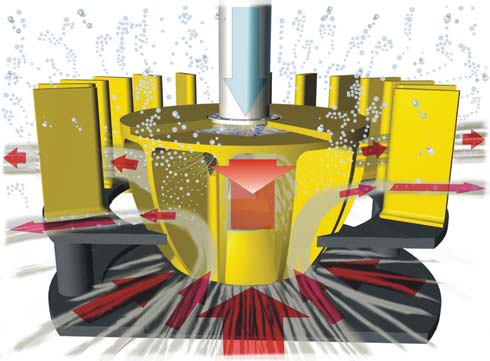

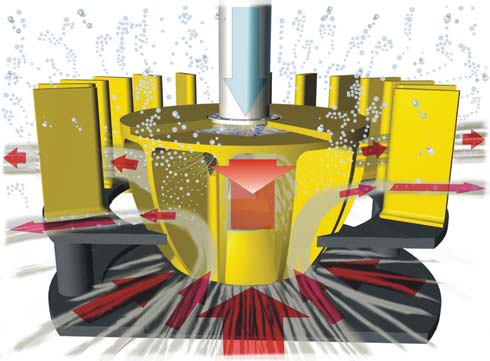

Diagram of optimized airflow of FloatForce, a mixing mechanism installed in new operations and retrofits,

and offering power savings of up to 20%.

Managing the Downturn: Now is the Time for Excellence in Operations

By Andrew Okely

Nowadays, with all of the current market uncertainties and talk of doom and gloom, some operators will be battening down the hatches, cutting costs wherever they can and waiting for the financial hurricane to subside. And now, more than ever, is time to start checking, controlling and analyzing the full supply chain, both up- and down-stream, thereby optimizing productivity and minimizing unnecessary costs. To do this effectively and efficiently, some investments may need to be made. If this is done properly, the savings generated will far outweigh the initial outlay. As always, in good times and bad, throughput is king, but it is now particularly important to look at the impact of process efficiencies on the bottom line. So, this article will review some of the techniques used to keep tons up, while minimizing investments.

Apart from improving wear life, some OEMs also strive for efficiencies in components such as power consumption savings or metallurgical recovery improvements. Examples that come to mind are flotation cell mechanisms, grinding mill liners, screens, pump liners and the like. With FloatForce, for example, Outotec’s new flotation mixing mechanism, it is designed for better wear life and easier maintenance. It also offers potential power savings up to 20% and optimized metallurgical performance.

In many cases, upgrading to the latest design when wear items are changed out can provide improvements in operating costs far beyond the cost of the component. It is good business sense to always ask an OEM about technology improvements before replacing wear items.

Review Concentrator Set-Up for Current

Ore Type and Throughput

In many cases, such a sudden change in commodity prices

will lead to a change in mining strategy. Perhaps fewer tons at

the same grade or at a higher grade, or even more tons at the

same grade may be appropriate. Such changes are driven by

mine economics but what about the concentrator?

In most cases any significant change in throughput or

grade will require modification of the plant set-up. Some

areas to examine include:

• Crusher setting if throughput or ore type changes.

• Target p80 if grades change.

• Grinding ball size if throughput changes.

• Number of flotation cleaner stages with feed grade amends.

• Froth crowder modifications in flotation cells at lower

tons and/or grade.

• Size of flotation cell slurry control valves.

• Modified thickener feed rates may require optimization of

thickener settings.

• Are all the pumps still suitable?

In many cases, the best people to advise on changes to technology set-up are the original designers. If the mill faces a significant change in plant throughput or ore grade, then it is always prudent to generate a new mass balance and compare it to the original design criteria. There is nothing worse then changing a mining strategy to survive in a downturn, only to see the concentrator efficiency lose the planned gains when a few relatively inexpensive changes could have made all the difference.

Training, is it Up to Date?

With far less staff turnover than during the boom, and job

cuts on the horizon, a reduced workforce needs to be operating

at its best. Now is the best time to ensure that operators

and maintenance staff are well trained on the technology

used in the concentrator. The effectiveness of the staff is

never more apparent than in tight times, when it is particularly

essential to have a competent and skilled workforce.

Correctly operating a plant will improve throughput and

recovery and minimize maintenance. Many OEMs offer training

programs, with content targeted specifically to a particular

site’s technologies and needs—either on-site or off.

Spare Parts Management

During boom times many operations suffered from high staff

turnover. One of the many downsides is the potential for confusion

in the spare parts area. In a downturn it is important

to know exactly what parts are on site, what they are for, and

where to source replacements in a timely manner. It is never

desirable to be airfreighting parts for a shutdown, but this is

particularly so when margins are thin. Equally, it is important

to know what parts are imported and impacted by currency

fluctuations. An OEM spares manager is a good source of

support in managing these issues. In many cases, they may

have better records of items such as part numbers, how often

parts need to be replaced and their lead times. So, now is the

time to ensure your spare parts list is up-to-date.

Talk to Technology Partners

Tap into the expertise and knowledge of those whose core

competencies are key deliverables on site. After all, these are

the very people who should have best practices and advice on

how to, say, audit and optimize the operation of the thickening

circuit or manage construction planning, on-site management

or even installation and commissioning. This leaves a

(probably reduced) workforce to the job in hand. The needs

could even be something as simple as questioning how to

protect the integrity of the bubbles in the flotation cell in a

high wind area (the answer could be a simple and inexpensive

one; i.e. install a wind guard). Some may question the

use of external companies in times like these, but, avoid

panic by knowing whom to contact. This is time and money

which could not be better spent.

Don’t Panic

Which brings us to the last point. Sudden changes can lead

to decisions being made in a hurry without necessarily consulting

all sources of available information. It is important to

remember that the fabric of the industry and its proven

record of innovation has not disappeared simply because

commodity prices have fallen. Talk to the workforce, industry

contacts, suppliers, technology partners—look for ideas on

efficiency improvements in the operations together.

Andrew Okely is manager–minerals processing technologies for

Outotec Pty Ltd. in Australasia.