Nippon Piloting New Copper-Gold Extraction Process

The N-Chlo pilot plant is budgeted at a construction cost of $27 million and operating costs of $7 million. Production capacity will be 100 mt/y of copper. Construction is scheduled for completion in March 2009, and the test program is scheduled for completion in March 2010.

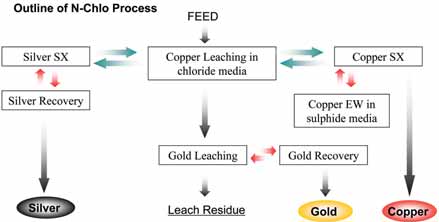

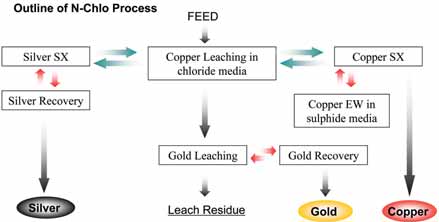

The N-Chlo Process is based on chloride leaching and solvent extraction technology in use across Nippon’s wide range of nonferrous metal processing operations, including copper slime processing and hydrometallurgical nickel-cobalt recovery from mixed sulphides. The three primary processing steps are hydrometallurgical leaching, copper/gold solvent extraction, and copper electrowinning. The characteristic feature of the process is that it enables effective recovery of copper as well as precious metals from low-grade copper concentrates.

In announcing the pilot plant, a Nippon statement said, “Today, development of mines that would produce low copper grade concentrates is difficult, even if the concentrates contain precious metals, because pyrometallurgical processing is not suitable for such concentrates due to the low copper grade and rich impurities and because existing hydrometallurgical processing cannot achieve effective recovery of the precious metals. The N-Chlo Process is suitable for the treatment of such concentrates and would enable development of mines that would produce such concentrates. In addition, in concentrates from existing copper mines, the copper grade is getting lower and impurities are getting higher, because higher-grade, clean orebodies are being exhausted. The N-Chlo Process is a technology that can prolong the lives of such mines.”

If the N-Chlo pilot testing is successful, Nippon expects to acquire interests in and participate in the development of mines where the process is applicable.