines achieve considerable

savings in manpower and related costs.

As featured in Womp 09 Vol 05 - www.womp-int.com