Magnetic Separation System Enhances Nepheline Syenite Production

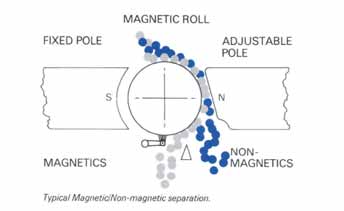

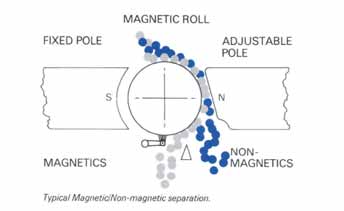

Nepheline syenite is a feldspar-like mineral with similar applications in the ceramics industry, where it is used as a flux in the production of tiles, sanitary ware and porcelain. It has certain properties which make it superior to feldspar, primarily the “whiteness” it produces in these products which can be highly valuable in the marketing of high quality sanitary ware, for example. An important part of preparing it for industrial use is the removal of ferrous contaminants which may be weakly magnetic or paramagnetic, and which require the use of powerful magnets to achieve the purity required.

Deposits of nepheline syenite are found in various parts of the world, with major occurrences in North America and parts of Europe. Sample testing showed that a deposit in Iran would be commercially exploitable, so an initial production plant was commissioned. This utilized permanent magnetic separators for purification purposes, but it was found that in practice too much contamination was left in the product. Further tests were carried out using the Master Magnets Induced Roll machine which gave demonstrably better results.

Various machine configurations are available; to meet the requirements of their Iranian customer the company proposed a four-roll machine, with each roll 1,000 mm long. The rolls are arranged in pairs so that the total flow was split between two rolls in parallel, each of these having a secondary roll to retreat the product. Using this layout, a high degree of cleanliness was possible at a production rate of 8 mt/h. Other configurations are available using 1, 2, or 4 rolls, with roll lengths from 500 mm to 1,000 mm.

Test work was carried out on a labscale version of the Induced Roll, which is identical in all respects to production machines other than its roll measures only 125 mm long. Results obtained on this machine can therefore be directly scaled up. Test work of this nature is routinely carried out in the laboratory at Master Magnets to confirm equipment selection.

According to Master Magnets, the four-roll separator is now operating satisfactorily at the customer’s processing plant, producing clean nepheline syenite free of magnetic impurities.