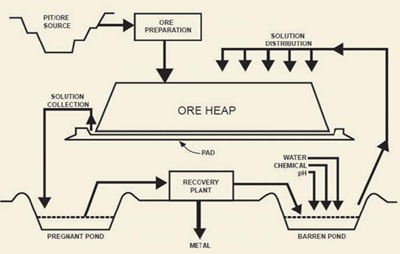

Schematic of typical heap leach process. Source: Van Zyle, D. J.A., et al. “Introduction to Evaluation,

Design and Operation of Precious Metal Heap Leaching Projects,” pp. 122-145, (1988).

Technical Factors for Selecting Optimum Heap Leach Pad Sites

Selection of a pad site can have significant, long-lasting effects on leaching

performance, safety and environmental impact

By Saeed Karimi Nasab, Azadeh Hojat and Mohammad Reza Mollaei Fard

Selection of a site for a heap leach pad may be undertaken using procedures used for tailings impoundment site selection. One of the early, but still relevant and applicable papers available on site selection is by Robertson et al.1 A similar but expanded approach is described in Caldwell and Robertson.2 In essence, the basic approach described in these two papers involves identifying candidate sites, comparing alternatives, communicating the subjective and objective criteria affecting the choice of site, and validating the site selected. Modern decision making theory as applied to site selection is described by Robertson and Shaw.3

Because conditions often vary significantly between sites—even those in close proximity—careful selection of the site having the most favorable set of advantages is a major design option. The selection process may involve many technical disciplines and can include both non-technical issues such as property availability, as well as technical criteria that include topography, geology, hydrology, environmental and engineering conditions.

Site selection involves evaluations of a number of factors, including distance from the mining area and dumped ore, environmental suitability, and the amount of earthwork that must be done to provide grading of the slope for proper drainage of the heap. Additional factors to be considered in site selection are: flood potential, subsoil conditions, and future prospecting potential for economic mineralization. Thorough testing of soil and rock beneath the proposed heap leach site is necessary to ensure stability of heaps.

Site Investigation Methodology

A desk study is usually conducted which

almost invariably involves the review of

topography, geological and vegetation

maps, as well as geological, climatological

and site investigation reports. This is

followed by site reconnaissance visits,

which can help to validate information

obtained during the desk study.

Fieldwork generally provides key technical

data such as:

• The sequence of soil and rock strata

with depth.

• Depth to bedrock.

• The distribution of soil and rock over

the study area.

• Discontinuity intensities of rock at the

site.

• Prediction of bedrock topography.

• Groundwater distribution and seasonal

variation.

• General direction of groundwater flow

and consequent contaminant threat of

leachate to groundwater resources.

• Aquifer properties.

Site Selection

Mining companies face the challenge of

effectively managing heap leaching facilities

through a life cycle, from site selection

to final closure. The first step in the

selection of sites for heap leach pads,

collection ponds, and the extraction

plant is the delineation of an area of

interest where sites can be defined and

selected. Because sites located far from

the mine may be uneconomic, a fixed

radius from the mine will typically define the area of interest. The length

of the

radius is a practical distance from the

mine dictated by hauling costs and other

operational factors. For heap leaching

facilities, the area of interest is within a

one-half to 1-mile radius.

Within the area of interest, there may be areas where facilities should not be sited for reasons that include ownership, topography, potential flood areas, subsoil conditions, and mineralization. The remaining sites are then screened to eliminate areas that are less suitable; i.e, steep topography, unfavorable geologic conditions, unacceptable hydrologic conditions such as high runoff (which can not be diverted easily), risk of failure, environmental considerations, etc. The remaining candidates are then compared to determine the best (or sometimes the least unacceptable) site.

The site selection process is generally an extension of good judgement and common sense. For some projects, only one site may be available or one may be substantially better than all others, and the process is not required. For other projects, several good sites may be available but the optimum site among them is not readily apparent. In such a case, the site selection process is used to determine which site would be preferable. Costs involved in the site selection process may be offset by future engineering, construction or operational cost savings.

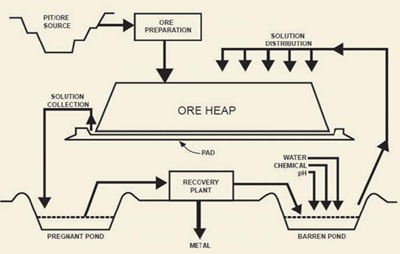

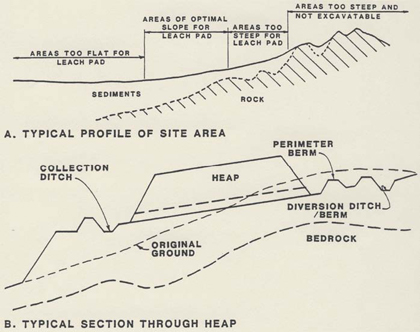

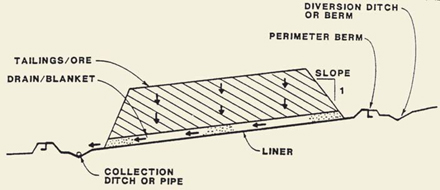

The slope of the pad and associated liners is very often controlled by the existing topography. The slope of the pad must be steep enough to allow efficient drainage of the leachate but not so steep that the stability of the heap is jeopardized or that erosion of the liner occurs. In many cases, it is possible to construct a leach pad using the existing topography without significant cut and fill.

Meteorological Conditions

Characterization of the meteorological

conditions of a heap leach site includes

collecting historic data about site precipitation,

evaporation, snow, humidity, temperatures,

and wind. Interaction of climate

and the design and performance of

mine waste management facilities is

described by Hutchinson and Ellison.4

Specifically with regard to heap leach

pads, they consider the following climatic

factors and their significance:

• Short-term–intense rainfall affects the

size of ponds, ditches, and containment

dikes that need to be designed to

avoid erosion and/or overtopping.

• Long-term–weather patterns affect the

overall water-balance performance of

the pad as regards infiltration, evaporation,

and hence the quantity of flow

from the pad.

It is also necessary to evaluate wind direction and velocity in the potential sites. Wind direction and velocity are critical because of dust problems that can be caused by erosion, especially in sites up-gradient from towns, recreation areas, farm lands, etc. Persistent high-velocity winds can also complicate reclamation of abandoned heaps. An example of the use of climatic data in the design and performance evaluation of heap leach pads and similar mine waste disposal facilities is provided in Wels et al.5

Hydrology

Hydrologic studies consist primarily of

the acquisition of data on precipitation

and runoff. Runoff estimates indicate

the rate at which non-process water can

be expected to enter the site. Diversion

systems (ditches, berms, etc.) should be

designed to handle extraneous water.

Precipitation can affect leaching operation

in several ways. It reduces pH and

density of the solutions. Collection

ponds should be designed larger to store

leaching solutions as well as rainwater

collected from the heap and channels.

The pregnant solution pond must be

designed to receive runoff from a 100-

year maximum flood occurring in the

total heap area being drained. This pond

must handle runoff from the annual

spring snowmelt. Sometimes, it is necessary

to cover the heap surface with

impermeable materials to prevent rainwater

from percolating through the heap.

Geology

The geology of a heap leach pad should

be established comprehensively. This

may be done during geological studies

usually undertaken as part of the overall

mine investigation, characterization, and

development. Geological data about the

origin, location, and engineering characteristic

of site and local soils, rocks, and

groundwater should be obtained.6

Hydrogeology

The interaction of site groundwater and a heap leach pad is discussed

by Hutchinson and Ellison.4 In theory there is no interaction

of the heap leach pad and groundwater because the liner

placed at the base of the pad precludes passage of groundwater

up into the heap and passage of seepage from the heap to

groundwater. In practice, the following considerations give rise

to a need to integrate heap leach pad design and operation with

groundwater evaluations:

• Springs and/or artesian groundwater flow at the heap leach pad

site may necessitate placement of drains beneath the liner,

• Holes in the liner may result in the passage of leachate to the

groundwater,

• Water pressure beneath the pad may affect slope stability.

Therefore, the site selection process for the proposed facility

should include consideration of subsurface hydrogeological

conditions within and adjacent to the potential zone of influence

of the proposed site. A risk assessment of potential

impacts on groundwater chemistry, levels and appropriate

groundwater pressure should be conducted as a minimum. It is

essential to determine groundwater flow system in the vicinity

of the site from which escaping solutions may be released to

underground aquifers. The most appropriate rules for site selection

according to hydrogeological characteristics are:

• Select the site underlain by the maximum possible thickness

of unsaturated materials.

• Select the site underlain by materials with lowest possible

permeability.

• Select the site not underlain by shallow aquifers without confining

layers.

• Avoid sites that are adjacent to streams where groundwater

and the contaminated seepage it collects will discharge

immediately to the stream.

• Provide seepage collection facilities where seepage is

anticipated.

• No heap leach facility shall be constructed on reclaimed or

filled land.

Geotechnical Studies

The general geologic and geotechnical characteristics of potential

areas should be among the first factors to be examined.

Depth to and topography of buried bedrock should be determined

for structural and drainage purposes. Unconsolidated

materials should be mapped and their grain-size distribution,

permeability, and engineering properties determined so

that potential settlement, leakage, and other failure problems

can be anticipated and incorporated into the design of facilities.

In general, a geotechnical site investigation for a heap leaching

project is conducted to gather the following information:

• Foundation conditions beneath the heap, ponds, and other

areas where additional load is added to change the stress conditions

in existing rock and subsoil.

• Excavation conditions, or how easily materials can be excavated

in areas where cuts are required.

• Quality and quantity of potential construction materials available

for liners, drainage material, and structural fill.

• Hazards associated with the site such as recent or active

faulting, unacceptable groundwater conditions, or soft or

collapsible soils.

• General identification of geologic and

hydrogeologic conditions beneath

structures such as the heap pad and

collection ponds.

Techniques used to gather this information vary from surface reconnaissance to backhoe trenching and drilling.

One important consideration associated with such facilities is differential settlement. Settlement of the underlying foundation may lead to disruption of the leach pad system. Differential settlement typically results from one of three causes: the liner spans soils of differing compressibility, the slope and height of the heap are extreme or local settlement results from leaks in the liner. The later cause can be significant where the soils contain high concentrations of acid soluble salt.7

The geotechnical risk assessment may also include a seismic assessment of the site as well as an assessment of the liquefaction potential of foundation, construction and stored materials. The investigation(s) should provide a high level of confidence in the physicochemical characteristics, the engineering and hydrogeological properties, and the behavior of the foundation, construction and stored materials under normal operating and seismic loading conditions.

Leach pads—particular those involved in copper ore leaching—can be enormous, reaching areas in excess of 5 million m2. This often precludes selecting of the optimum site from a geotechnical standpoint. It also requires a liner system to span a wide range of geologic profiles.

Exploratory procedures for construction materials involve pitting, trenching, and drilling. The exploration program should identify alternative sites as to quantities of the various classes of construction materials available. The materials at the alternative sites should be classed according to volume available, water content, grain-size distribution, compaction characteristics and shear strengths.

The characteristics of natural materials vary from site to site, and even within parts of a particular area. Because of the variability of these materials, and their potential use as an important component of the leach facility, their geotechnical characteristics (as well as their quantity) should be determined.

Environmental Considerations

Although heap leaching facilities have

leak detection systems and often use

double liners, most facilities employ

leak detection or monitoring systems so

that leaks can be discovered and remediated.

However, there is always the

possibility that detection will fail and

leakage will escape to the underlying

strata.

In general, heap leach facilities can

cause the following major types of environmental

impacts:

• Solution containing ponds and ditches

can present an acute hazard to wildlife

and birds.

• Spills of leaching solutions can enter

surface water and contaminate drinking

water sources; or they can enter

groundwater systems and contaminate

water supply wells.

• Chemical solutions in the active heaps

and solution ponds may reach water

sources through leaks from leach pads

and liners.

• Catastrophic failure of heap leach pads

can release chemicals into streams and

groundwater.

Such problems associated with chemical solutions in heaps have led operators to explore preventive strategies. These include reviewing environmental parameters in the initial site selection. The proper location of heap leaching facilities can be the most simple and the most effective factor in enhancing the successful long-term protection of groundwater quality. Proper site selection also represents the most powerful tool available to the engineers in ensuring the long-term stability of a heap leach pad.

Preparing an environmental assessment requires a number of environmental studies in the region of the proposed site. These studies generally address geology, hydrology, soils, vegetation, wildlife, aquatic features, history and archaeological aspects of the area.

Heap leaching ponds may also attract animals and birds for water. Consequently, preventing bird poisoning on wet heaps and ponds, especially in desert climates where the ponds are attractive sources of water, is a concern.

However, the major environmental concern with heap leaching is contamination of surface and ground waters with chemicals in the leaching solutions. The closure of heaps which have ceased to be productive requires taking account of additional environmental considerations

Mineralization

Leached ore is typically left in place,

which means that a site should be located

where no economic mineralization lies

under the permanent disposal of the

leached ore residue. Some exploration

drilling may be appropriate to ensure that

the selected site does not overlay economic

mineralization.

Distance from Mining Area

Leach pad foundations are designed for

high stability to prevent movement or

cracking of the pad liner under the

weight of the ore heaps, which may reach

heights of 60 to 70 m or more. However,

heap movement may occur with high

heaps or heaps located on steeply sloping

sites. This problem should be considered

in the site selection process in order to

select sites safely removed from the mining

area.

Conclusions

Experience across the mining industry

has consistently demonstrated that the

most significant catastrophic risk posed

by mining operations on the environment

arises from the construction and

operation of tailings, heap leach pads

and water storage facilities. Because of

the long-term nature of the pollution

and environmental impact of many such

facilities, the selected site must serve

as an effective area, not only in the

short term, but also in the very long

term. The proper location of heap leaching

facilities can be the most simple

and the most effective factor in enhancing

successful long-term efficiency of

the facility.

The authors wish to thank National Iranian Copper Industries Co. for supporting this research.

References

1. Robertson, A. et al. “Uranium Mill

Tailings Impoundment Site Selection,”

Symposium on Uranium Mill

Tailings Management, Fort Collins,

Colorado, (1980).

2. Caldwell, J.A., and Robertson, A.,

“Selection of Tailings Impoundment

Sites,” The Civil Engineer in South

Africa, (1983).

3. Caldwell, J. “Technology Review;

Heap Leach Pads,” Infomine, (2006).

4. Hutchinson, I. P.G., and Ellison, R.

D., “Mine Waste Management,” Lewis

Publishers, pp. 453- 497, (1992).

5. Wels, C., et al. “Infiltration Test Plot

study for Mine Rock Piles at Questa

Mine, New Mexico.” 2001 National

Meeting of the American Society for

surface Mining and Reclamation,

Albuquerque, NM, (2001).

6. Miguas, R.E. “Geology and Engineering

Geology in the Siting of Complex

Public Facilities,” Geotechnical Site

Characterization, (1998).

7. http://www.geomembrane.com/PGI

Saeed Karimi Nasab is assistant professor,

Mining Engineering Department,

Shahid Bahonar University of Kerman, Email:

kariminasab@mail.uk.ac.ir. Azadeh

Hojat is a Ph.D. student of geophysics,

Institute of Geophysics, University of

Tehran, Tehran, Iran, E-mail:

ahojat@ut.ac.ir. Mohammad Reza Mollaei

Fard is a mining engineer, National

Iranian Copper Industries Co. E-mail:

mollaeifard@nicico.org.

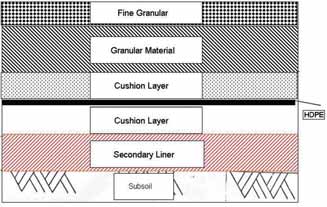

The Sarcheshmeh copper mine is located 160 km south west of Kerman and 50 km south of Rafsanjan in Iran. Its copper deposits are situated in the central Zagros mountain range, principally composed of a folded and faulted early tertiary volcano- sedimentary complex. The copper complex includes the mine, concentrator, smelter, refinery, casting and leaching units. Heap Leaching at Sarcheshmeh Heap leaching has been used to extract copper from oxide ore at the Sarcheshmeh copper mine in southern Iran since the 1990s. The total amount of oxide ore available at the mine is approximately 28 million mt. Sarcheshmeh is the only mine in Iran utilizing heap leaching technology. After technical studies of various leaching methods revealed that heap leaching was the only viable method to extract copper from oxide ore at Sarcheshmeh, the National Iranian Copper Industries Co. (NICICO) decided to construct two heaps in the northeastern and northwestern sides of the mine, respectively. Heap No. 2 was commissioned in 2001 after Heap No. 1 had been in service for several years. Heap No. 1 is now in its last year of operation. Of all the alternative sites evaluated by NICICO, the two locations finally selected had the following characteristics: • Topography of the selected sites was most favorable of all sites considered in the eastern and western parts of the mine. However, Heap No. 2 is located on a steep slope that required more earthworks construction and its associated higher costs to provide an acceptable leach pad slope. Heap No.1 is on a much flatter slope. • The required storage area available at the two selected sites exceeds that of the other sites. The second heap leaching area extends over 300,000 m2 in a steep valley situated at the western side of the mine.  Schematic illustration of base liners used at Sarcheshmeh’s leach pads. Source: Karimi Nasab S., M. R. Mollaei Fard, et al., 2003, “Stability Analysis of the Second Site of the Sarcheshmeh Heap Leaching,” 18th Mining Congress of Turkey. • Site selection of both heaps satisfied the requirements for reason able distance to the dumped ore from an ore haulage economics standpoint. • Both heaps offer safe hydrogeological conditions. • Heap No. 2 is near the mine, while Heap No. 1 is located far from the mining operation area. • A double-layer liner system was used in the construction of both heaps, minimizing the possibility of seepage of chemical solutions. • No vegetation or wildlife exist near the heap sites. • According to the information available, neither of the two selected sites sat atop economic mineralization. • Because the copper complex already owned the land on which both sites were located, permitting was not a problem. Results of maximum acceleration measurements show relative stability of heap leach pads and the behavior of the foundation, construction and stored materials under normal mine blasting conditions. However, Heap No. 2 will be closer to the mining area as the mine expands. As a result, careful studies are necessary to evaluate long-term stability of the heap site and modify blasting patterns if necessary. |