Depth to mineralization at BHP Billitonís new Spence copper mine in northern Chile ranges

from 80 m to 100 m below surface. (Photo: BHP Billiton)

BHP Billiton Inaugurates Spence Copper Operations

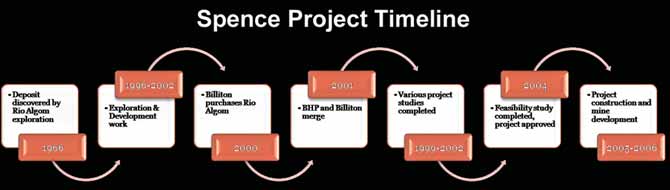

Spence is the first large-scale, greenfield mining project to be developed in Chile in six years and the first large SXEW project constructed globally since 2000. The project delivered its first ore to the crusher in September 2006 and achieved mechanical completion in early November. The tankhouse produced its first cathodes on Dec. 24, 2006.

The Spence project is located at an elevation of 1,700 m above sea level 150 km northeast of the port of Antofagasta and 50 km southwest of the city of Calama. The project site is situated alongside the main highway, rail line, and water pipeline that connect the two cities. Project design and construction benefited from BHP Billiton’s experience at its Escondida oxide project and Cerro Colorado mine in Chile, as well as at the Tintaya oxide project in Peru, which the company sold to Xstrata in 2006.

Spence is a supergene-enriched and partially oxidized porphyry copper deposit of Upper Paleocene age. Prior to development, it was 100% covered by gravels. Depth to mineralization ranges from 80 m to 100 m below surface. Oxide and supergene sulphide mineralization (atacamite and chalcocite) is amenable to heap leaching.

As of June 2006, proven and probable oxide ore reserves at Spence totaled 74.8 million mt, grading 1.24% total copper and 79% soluble copper. Sulphide ore reserves totaled 238.3 million mt, grading 1.08% total copper, with no figure available for soluble copper.

Aker Kvaerner was the Spence project EPCM contractor. Ninety percent of the engineering was undertaken in Chile, and 99% of the management team are Chilean nationals. The construction workforce peaked at 8,500.

The current Spence mine plan assumes a mine life of 19 years at a life-ofmine strip ratio of 3:1, waste to ore. Mine pre-strip totaled 73 million mt. The mining rate in the pit, including waste removal, will peak at about 260,000 mt/d. The designed ore treatment rate is 50,000 mt/d.

Primary mining equipment includes three Pit Viper drills, three P&H 65-yd3 shovels, two Caterpillar 994D 23-yd3 front-end loaders, and 25 Caterpillar 793C 240-mt haul trucks. Auxiliary equipment, all from Caterpillar, includes five 310T track dozers, two 834G wheel loaders, three 16H graders, and three 777E water trucks.

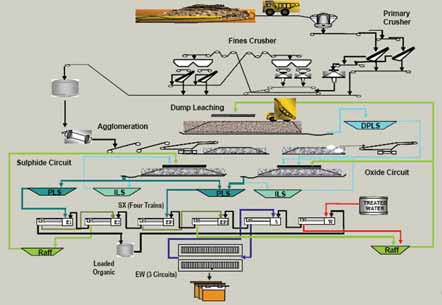

Ore from the pit is crushed, agglomerated, and transferred to on-off leach pads at a rate of 50,000 mt/d. Sulphide and oxide ores are leached on separate pads. Processing technologies and methods are similar to those employed by BHP Billiton at Cerro Colorado and Escondida. Cathodes are transported to either Antofagasta or Mejillones port facilities for shipping to customers in Europe and Asia.

BHP Billiton has an ongoing exploration program focused on identifying potential oxide and supergene sulphide mineralization for use as supplemental feed to the Spence plant. Within the Spence mining lease, a geophysics and drilling program is looking for satellite deposits at depth. Outside the lease, the company is exploring for potential mineral resources within an economic distance of Spence that are amenable to leaching. The company also is conducting a drilling and metallurgical test program to delineate and characterize the hypogene mineralization that underlies the current Spence mine.