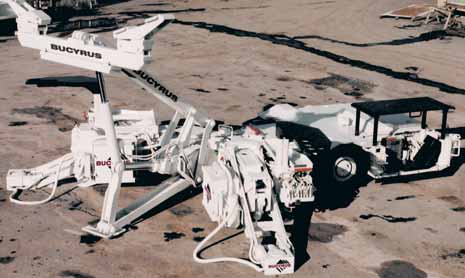

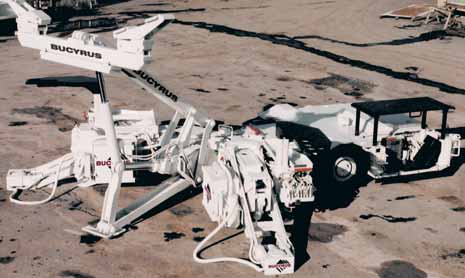

Roof Bolter Product Line Covers a Range of Mining Applications

The LRB-15AR is a rigid-frame, single- arm skid steer machine with ATRS integrated into the boom. It has a 40- hp electric motor with a two-stage gear pump. When equipped with 26-in. tires, it provides 6 in. of ground clearance, 32 in. of tramming height and a 76-in. ATRS reach. It complies with MSHA ATRS load certification with a capacity of 11,250 lb, and features a 50-in. drill boom feed and 7,000 lb of drill feed thrust.

The RB2-52A meets MSHA ATRS load certification requirements, and features a 52-in. drill boom feed and 10,000 lb of drill feed thrust. When equipped with 32-in. tires, it provides 8 in. of ground clearance, 37 in. of tramming height and a 96-in. ATRS reach. The RB2-88A, when equipped with 35-in. tires, provides the most ground clearance of the Bucyrus roof bolters, giving a total of 9.5 in. of clearance, 48 in. of tramming height and a 120-in. ATRS reach. ATRS load certification is 33,750 lb. This model has an 88-in. drill boom feed and 10,000 lb of drill feed thrust.