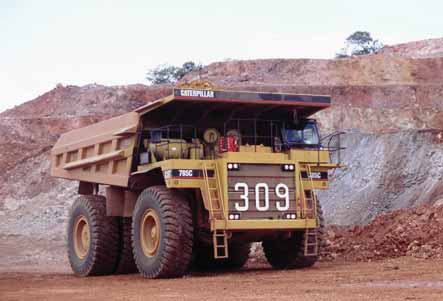

Fifteen Caterpillar 785C trucks (left) and 12 Cat 777D trucks (right) work to haul both waste and ore.

Los Filos Gold Project Sets Mining Standard in Mexico

Goldcorp’s newest mine is moving in the direction of world-class status, and is likely

to be around for a long time

By Mark W. Sprouls

Adjacent to the Nukay mining and milling operations of the Goldcorp Luismin division, Los Filos has grown up under the watchful eyes of Luismin veterans. “Being here from day one and participating in the design, construction and operation of one of the largest mines in Mexico is very fulfilling professionally,” says Tomás Iturriaga Hidalgo, general manager of Los Filos. “I feel that we have put together the best team in Mexico for open-pit mining and heap leaching. I’m very proud of being part of this team.”

“Considering that Bermejal is much bigger, incorporating it into the original plan was challenging,” Iturriaga says. “Though an equally critical aspect was people—gaining community support for a large mine and finding and hiring qualified personnel.

“We developed a successful training program by working with Madisa (the regional Caterpillar dealer), and we were able to bring in local people to be trained as operators through both classroom and on-the-job training during development of the mine,” Iturriaga says. “There are underground mines in the area, so local residents are familiar with mining and machinery. The supervisors were recruited from all over Mexico, however.”

Also, the Los Filos managers nearly eliminated the need to find qualified service technicians by developing a maintenance and repair contract (MARC) with Madisa. Madisa’s on-site staff of about 80 people handles all preventive maintenance and repairs of the mobile equipment fleet as well as logistics for parts supply. The arrangement with Madisa also enables the mine to pin down maintenance costs for planning purposes.

The result of planning, permitting, hiring people and acquiring a fleet of new equipment is a two-pit operation with about 500 people, including contractors, working at the mine and using about 50 pieces of major mining equipment. The peak total material mining rate is 66 million tons annually.

Bermejal, the larger of the two pits, moves about 100,000 tons of material per day. All of the gold-bearing material from Bermejal is destined for run-ofmine leach pads. The stripping ratio in Bermejal is about 1.4:1, and the ore grade is about 0.6 grams per ton of gold. The Los Filos pit yields an overall higher grade of about 1 gram per ton of gold, but the stripping ratio is a more demanding 2:1. The pit sees about 70,000 tons removed daily. The higher grade material, about 45% of the total mined in the Los Filos pit, goes to a crusher and agglomerator before being conveyor stacked and heap leached. Lower grade ore is hauled directly to the run-of-mine leach pad. The mine plan calls for the project to handle an average of 24 million tons of ore annually.

The recovered solution is treated to produce a final gold doré product on site. Gold and silver recovery will take place in a carbon adsorption-desorption-recovery plant using four trains of five cascade columns each. Commercial production commenced January 1, 2008, and the mine is expected to produce an average of 300,000 oz of gold annually. Proven and probable reserves now total 4.51 million oz, but that is likely to increase as drilling and reserve analysis continues.

Fifteen Caterpillar 785C mining trucks with 136-mt target payload work with five Hitachi EX2500 hydraulic shovels. Twelve Caterpillar 777 trucks— 11 are D models and one is an F model—have 90-mt target payload and work primarily with three Cat 992G High Lift wheel loaders. The 777s also work with the shovels as needed.

“The wheel loaders offer great mobility and flexibility,” Iturriaga says. “That mobility allows us to use wheel loaders in smaller mining areas, because a wheel loader can move to the next face quickly. Shovels require much longer-life mining areas.”

Waste material benches are 12 m in height, and ore benches are 6 m high. The wheel loaders work primarily in ore loading.

The mining fleet includes seven blasthole drills, several Caterpillar dozers used for building roads and aiding production, a single Cat 824H rubbertired dozer that works on shovel benches, and a trio of Caterpillar motor graders—two 16Hs and one 14H—for maintaining haul roads.

Due to the truck tire shortage throughout the mining industry, Los Filos has emphasized good road construction and maintenance. For long life roads, aggregate road base was brought in for road construction. Throughout working shifts, the motor graders are dispatched quickly via radio to clean up any rocks on roads.

Los Filos also has the Caterpillar Road Analysis Control (RAC) system on its 785C trucks to help determine when and where road maintenance is needed. The system monitors strut pressures to determine truck frame rack, pitch and bias. Integrated with the Vital Information Management System (VIMS) on each truck, RAC provides real time feedback about haul road conditions that are detrimental to cycle times and power train, frame, suspension components and tires. The data is recorded on the VIMS data system on each truck and can be transmitted in near realtime via radio to a supervisor.

The maintenance crews work out of a large, fully equipped nine-bay shop. A separate preventive maintenance building is plumbed with bulk lubricant lines for fast fluids service. That building is placed near the outdoor wash facility which features state-of-the-art equipment for cleaning and recovering wash water. An additional building houses the welding shop, which helps keep the other maintenance buildings clean.

Los Filos subscribes to a comprehensive contamination control program to keep dirt and water out of oils and fuel. Caterpillar studies have shown that keeping fluids clean extends component life and reduces downtime. As examples of the program, bulk tanks are all fitted with appropriate breathers that filter and dry air, and fluids are filtered as they are pumped out of the tanks. The maintenance crew assesses fluids by using a particle counter to check for the presence of contaminants in storage systems and in machines.

The efforts of the Los Filos and Madisa team are bringing success. With the oldest trucks now accumulating 10,000 hours of operating time, the Cat machines continue to deliver high availability and are exceeding the MARC requirements.

Looking Forward

The Los Filos operations are growing

toward world class status, and they are likely

to be around for a long time. Exploration

drilling is continuing on pit extensions

especially in higher grade ore areas.

According to Goldcorp, the work has “…returned encouraging drill intersections that can be economically serviced from underground and possibly open-pit. The strategic aim of the project is to continue developing further ore volume and higher grade ore from Los Filos, El Bermejal and the neighboring Nukay district that will justify a new conventional milling operation in parallel with the heap leaching operation.”

Mark W. Sprouls is a freelance writer based in Tucson, Arizona, specializing in coverage of the mining, construction and demolition industries.