Nevsun, Eritrea Reach Development Agreement on Bisha Project

According to Nevsun’s press statement, in October the government of Eritrea indicated strong support for the Bisha project and for the development of a mining sector in Eritrea by acquiring a 30% paid participating interest through the Eritrean National Mining Co. (ENAMCO). The shareholder structure of BSMC is 60% Nevsun and 40% ENAMCO, with the ENAMCO shareholding comprising a 30% paid participating interest and a 10% free participating interest as provided by the country's mining legislation.

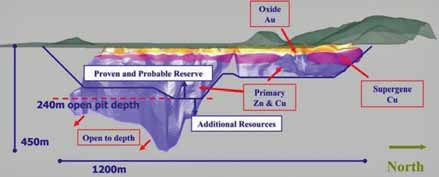

The Bisha deposit is configured in three layered zones (see below): a 35-m-thick surface oxide zone having a high gold and silver content immediately overlying a 30- m-thick copper enriched supergene zone which itself overlies a primary sulphide zone containing both zinc and copper. According to the project’s feasibility study, Significant byproduct gold and silver are recoverable from both the supergene and primary ores.

The fully diluted proven and probable

reserves mined by open-pit methods for

each ore type are as follows:

According to the project’s 43-101

Technical Report published by Amec in

November 2006, conventional open-pit

mining methods will be used, utilizing

heavy-duty highway trucks loaded by excavator/

loader. The milling rate will be 5,500

mt/d ore over an approximate 10-year mine

life. Mining will be performed by the owner

with purchased equipment. Waste stripping

will vary by year, starting at 20,000

mt/d in year 1 to a maximum of 40,000

mt/d in year 7, and subsequently decreasing

to 4,000 mt/d in year 10. The average

waste stripping rate is 23,000 mt/d.

Processing of the three ore types will employ a common crushing and SAG/ball grinding circuit, but will require three different extraction and processing circuits. After grinding, gold and silver will be extracted from the oxide ore by conventional cyanide leaching and recovered by the carbon in pulp process. Later in the project the supergene and primary ores will be processed by conventional flotation to recover copper and zinc as concentrates for direct sale to smelters. The tailing systems will be common for all three ore types. Capital costs to develop the Bisha mine were estimated at $196 million as of October 2006.

In the first two years of production, gold and silver will be extracted together. Production of copper concentrate will begin with a minor amount in year 2, significant quantities for years 3 to 5, and smaller quantities in years 6 to 10. Zinc concentrate production occurs only in years 6 to 10.

According to the technical report, major infrastructure required to develop the property includes a power generation facility and a well farm for freshwater supply. The power generation system will consist of multiple containerized, diesel engine-driven generation units, which will be owned, operated and maintained by a third party supplier. Freshwater will be supplied from groundwater. A well farm has been proposed 6.5 km southeast of the process plant site, along the base of the slope of the adjacent mountain range. Facilities for concentrate storage and loadout will be located at the site of an existing cement production facility at the port of Massawa. The plant, adjacent to an existing jetty, is owned by the Eritrean government and will reportedly be made available by the government for use by Nevsun.